Summary

- Machines that cut fabric are essential for speed, accuracy, and waste reduction in textile production.

- Choosing the right machine depends on your needs, production scale, and desired results.

- Want to take your company further? Subscribe to our newsletter for exclusive insights!

Fabric cutting is one of the most important stages in garment production. It defines the usage of materials and how precisely each piece fits together during sewing. That’s why investing in reliable machines that cut fabric can make a real difference in your production line.

These machines come in many forms, from simple manual cutters to advanced automated systems. Each type serves a specific purpose and suits different business sizes and production demands.

Let’s explore the main types of machines that cut fabric, the industries that benefit most, and how to identify the best option.

Get ready to boost efficiency. Happy reading!

Sumário

5 types of machines that cut fabric

Not all machines that cut fabric are the same. Each one meets different production needs, materials, and levels of precision.

Choosing the right model can make a huge difference in your workflow and final results.

Let’s take a look at the main types and understand how each of them works:

1) Straight knife cutting machines

They use a vertically moving straight blade that easily slices through stacked layers of fabric. This makes them ideal for small to medium-scale production, especially in workshops that handle various materials and shapes.

Their main advantages are versatility and precision. Operators can guide the machine manually to achieve accurate cuts, even on complex patterns.

However, they do require skill and attention to ensure consistent results. The quality largely depends on the user’s handling.

2) Band knife cutting machines

Band knife cutting machines are similar in principle but use a continuous, rotating blade stretched between two pulleys. This design allows for smoother, more controlled cuts, perfect for delicate or flexible fabrics that might shift under a straight knife.

They’re common in sample rooms and pattern development departments, where precision and clean edges are key.

3) Die cutting machines

Instead of a moving blade to cut, they use a pre-shaped metal die to punch out specific patterns. It’s an excellent method for producing identical pieces in large quantities, such as labels, patches, or accessories.

Their biggest strength lies in repeatability. Once the die is ready, it can reproduce the same shape thousands of times with perfect accuracy. But creating new dies can be costly, so this type of machine is better suited for mass production of standard designs.

4) Laser cutting machines

These fabric cutter machines use a concentrated laser beam to cut with extreme accuracy. The laser seals the edges at the same time to prevent fraying. They are ideal for synthetic materials, intricate patterns, and high-end fashion.

Beyond precision, they also minimize material waste and don’t require physical contact with the fabric, which prevents distortion.

5) Automatic cutting machines

Automatic cutting machines represent the most advanced option available today.

These systems combine powerful blades with digital control software, allowing for precise and fast cutting of multiple fabric layers. They’re perfect for large-scale production environments that value speed and efficiency.

Integrated with CAD systems, automatic machines can read digital patterns directly, optimizing fabric usage and minimizing human error. They reduce manual work, improve consistency, and significantly cut down production time.

Read more: 6 benefits of a cutting room for your fashion manufacturing

Which industries benefit from machines that cut fabric?

Apparel

From small fashion studios to large garment factories, these machines are key to transforming fabric rolls into precise pieces. They help ensure that each pattern piece matches perfectly, maintaining consistent sizing and fit across entire collections.

Cutting machines also speed up production and minimize fabric waste. These are two essential factors for keeping costs under control and meeting tight deadlines.

Read more: How to overcome slow cutting in your apparel manufacturing?

Footwear and accessories

In footwear and accessories manufacturing, precision is just as important as in clothing production. Cutting machines shape fabric, leather, and synthetic materials for items like shoes, handbags, and belts.

The ability to follow detailed templates with exact measurements guarantees that each component fits seamlessly into the final product.

Read more: How can a good cutting plan transform your production?

Automotive

Here, they’re useful for upholstery, seat covers, interior panels, and insulation materials with millimeter-level accuracy. Given the high safety and durability standards of this sector, precision cutting ensures every piece meets strict quality requirements.

Automated systems are especially valuable for large production runs, where consistency and efficiency are crucial.

With advanced technology, manufacturers can optimize material use and reduce waste.

Read more: 7 key factors to look for in the best fabric cutting systems

Furniture

In the furniture industry, machines that cut fabric play a vital role in producing upholstery and decorative elements.

They ensure the cut of fabric pieces evenly and precisely, guaranteeing a neat finish and smooth assembly. From sofas to chairs and curtains, accurate cutting helps maintain comfort and aesthetics.

These machines can also process heavy or layered materials, such as foam-backed textiles or leather.

Ready to optimize your cutting room? Download our guide and learn how to eliminate costly mistakes!

What should a good machine that cuts fabric have?

Not every cutting machine offers the same level of performance.

