Summary

- Mass production is the most efficient way to leverage your company’s infrastructure and labor force.

- It allows you to compete in the market with affordable prices and a higher profit margin, leading to increased revenue.

- Access everything you need for your company to grow in one place. Try Audaces360 multisolution for free!

Mass production has become the dominant manufacturing approach across various industries, including the fashion and textile sectors.

This method involves producing large quantities of goods at a rapid pace, making it a cost-effective and efficient way to meet consumer demand.

To fully grasp the concept of mass production, its advantages, and how to implement it in your company while maintaining quality standards, delve into our comprehensive guide.

Enjoy your reading!

Sumário

Why adopt mass production for your apparel manufacturing?

While personalization is a growing trend in fashion, mass production remains a powerful tool for expanding your market reach and maximizing your business potential.

By leveraging Industry 4.0 principles and integrating the right processes, tools, and equipment, you can transform your production into a non-stop engine of efficiency.

Imagine a production line humming with activity, churning out apparel batches simultaneously.

This translates to rapid output, allowing you to nimbly adapt to ever-changing market trends. If a trend takes off, you can seamlessly scale up production to meet the surging demand.

Mass production also unlocks the power of design variation, allowing the production of a single design in different sizes, fabrics, and colors – all while maintaining consistent quality standards across every item.

This uniformity ensures that each garment reflects the same level of excellence, regardless of size or material.

By embracing mass production, you can reach a wider audience with affordable, high-quality garments that cater to diverse tastes and preferences.

Additionally, it allows for efficient utilization of labor, machinery, and raw materials, maximizing production output while minimizing waste.

Learn more: Explore the benefits of industrial technology in the fashion sector

What is apparel mass production?

Also known as serial, large-scale, and batch production, mass production definition is the high-volume manufacturing of items using standardized processes and equipment.

The main characteristics include:

- Large quantities: this is the primary goal of mass production, prioritizing quantity over customization.

- Standardization: processes, materials, and components are standardized for speed and quality.

- Division of labor: complex tasks are broken down into smaller steps to increase efficiency.

- Automation: machinery and automation software can significantly speed up the manufacturing process.

- Economies of scale: by producing large volumes of garments, the cost per unit of production decreases, allowing for lower prices for consumers and higher profit margins for businesses.

The idea that high-volume production means sacrificing quality is a common misconception. In fact, it can be achieved successfully.

Bulk buying power allows manufacturers to leverage their purchasing power with suppliers, securing top-tier raw materials at competitive prices.

Furthermore, investments in modern equipment and software ensure consistent quality, precision, and efficiency throughout the production process.

However, overproduction – producing more than you can sell – is a major risk. Excess inventory ties up capital, impacting cash flow and hindering business growth.

To mitigate this risk, thorough market research and sales forecasting are crucial before launching collections. This allows for a more accurate production plan that aligns with projected demand.

In the event of excess inventory, Sales and Marketing teams often step up to develop targeted strategies to move the stock. This may involve promotions, discounts, or exploring new sales channels.

Learn more: Explore challenges and opportunities to excel in fashion retail

Benefits of apparel mass production

Now that we’ve explored the general advantages and potential drawbacks of mass production, let’s delve deeper into the specific benefits it can offer your apparel manufacturing:

Cost reduction

Mass production leverages the power of economies of scale. As your production volume increases, the cost per unit decreases, which translates to a higher profit margin on each item sold.

This happens because fixed costs, like machinery and infrastructure, are spread across a larger number of garments.

Lower production costs translate into the ability to offer products at competitive prices, broadening customer reach and solidifying market position.

This increased profitability can be reinvested in various areas, such as enhancing product quality, exploring innovative design elements, or expanding product lines.

Moreover, by utilizing real-time demand data, you can adjust production volumes to optimize inventory and avoid overproduction.

Learn more: Discover how to reduce costs in wholesale clothing production

Easy scalability

Both production and sales are easily scalable due to standardization.

Standardized processes allow for replicating production lines quickly, enabling you to ramp up or down based on market demand.

Once optimized, these processes can be replicated across multiple production units with minimal adjustments.

Beyond production, efficient marketing, logistics, and distribution networks play a key role in scaling sales.

