Summary:

- Technology in fashion brings a massive impact on professionals of the textile sector. Differences are visible from clothing manufacturing until the distribution process.

- More than saving resources and time, technological innovations bring customers together around the fashion brand and keep them loyal.

- Intelligent software can be the starting point for clothing production with more agility and optimization for your collection creation. Get the free trial of Audaces360 multi-solution now and find out how!

Fashion and technology – name a more iconic match than that!

Relevant changes in the industry happened thanks to technology applied in fashion – from fashion shows held in virtual environments to realistic avatars for clothing fittings.

Traditional means, which can often generate larger budgets and longer time-spending, have been replaced by technological innovation that strives for the future.

Want to know more about how technology is changing the fashion industry? Stay with us for the following topics!

Sumário

Enjoy the reading and see how this scenario is already a reality.

The future is here and now, among us.

What is technology in fashion?

When we talk about technology in fashion, maybe people imagine shiny clothes full of exotic props or pieces changing colors according to the body temperature.

Well, it can, and it can’t be. But, in fact, what matters here are the benefits technology brings to garments and apparel. These gains range from clothing creation to the foundation of more sustainable practices in companies.

In addition to facilitating and bringing more agility to deliveries, technology generates experiences in augmented reality, fashion shows in the metaverse, and the rise of virtual clothes.

The pieces produced in a virtual environment facilitate customers’ daily lives and are multifunctional, bringing a sense of fashion with a purpose.

Learn more: 4 top tips for a successful fashion collection launch

The impacts of technology in textile production

Who seek agility and optimization of time and resources can count on technology to input many new features and advantages in all areas of textile production.

Technology in fashion has a major influence on the whole process of clothing manufacturing – from the creation to the sale, getting the launch and distribution of the collection, and making the products stand out at the POS.

Check out some positive impacts that your company might notice when inserting technology into the production routine:

Operational processes

Technical sheets, pre-cost calculation, modeling, and prototyping can all be done virtually.

Operational processes become much easier and faster when they make the most out of technology. Beyond well-organized communication between sectors, the entire work process gets documented, and, in case you need to look for something, all the professionals in charge will know exactly where to find it.

Learn more: Find out everything you need to know about 3D fashion design

Productivity

The productivity growth of clothing manufacturing is directly linked to its profit. Thus, by increasing one part, the other tends to rise as well.

Those who want to expand both aspects should invest in technological tools that assure good-quality creation, development, and production stages, coming up with the expected results.

When your company has organized processes, with the help of technology, your team gets more time to focus on what really matters.

Learn more: How digital fashion design works and what are the benefits for the clothing industry?

Sustainability

Studies show that, globally, around 92 million tons of textile waste are produced every year. According to the EPA Report, 16 million tons of fabric waste are generated by Americans each year, for example.

Technology in fashion enables fabrics, patterns, and pieces to be virtually created at first. That makes the process much more sustainable.

The designers can work on all the creations online, then approve and test them. That means a significant reduction in textile waste within the industry.

Competitiveness

More than making the fashion collection launches up to date, companies that long to become competitive in the market must look for technologies that facilitate and streamline the production chain.

Profitability

In addition to optimizing time and labor, technology can also optimize resources, bringing greater profitability. That’s because doing the main activities online helps save fabrics, paper, and other inputs.

If you have an e-commerce business, for examples, solutions like size and fit advisor can help reduce exchange and return costs. They do this by suggesting the correct size for the customer.

Top technological innovations applied to fashion

Technology values the clothing pieces – not only financially, but in terms of quality too.

More than beauty, fashion brings functionality. Technology in fashion provides and improves materials that benefit those who use them.

Virtual clothes

Virtual clothes are exclusive and exist only virtually.

Over time, they are no longer just part of gaming development and movies’ visual effects. Today, they come with new proposals, and the metaverse is a fine example. Now, stylists create clothing for avatars, which can be sold as NFTs or photo filters.

Learn more: What is virtual fashion design and why use it in your clothing business?

Technological fabrics

Technology has managed to produce fabrics from synthetic fibers. These fabrics bring more comfort, safety, and innovation to the pieces.

Check out below the main properties of these fabrics:

Anti-UV

Sunlight is vital to ensure human well-being, strengthening bones, and the production of vitamin D. However, when in excess, that can cause skin cancer.

Technology created in Australia, the anti-UV fabric started being used by athletes, but it became more popular even among people out of the sports universe.

This tech fabric protects the skin against ultraviolet rays, reaching up to UPF 50+. In addition, pieces made with the fabric undergo an aqueous chemical bath – which does not harm health – to reinforce the levels of protection.

However, it’s valid to note that not all fabrics need to go through this process. In some cases, the tissue structure itself generates protection.

These fabrics work like this: they reflect ultraviolet rays, preventing skin absorption when exposed to the sun. Those who wear garments with this type of protection don’t need to worry when going out in the sun: wearing anti-UV clothing is enough, and you’re good to go!

Anti-flame

A fabric that doesn’t burn? It already exists – and thanks to technology!

The flame-retardant fabric prevents combustion and fire spreading. Like anti-UV fabric, its production happens through a chemical process.