When choosing a machine that cuts fabric, it’s worth considering key features that ensure long-term productivity:

High precision

A good machine must deliver clean, consistent cuts across all materials, ensuring that each pattern aligns perfectly during assembly. When pieces are perfectly cut, sewing becomes faster and fitting issues disappear.

High precision is especially important for complex designs or multilayer cutting. In these situations, even a small deviation can affect the final result.

Read more: Find out which 4 cutting tools are worth your investment

Ability to handle multiple layers and materials

A reliable cutting machine should work well with a variety of fabrics, from lightweight cotton to thick denim. It must also be able to cut through multiple layers at once without losing accuracy or damaging the material.

These abilities are essential for scaling up production while maintaining quality.

Integration with other systems

Modern fabric cutting machines should integrate smoothly with other digital systems, such as CAD software or production management tools. This connection allows you to import patterns directly, eliminating manual steps, and reducing the risk of errors.

Integrated systems also enable better planning and real-time monitoring of production. By connecting cutting machines to a digital workflow, companies can improve efficiency and track performance.

Read more: The ultimate 6-step guide to choosing cutting plan software

Easy operation

Operators should be able to set up and control the equipment without needing complex training. A simple interface and intuitive software help reduce errors and make daily work faster and safer.

Machines that are easy to operate also minimize downtime and help new employees adapt quickly.

Low maintenance and reliable technical support

A high-quality machine that cuts fabric should require minimal maintenance to stay in top condition. Durable components and smart design reduce the need for constant repairs, saving time and money in the long run.

Still, even the best machines benefit from having strong technical support behind them.

Reliable assistance ensures quick problem-solving and helps extend the machine’s lifespan. With low maintenance and expert support, you can keep production running smoothly and avoid unexpected delays.

How much does a machine that cuts fabric cost?

The cost of a machine can vary widely depending on its technology, cutting capacity, and level of automation.

Entry-level models, such as straight or band knife cutters, are generally more affordable and ideal for smaller operations. On the other hand, advanced options like laser and automatic cutting machines represent a larger investment. However, they deliver much greater speed, precision, and productivity.

When evaluating the price, it’s important to look beyond the initial cost. A high-quality machine can quickly pay for itself by reducing fabric waste and cutting production time.

What is the best machine that cuts fabric?

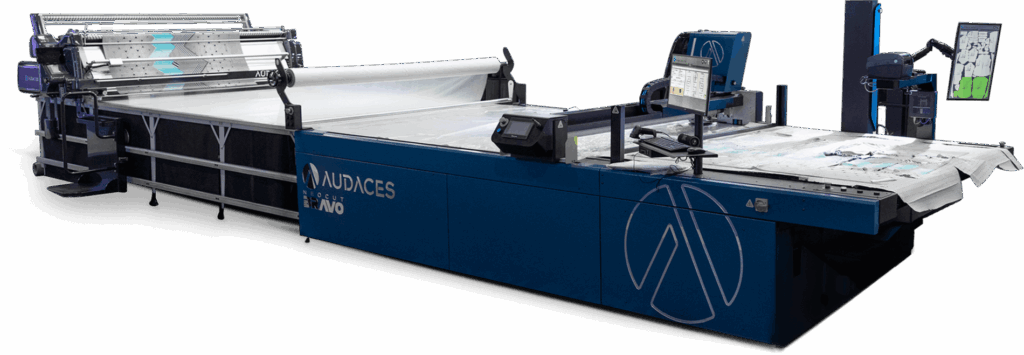

Among the leading options on the market, the Audaces Neocut Bravo stands out for its advanced performance and flexibility. You can use it on its own or as part of our cutting room, integrating with other solutions from Audaces.

This machine offers cutting-edge technology designed to optimize every step of the cutting process. It delivers clean, accurate cuts across multiple fabric layers, ensuring efficiency and consistency.

Its automation capabilities help eliminate manual errors while maximizing material use!

Increase your production with Audaces Cutting Room

By embracing cutting-edge technology, garment manufacturers can achieve significant improvements in the production process. From greater design flexibility to enhanced efficiency and reduced costs.

This is where Audaces Cutting Room steps in. Our experts will thoroughly assess your company’s needs and create a comprehensive report.

Then, our team will develop a personalized project to achieve your goals and unlock your company’s full potential.

Rely on Audaces’ cutting-edge machinery to automate your production process. Achieve impeccable cuts on curves and details, speeding up your deliveries and minimizing fabric waste through automation.

At first, this uniform company thought growth had to come before automation. But the Audaces Cutting Room proved they could achieve both together. See how in this success story!

FAQ

The main types include straight knife, band knife, die, laser, and automatic cutting machines.

Key industries like apparel, footwear, accessories, automotive, and furniture can benefit from machines that cut fabric.

They must have high precision, ability to cut multiple layers and materials, integration with other systems, and easy operation.