By ensuring efficient marketing campaigns and cost-effective transportation and delivery of finished products, mass production facilitates smooth sales growth.

Learn more: Discover how to enhance productivity in the textile business chain

Efficient manufacturing

Mass production breaks down the production process into specialized tasks performed by skilled workers and automated systems.

This division of labor allows for increased efficiency and productivity. Workers become experts in their assigned tasks, minimizing errors and maximizing output.

Furthermore, mass production fosters a culture of continuous improvement and innovation.

Manufacturers constantly seek ways to optimize processes, reduce waste, and enhance product quality.

This commitment to innovation leads to long-term efficiency gains through new technologies, refined production methods, and best practices.

Learn more: 5 strategies to optimize your production with efficient fashion

Production agility

Many mass production businesses embrace lean manufacturing principles, which aim to minimize waste, improve efficiency, and increase flexibility.

Moreover, advanced technologies like automation solutions, smart equipment, and data analytics can enhance agility by enabling real-time monitoring and adjustments to the production process.

By constantly striving for improvement, manufacturers can reduce lead times, increase production speed, and respond more quickly to market changes.

While some customization options might be limited, mass production still allows for easier adjustments or adaptations by reconfiguring lines or making minor product changes to better meet consumer needs.

How to maintain quality in mass production?

Maintaining quality in mass production is essential for customer satisfaction and brand reputation. From sourcing materials to final inspection, every step must uphold quality standards.

It requires rigorous quality control measures, standardized processes, and continuous improvement.

Let’s explore some key strategies:

Using technology for design

CAD software, for example, provides tools for creating detailed technical specifications and patterns.

This ensures consistency and eliminates errors, leading to a more uniform and high-quality product across all manufactured items.

Additionally, technology like 3D design allows for the creation of highly precise digital simulations of garments.

This enables professionals to identify potential fit and design issues early on in the development process, leading to more accurate and consistent quality in the final product.

Learn more: How does technology in fashion impact the textile industry?

Managing the collection end-to-end

End-to-end management of the collection process, from development to production, fosters a smooth and organized flow of information and tasks.

This eliminates redundancies, minimizes bottlenecks, and ensures everyone involved is working toward the same goals.

Real-time management offers a significant advantage. It allows for immediate identification and resolution of issues as they arise, preventing delays and rework.

Additionally, valuable data can be collected at every stage of the process.

By analyzing this data, businesses can identify areas for improvement, optimize processes, and make informed decisions regarding future collections.

Maintaining control throughout the entire process ensures consistent quality standards across all aspects of the collection.

