Summary

- Learn how efficient processes reduce costs and lead times.

- Discover key technologies and KPIs for better decision-making.

- Get monthly insights straight to your inbox. Subscribe to our newsletter!

Garment manufacturing requires increasing levels of precision, speed, and control to remain competitive in today’s market. Even small inefficiencies in the production flow can impact costs, delivery times, and product quality.

In this article, we’ll discuss how efficient processes play a crucial role in improving productivity and minimizing waste. We’ll also see the importance of integrating all stages of production, from designing to cutting.

Finally, the focus turns to the role of technology and key performance indicators (KPIs) in garment manufacturing.

We hope this brings you valuable insights. Enjoy your reading!

Sumário

How can I optimize my garment manufacturing?

Optimizing garment manufacturing starts with understanding how each stage of production connects to the next.

Design, pattern making, cutting, and sewing cannot work in isolation. When processes flow together, production becomes faster, more predictable, and easier to scale.

Another essential factor is process standardization. Clear methods reduce errors and make training easier. This approach aligns closely with lean manufacturing, which focuses on eliminating waste, improving efficiency, and creating continuous improvement across the factory floor.

Data also plays a key role in optimization. Tracking performance helps identify bottlenecks, delays, and unnecessary costs.

With reliable information, managers can make decisions based on facts, not assumptions.

Finally, optimization depends on mindset. Companies that view garment production as a dynamic system, rather than a sequence of tasks, gain control and profitability.

What defines an efficient garment manufacturing process?

An efficient garment manufacturing process combines speed, accuracy, and consistency across all production stages. Below, key elements explain how this efficiency is built in practice and how it can be sustained over time.

Integrated workflows

Integrated workflows ensure that information moves smoothly from one stage to the next. Pattern making, grading, and cutting should share the same data to avoid mismatches and manual rework.

When teams work with connected systems, decisions happen faster. Adjustments made in one area automatically reflect across the workflow, helping companies react quickly to changes in demand or materials.

As a result, integration plays a direct role in reducing lead times, improving delivery reliability, and increasing overall production efficiency.

Read more: 5 steps to optimize your process of textile production

Advanced technology

Digital tools reduce manual steps and bring greater precision to every phase of manufacturing.

Automation and software integration help standardize operations while maintaining flexibility. This balance allows companies to manage a wide range of styles, sizes, and materials without compromising speed or quality.

Technology also improves visibility. Real-time data enables teams to monitor progress, detect issues early, and optimize resource allocation throughout the production cycle.

Over time, these tools support scalability. As demand grows, technology makes it easier to expand operations without increasing complexity or operational risk.

Read more: Your guide to the best apparel manufacturing software

Clear and efficient communication

Clear communication aligns teams around goals, deadlines, and quality standards. Without it, even well-structured systems can fail.

Digital platforms centralize information and reduce misunderstandings. Everyone works with the same data, which strengthens collaboration across departments.

This clarity is essential for managing processes in garment manufacturing, where timing and precision directly affect costs and delivery performance.

Read more: Learn how to improve production and productivity in fashion

How can I integrate pattern making, marking and cutting?

Integration begins with using digital pattern making tools that connect directly to marking and cutting systems. When pattern data flows automatically into marking software, material usage becomes more efficient. Layouts adjust quickly based on fabric width, grain, and production needs.

In mass production, this integration is critical. Small inefficiencies multiply at scale, making accuracy and consistency essential for profitability.

Cutting machines also benefit directly from integrated data. Precise markers ensure clean cuts, less waste, and better alignment with sewing requirements.

Ultimately, a connected workflow strengthens the entire cutting process, delivering faster production, better fabric usage, and higher-quality garments.

Worried about implementing new technology in your production? Don’t be! Discover how to do it smoothly while keeping your operations running. Download our resource to learn more!

How can my company ensure accuracy and speed in the cutting stage?

Everything starts with well-developed patterns and markers that reflect real production conditions. Errors at this point tend to multiply later, affecting sewing quality and delivery times.

Standardized procedures also make a difference. Clear guidelines for fabric handling, alignment, and machine setup reduce variability. They also help operators work faster without compromising precision when they cut fabric.

Technology plays a central role in improving consistency. Automated cutting solutions follow predefined parameters and repeat them exactly, even across large production volumes.

Another important factor is layout optimization. Efficient markers reduce fabric waste and shorten cutting cycles. When teams work with accurate layouts, they spend less time correcting mistakes and more time producing.

Finally, continuous monitoring ensures ongoing improvement. By analyzing performance data and adjusting workflows, companies can speed up operations while maintaining accuracy.

Read more: Discover how machines that cut fabric can improve production

Which performance indicators should I track in garment manufacturing?

