Summary

- Learn five practical steps to optimize workflows, reduce waste, and increase output.

- Discover tools and strategies that help teams work with more consistency.

- Get monthly industry insights straight to your inbox. Subscribe to our newsletter!

Managing textile production demands clarity, coordination, and smart decision-making every day. You deal with tight deadlines, multiple workflows, and constant pressure to deliver high-quality results.

When processes aren’t aligned, delays and unnecessary costs appear quickly. But when everything flows, your team performs better and production becomes more predictable.

This article breaks down how textile production works and shows simple steps to optimize each stage. You’ll see how small adjustments create faster routines and more reliable outcomes.

Happy reading!

Sumário

Why is it important to understand all stages of the textile production process?

A complete view of the production chain helps managers identify where delays, waste, or quality problems begin.

Clear visibility also supports more confident decision-making, since every step of the process becomes easier to interpret.

This knowledge strengthens time management as well. With the full sequence mapped out, it becomes simpler to plan workloads, coordinate teams, and organize deliveries. That level of control is crucial in the textile industry, where agility directly affects competitiveness.

Understanding the workflow also improves how you handle resources.

Knowing how each stage uses materials makes it easier to manage raw materials with more precision. This leads to lower costs and more sustainable practices.

How does the textile production process work?

The textile production process follows a series of structured steps that turn ideas into garments. Each stage builds on the previous one, creating a flow that depends on good coordination.

Take a look:

1) Collection planning

Collection planning defines the direction of the entire season. It sets the styles, quantities, timelines, and material needs so teams can follow a clear roadmap from start to finish.

This preparation avoids surprises and establishes the foundation for organized production.

A detailed plan also improves cost control and helps anticipate risks. Decisions about suppliers, schedules, and volumes of finished fabric are made early, reducing uncertainty during execution.

In addition, strong planning improves alignment across departments. With clear goals and well-defined tasks, production teams perform better and maintain a steady rhythm throughout the season.

Read more: 5 strategies for production planning in the fashion industry

2) Design and prototype development

This stage brings creativity, planning, and technical insight together.

Design teams explore trends, sketch new concepts, and define the aesthetic direction of the collection. They choose fabrics and trims, and colors with care, making sure every element aligns with the goals of the season.

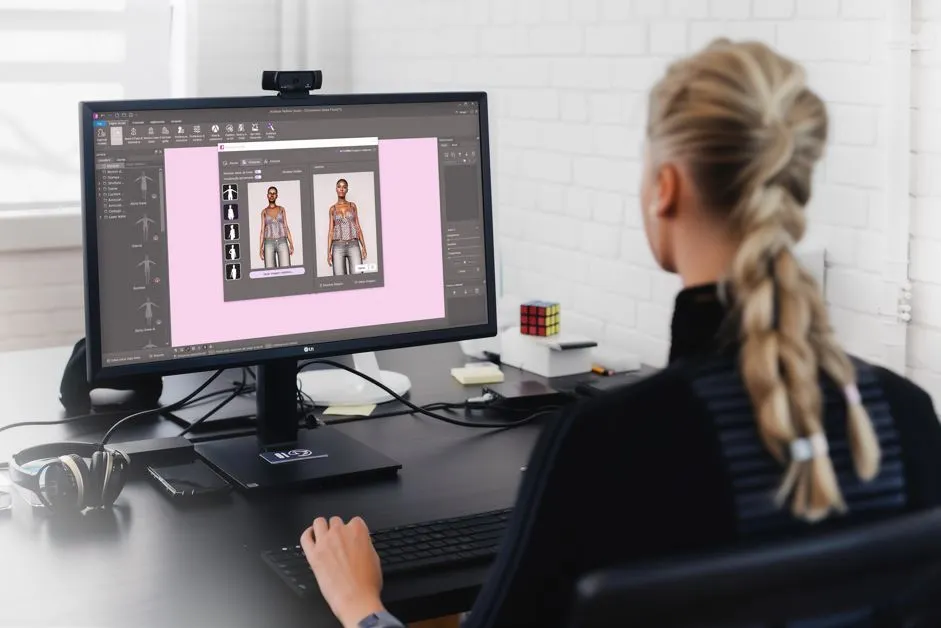

During prototype development, teams turn these ideas into tangible tests. They create 3D simulations or physical samples to study how materials behave and how the garment fits.

This moment allows Design and Development teams to collaborate closely, refining shapes, adjusting proportions, and improving construction techniques.

Prototypes also give teams a strategic advantage. They detect flaws early, compare alternatives, and secure feedback before investing in large-scale production.

Read more: 6 signs you’re ready to move to 3D prototyping

3) Pattern and marker making

Pattern making translates creative ideas into precise technical structures. Measurements, lines, and shapes must be accurate to guarantee consistent garment quality across all sizes. Strong technical work here reduces rework and ensures a better fit.

Meanwhile, marker making focuses on fabric efficiency.

By organizing pattern pieces strategically, the team minimizes waste and saves material. A good layout has the power to increase both productivity and cost-effectiveness.

Together, these two steps form a solid technical base for the entire operation. A reliable foundation here supports faster cutting, easier assembly, and better results.

Read more: Explore clothing pattern making techniques for your production

4) Fabric cutting

This stage transforms digital or manual patterns into fabric components. Precision is critical, because any error at this point affects the entire production line.

To solve any potential issue, good practices support high quality and help avoid material loss.

Technology, for example, makes the cutting room more accurate and efficient. Automated systems align layers, handle complex fabrics, and ensure uniform results at scale.