Learn more: 6 benefits of having an online collection management

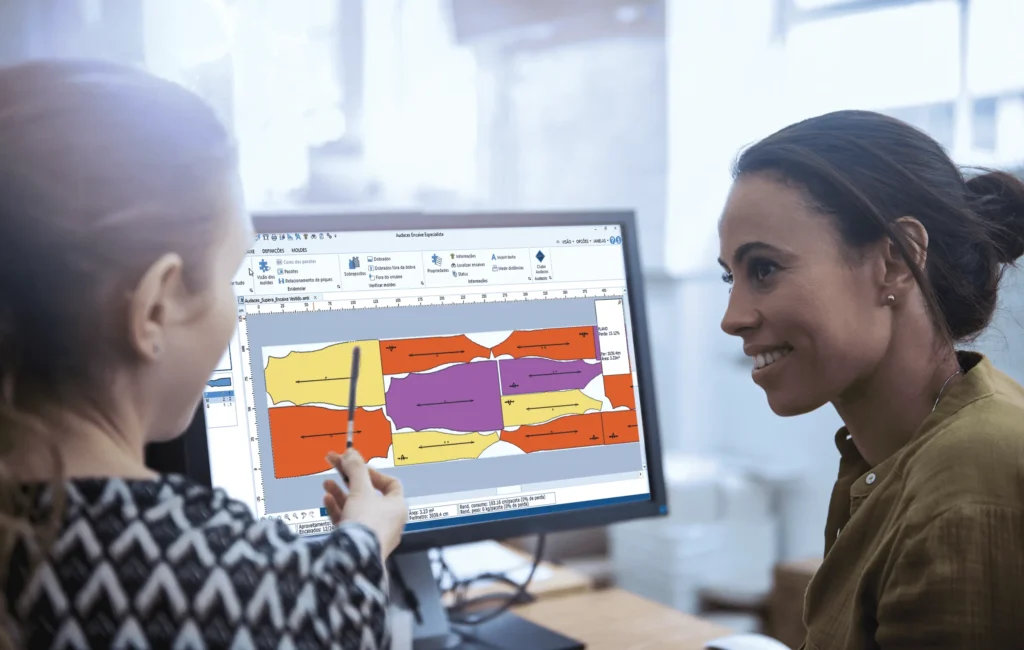

Optimizing markings

When it comes to mass production, achieving efficiency and minimizing waste are top priorities. This is where the often-overlooked process of marking steps into the spotlight.

One of the inherent advantages of high-volume production is the frequent use of the same fabric across multiple garment designs. This presents a unique opportunity for marking optimization.

By creating long spreads, essentially large layouts that accommodate various patterns from different styles, manufacturers can significantly reduce the time required for marking each design.

Beyond the time-saving advantage, optimized marking offers a crucial benefit: superior fabric utilization.

Traditional methods often leave behind significant amounts of unused fabric scraps.

However, by carefully planning and utilizing long spreads that consider pattern shapes, grain direction, and minimizing dead space, marking optimization allows for maximizing the amount of usable fabric from each roll.

This translates to substantial cost savings, especially when dealing with expensive fabrics.

Automating cutting

Automated cutting machines operate at significantly higher speeds compared to manual cutting processes.

They can easily handle large production volumes, making them ideal for mass production scenarios.

Additionally, they can be readily scaled up or down to meet fluctuating production demands.

This results in faster turnaround times for garment production, allowing manufacturers to meet higher demand and capitalize on market trends.

This kind of technology is programmed to follow precise digital patterns, minimizing the risk of human error that can occur during manual methods.

The automation of this process ensures consistent quality and accurate garment sizing across all produced items, ensuring a smoother and more efficient flow of materials throughout the production line.

Make your mass production more efficient with Audaces’ cutting-edge technology!

Audaces has established itself as a global authority in fashion technology, offering all-encompassing solutions for companies of any size and sector.

We leverage cutting-edge technology to develop software and equipment specifically designed to meet the most common challenges faced by apparel manufacturers.

Audaces Cutting Room

Our customized Audaces Cutting Room project delivers a cutting room specifically designed to match your unique production goals and demands.

A consultant will reach out to understand the intricacies of your company, and then provide a comprehensive diagnosis and a personalized quote for your cutting room.

Some of the significant advantages include enhancing both efficiency and accuracy with automated cutting technology, achieving consistent and precise garment cuts, minimizing waste, and guaranteeing quality.

Audaces360

Audaces360 stands as the most comprehensive software solution to optimize your entire creation, development, and production process.

It functions seamlessly from start to finish, connecting your team and simplifying workflow.

These are some of the key benefits:

- Design garments with precision using 2D vector tools, generating automated spec sheets and pre-costs.

- Visualize and refine your designs on a virtual mannequin.

- Leverage AI technology to enhance your design process.

- Manage your collection end-to-end from the palm of your hand.

- Create accurate and efficient digital patterns for production.

- Optimize fabric usage and minimize waste with automated marking.

Audaces Attiva

Audaces Attiva is an exclusive service offering comprehensive planning and implementation of intelligent solutions for the entire apparel manufacturing process.

This expert consulting service is designed specifically for companies seeking to improve their operations, but unsure of where to begin.

Audaces Attiva consultants will help you identify the best solutions to optimize your time and resources, ultimately boosting your profitability.

Learn how to make your apparel manufacturing more productive with our free ebook!

FAQ

While personalization is a growing trend in fashion, mass production remains a powerful tool for expanding your market reach and maximizing your business potential.

Also known as serial, large-scale, and batch production, mass production definition is the high-volume manufacturing of items using standardized processes and equipment.

Cost reduction, easy scalability, efficient manufacturing, and production agility.