Tracking the right performance indicators helps manufacturers understand efficiency, costs, and production quality.

These are the key metrics that provide a clear view of garment manufacturing performance:

Lead time

It measures how long it takes to move from order confirmation to delivery. Shorter lead times indicate efficient workflows and strong coordination between departments.

This indicator helps identify delays across pattern making, cutting, sewing, and finishing. When lead time increases, it usually signals bottlenecks or communication gaps.

Monitoring lead time also supports better planning. With predictable timelines, companies can commit to delivery dates with greater confidence and reduce last-minute adjustments. Over time, consistent lead time reduction strengthens competitiveness in the market.

Fabric yield

Rather than looking only at consumption, it helps manufacturers understand how layout decisions, marker quality, and cutting accuracy affect overall efficiency.

Low yield often points to poor marker efficiency or cutting inaccuracies. On the other hand, a high yield usually reflects well-optimized layouts. It also means consistent cutting standards and better control over fabric behavior throughout production.

Because fabric is one of the most significant raw material costs, even small gains in yield can generate meaningful savings.

Read more: How can mass production boost your apparel manufacturing?

Cost per garment

Cost per garment represents the full expense involved in producing a single unit, from materials and labor to energy use and operational overhead.

Because it consolidates multiple variables, it offers a realistic view of production efficiency.

When this number starts to rise, it often signals hidden inefficiencies in daily operations. Process changes, unplanned rework, or poor material usage can all affect costs, even when production volume remains stable.

Beyond internal control, this indicator plays a strategic role in pricing. Knowing the true cost of each finished product allows brands to define prices that sustain margins while remaining competitive.

Rework rate

It shows how frequently garments need adjustments or corrections once production is already underway. When this indicator is high, it rarely reflects a single mistake and usually points to structural problems earlier in the workflow.

Pattern inconsistencies, cutting deviations, and unclear technical instructions are common sources of rework.

These issues disrupt production flow, increase handling time, and drive costs up with every additional correction.

Monitoring rework rate shifts the focus from correction to prevention. Instead of reacting to errors, companies can strengthen upstream processes and protect efficiency across the entire production cycle.

How does digitalization transform garment manufacturing?

Digitalization reshapes how information moves across the garment manufacturing industry.

Instead of fragmented steps and manual handoffs, production operates as a connected system where data flows continuously from design to manufacturing.

This shift changes daily operations. Digital tools link design, pattern making, and production planning, reducing repetitive tasks and minimizing interpretation errors.

As a result, teams work with consistent information across collections, even as complexity increases.

One of the most practical gains appears in the use of pattern markers. Automated layout generation improves fabric utilization while cutting down preparation time, especially in environments that handle frequent style or size changes.

Decision-making also becomes faster and more confident. Digital environments allow teams to test adjustments, simulate scenarios, and evaluate outcomes before committing changes to the production floor.