This creates smoother routines for the teams that follow.

Read more: Benefits of investing in an automatic fabric cutting machine

5) Sewing and finishing

Sewing gives structure to the garment. Teams or machines assemble the pieces with attention to durability, comfort, and overall construction. The quality of this stage defines most of the final fit and appearance.

At the same time, finishing brings refinement to the piece. Pressing, trimming threads, labeling, and performing checks guarantee that every detail meets your standards. This extra attention ensures reliable results batch after batch.

The outcome is the finished product ready for the market.

Ready to take your production to the next level? This fashion e-book holds powerful insights! Download it now and unlock new growth opportunities.

How to optimize the process of textile production

Optimizing the textile production process starts with understanding how each step contributes to efficiency, quality, and consistency.

Here’s a simple five-step guide to help you evaluate your current workflow and boost your production efficiency:

Standardizing production steps

Standardization creates stability across the entire operation. Clear instructions, repeatable workflows, and documented procedures minimize variations and help the team maintain quality at scale.

A consistent routine also reduces rework and avoids confusion, especially in complex environments.

Stronger standards support better training and faster onboarding. New employees understand what to do from the first day because every stage is predictable.

This is especially valuable in the textile manufacturing process, where small inconsistencies can interrupt the flow of production.

Read more: Discover the main types of automation transforming fashion

Tracking the process from end to end

End-to-end tracking gives managers the visibility they need to make smarter decisions.

As you follow each step in real time, you can see where delays start and which activities demand immediate attention. This level of insight strengthens daily operations and creates a more predictable routine.

Complete visibility also helps managers connect all processes involved in textile production. It’s possible to identify bottlenecks, align priorities, and adjust production plans before small issues grow into major rework.

With this approach, the entire operation gains speed, consistency, and a stronger foundation for continuous improvement.

Automating operational activities

Automation removes repetitive tasks from your team’s routine, allowing employees to focus on higher-value work. Cutting, grading, and data entry are examples of areas where machines can perform tasks faster and with greater precision.

By reducing manual steps, you also reduce the risk of human error.

Automated activities follow the same logic every time, which leads to consistent results and fewer interruptions. Production becomes more predictable, especially during periods of high demand.

In addition, automation creates a more scalable structure. As orders increase, the system helps absorb the extra workload without overwhelming your team.

A well-automated operation adapts quickly to new challenges and maintains quality even with tight deadlines.

Read more: 8 ways to adopt Industry 4.0 technologies in fashion

Using advanced technology

Advanced technology acts as a foundation that supports creativity and operational efficiency. Digital pattern making, automatic cutters, and AI-powered tools allow teams to work with accuracy and speed.

Modern systems integrate data and workflows, helping managers make informed decisions.

Real-time information strengthens scheduling, resource allocation, and quality control. With better insights, production becomes more resilient and adaptable to change.

Investing in advanced technology also positions your company for long-term growth. As competition increases, the brands that innovate gain an edge in efficiency, sustainability, and product quality.

Technology becomes a strategic advantage, not just an operational improvement.

Read more: Why should your company invest in fabrication technology?

Accelerate your process of textile production with Audaces solutions

Audaces360

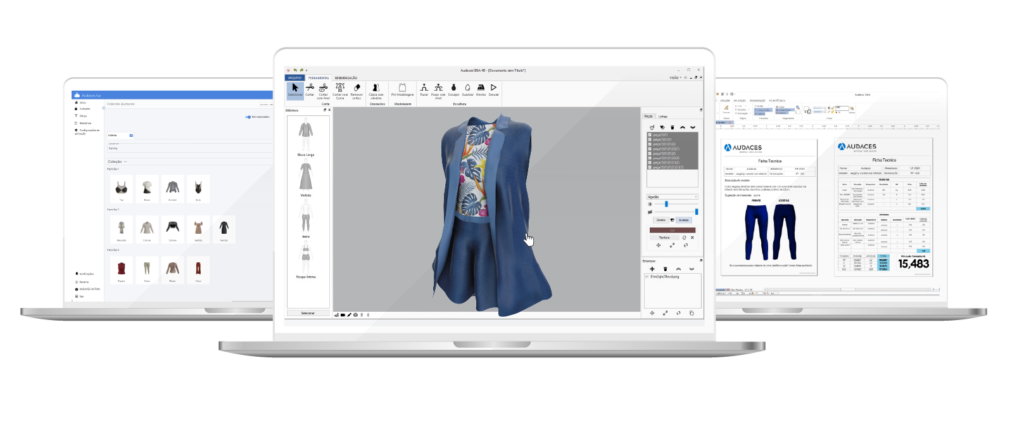

Audaces360 integrates cutting-edge digital innovations to optimize workflows in the textile and apparel industry.

It caters to companies of all sizes and types, offering the flexibility to scale with your business needs.

All solutions were carefully developed to address the specific challenges of the field. They streamline the design and production processes, saving valuable time and resources.

The platform boasts a comprehensive range of functionalities, including pattern making, marking, collection management, vector drawing, and 3D creation.

In addition, a fashion Artificial Intelligence to assist you along the way.

Discover Audaces solutions and unlock a world of possibilities from fashion design to sales. Explore our comprehensive suite of solutions today!

FAQ

A complete view of the production chain helps managers identify where delays, waste, or quality problems begin. Clear visibility also supports more confident decision-making, since every step of the process becomes easier to interpret.

The stages include collection planning, design, prototype development, pattern and marker making, fabric cutting, sewing, and finishing.

You can standardize steps, track the process from end to end, automate operational activities, and use advanced technology.