The anti-flame fabric has a discreet finish and can be used on different materials. But it is mainly used in the uniforms of professionals working with fire or electricity

Anti-bacterial

A type of fabric that prevents the proliferation of bacteria and fungi and eliminate odors, guaranteeing hygiene, comfort, and freshness. Way to go!

It can be synthetic or natural fiber made. Some pieces use this fabric more commonly – those that retain moisture, for example, such as sportswear, underwear, and swimwear.

Waterproof

Waterproof fabric blocks water from passing through the fibers, preventing stains, and making vivid colors last longer.

This type of fabric is made with a special cotton and polyester fibers. It creates a kind of resin, which is more resistant as it blocks liquids.

Despite this, the fabric doesn’t get a laminated texture or appearance. It’s actually soft and comfortable to wear.

3D printing

3D printing is voguing more and more in the fashion universe. It makes the piece’s manufacturing faster, simpler, and less expensive.

The outfits can be customized, adapting to the style and biotype of those who wear them.

Washing technology

To obtain the desired color in fashion items, they must undergo washing, which uses water and heavy metals, such as potassium permanganate, chromium, mercury, cadmium, lead, copper, and manganese.

These toxic residues leave the water with little chance of being reused. In addition, they possibly get in touch with rivers and oceans and accumulate toxicity, contaminating the soil.

The technology helps the textile industry to wash the pieces with less pollution

Research shows that a discarded substance by the food industry, chitosan – found in the exoskeleton of crustaceans – improves the absorption and fixation of the indigo color on jeans. This process exempts various washing steps required for the fabric to obtain the desired color.

Some companies are already working with technologies that use laser light to imitate, even if digitally, types of washing effects.

Speaking of that, there are also dry washing processes that use wind power. This technology gets the air from the atmosphere and transforms it into ozone, releasing particles that act on the fabric and remove excess ink.

Learn more: What is digital clothing and how does it impact the fashion industry?

How Audaces technology can be applied to your textile production?

Technology in fashion can bring many advantages to companies in the textile industry. In addition to saving time and resources, some software can also bring agility to various processes of fashion making.

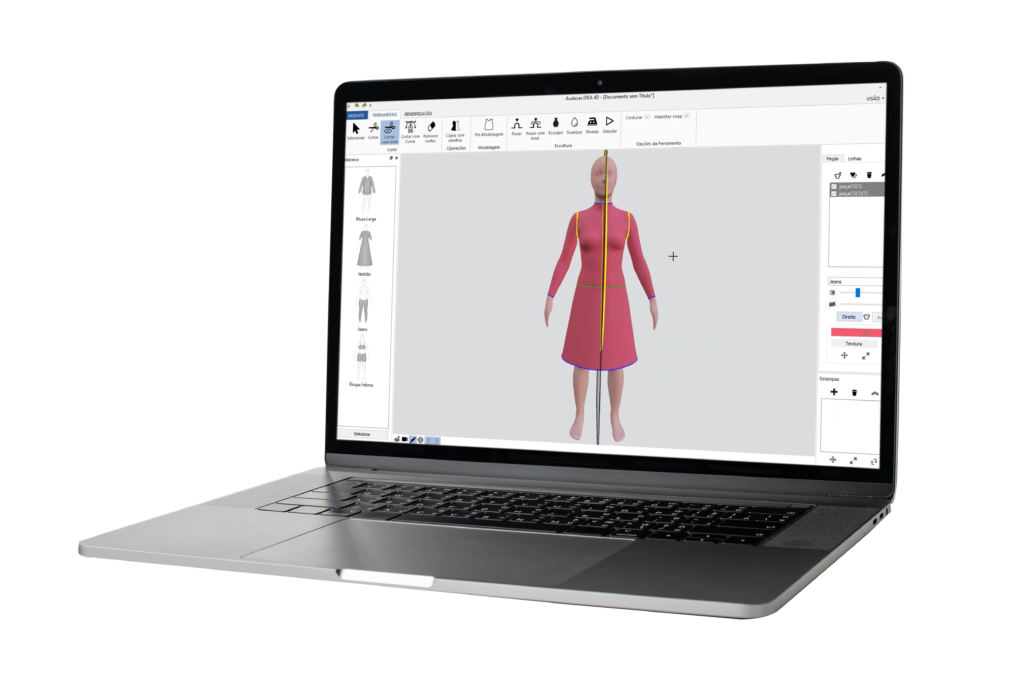

Whether in washing or technical procedures, we can use technology throughout textile production – and Audaces can help you to make this happen in your business!

We have solutions that bring an innovative concept that integrates several stages from Creation to Production for you to achieve the best results!

Audace360 is a complete platform that overcomes challenges.

With Audaces360 you can integrate all the creative and productive steps of your clothing manufacturing, ensuring your fashion collection will be a blast!

A technology that brings results with more practicality, ensuring optimization for your company’s daily routine.

Want to see everything Audaces can do to put your company a step closer to the future? Then download our free e-book right now:

FAQ

In addition to facilitating and bringing more agility to deliveries, technology generates experiences in augmented reality, fashion shows in the metaverse, and the rise of virtual clothes.

Operational processes, productivity, sustainability, competitiveness, and profitability.

Virtual clothes, technological fabrics, anti-UV, anti-flame, anti-bacterial, waterproof, 3D printing, and washing technology.

2 Responses

Nice

Thank you for your feedback!