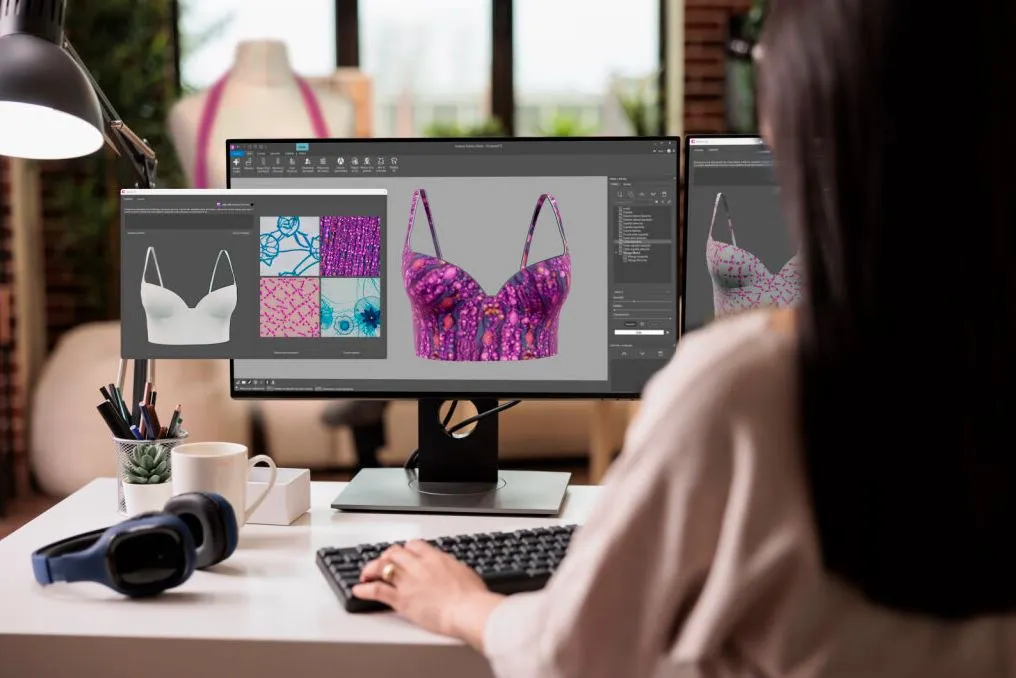

With computer aided design (CAD), patterns are easier to modify, grade, and standardize. This flexibility supports faster responses to market shifts without sacrificing fit or technical accuracy.

Rather than simply accelerating processes, digitalization strengthens control and transparency. It enables companies to scale operations, protect quality standards, and meet tighter deadlines with greater consistency.

Read more: Master the use of industrial patterns in apparel production

Boost your production with the best technology available

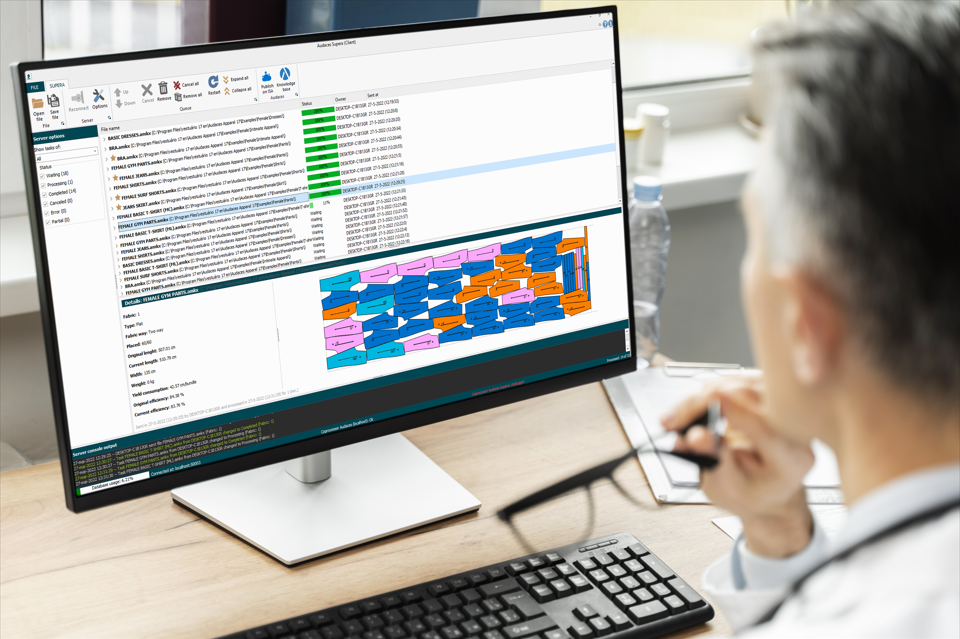

Audaces Cutting Room

By embracing cutting-edge technology, garment manufacturers can achieve significant improvements in the production process. From greater design flexibility to enhanced efficiency and reduced costs.

This is where Audaces Cutting Room steps in. Our experts will thoroughly assess your company’s needs and create a comprehensive report.

Then, our team will develop a personalized project to achieve your goals and unlock your company’s full potential.

Rely on Audaces’ cutting-edge machinery to automate your production process. Achieve impeccable cuts on curves and details, speeding up your deliveries and minimizing fabric waste through automation.

Audaces360

Audaces360 integrates cutting-edge digital innovations to optimize workflows in the textile and apparel industry.

It caters to companies of all sizes and types, offering the flexibility to scale with your business needs.

All solutions were carefully developed to address the specific challenges of the field. They streamline the design and production processes, saving valuable time and resources.

The platform boasts a comprehensive range of functionalities, including pattern making, marking, collection management, vector drawing, and 3D creation.

In addition, a fashion Artificial Intelligence to assist you along the way.

Success Story

Innovation and technology go hand in hand — and Audaces leads the way. We created the first platform to integrate every step of fashion production, from design to sales. This way, we can help brands achieve smarter and faster results.

Discover the story of how a major women’s fashion company reinvented its business with our solutions!

Want to achieve these results too? Click here and get in touch with one of our consultants.

FAQ

Optimizing garment manufacturing starts with understanding how each stage of production connects to the next. When processes flow together, production becomes faster, more predictable, and easier to scale.

An efficient process includes integrated workflows, advanced technology, and clear communication.

The KPIs for apparel manufacturing include lead time, fabric yield, cost per garment, and rework rate.