Summary

- In clothing manufacturing, every detail matters. From fabric selection to final touches, precision and efficiency make all the difference.

- Cutting is a crucial step that impacts quality, cost, and production speed. Choosing the right tools ensures smooth operations.

- Experience the future of the fashion industry with Audaces360. Sign up for your free trial today.

Picture this: You’re a production manager looking to make your processes more efficient. Investing in new industrial cutting tools might seem like the obvious solution.

You start searching and find that some tools promise speed. Meanwhile, others focus on precision, and some offer full integration with other processes. But which ones truly deliver results?

That’s exactly what you’ll discover in this text! The right choice can give you all these benefits at once, helping you streamline your workflow and boost production capacity.

Happy reading!

Sumário

Why invest in industrial cutting tools for your clothing manufacturing?

These tools help streamline the cutting process, reducing the time spent on each garment. By automating parts of the production, you can cut down on labor costs and minimize human error.

With the right cutting tools, you can also reduce waste. Precise cuts ensure you use fabric more effectively, reducing material costs.

In addition, the speed of industrial cutting tools allows you to keep up with higher production demands. All without compromising quality.

Learn more: 7 key factors to look for in the best fabric cutting systems

4 industrial cutting tools every clothing manufacturer should have

Every clothing manufacturer needs reliable cutting tools to ensure smooth production. The right tools can save time, reduce waste, and improve precision.

Here are the main ones you should have:

Cutting order planning

Cutting order planning is essential for an organized workflow. It helps you decide the order in which to cut fabrics, based on priority and fabric types.

A well-planned order saves time and reduces mistakes. It ensures you cut the right fabrics first, minimizing delays and maximizing efficiency.

Learn more: The ultimate 6-step guide to choosing cutting plan software

Discarded fabric report

A discarded fabric report helps track the amount of fabric wasted during production. This tool gives you insight into where and why you discard fabric.

It helps identify patterns and areas for improvement. With accurate reports, you can make changes to reduce waste and save costs.

Piece identification and tracking

You must track each piece of fabric or garment from start to finish. This system helps you prevent losing pieces and ensures you account for every item. It improves accuracy and speeds up the production process.

With proper tracking, you can quickly address any issues in production.

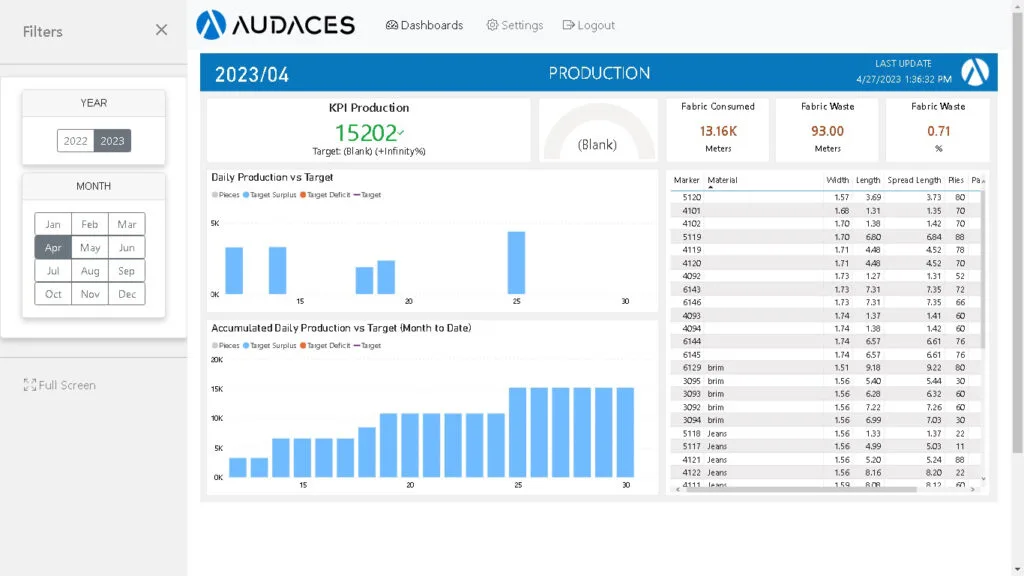

Real-time production indicators

Real-time production indicators give immediate feedback on production progress. These indicators show how well your production line is performing at any moment.

You can quickly spot slowdowns or bottlenecks and address them right away. This keeps the flow smooth and efficient.

Learn more: How to overcome slow cutting in your apparel manufacturing?

If you want to receive a free personalized project on how to automate your cutting room, fill in your email address below!

Benefits of using advanced industrial cutting tools

Advanced industrial cutting tools bring several key benefits to the manufacturing process. They improve efficiency, reduce waste, and ensure better-quality cuts.

Integration with other machines

When you connect your cutting tools to other equipment, they allow data to flow smoothly across the production line. This reduces errors and increases efficiency by ensuring every machine works together.

Instead of manually transferring data or materials, the system can automatically adjust to production needs.

Learn more: 4 reasons you should invest in a cutter room for fashion

Zero-gap cutting

Zero-gap cutting means that there is no space between pattern pieces during cutting. This results in a more efficient use of materials. With no gaps, you can maximize the amount of fabric used and minimize waste.

This technique also improves accuracy. Since you cut the fabric without space between the pattern pieces, you ensure they are more precise.

High cutting precision

High cutting precision reduces errors and ensures consistency in the final product. Precise cuts mean fewer mistakes during assembly, leading to higher-quality garments.

With high precision, manufacturers can also work with more complex designs. You can achieve fine details without sacrificing speed or material use.

Learn more: How can a good cutting plan transform your production?

Increased productivity

Increased productivity is one of the most significant benefits of advanced cutting tools. These tools cut faster and with greater precision, helping you produce more pieces in less time.

It leads to higher output with the same or fewer resources.

Scalability

As production needs increase, you can adjust industrial cutting tools to handle larger volumes of fabric or complex tasks.

It’s easier to expand operations without needing to invest in entirely new systems.

Scalable solutions also offer flexibility. Whether you need to adjust for a larger batch or a new design, they can accommodate changes without slowing down.

Learn more: Top 5 technologies driving mass customization in clothing

Discover Audaces industrial cutting tools!

See how we can help you improve product quality, optimize your processes, and increase profits.

Audaces Cutting Room

By embracing cutting-edge technology, garment manufacturers can achieve significant improvements in the production process. From greater design flexibility to enhanced efficiency and reduced costs.

This is where Audaces Cutting Room steps in! Our experts will thoroughly assess your company’s needs and create a comprehensive report.

Then, our team will develop a personalized project to achieve your goals and unlock your company’s full potential.

Rely on Audaces’ cutting-edge machinery to automate your production process. Achieve impeccable cuts on curves and details, speeding up your deliveries and minimizing fabric waste through automation.

Audaces ICF

An intelligent technology that connects people and cutting room equipment with high security.

It’s fully digital and focused on data security. It provides the best tools for planning and managing spreading and cutting processes.

In addition to streamlining your workflow, the online platform ensures access for all stakeholders. All information is available in real time via smartphone.

Managers can effortlessly schedule cut orders, specifying details like spreads, layers, cuts, and fabric quantities.

Moreover, Audaces ICF monitors and alerts about differences between planned and actual results, with automatic correction suggestions.

Was this article helpful? Get our latest content first by subscribing to the Audaces newsletter!

FAQ

These tools help streamline the cutting process, reducing the time spent on each garment. By automating parts of the production, you can cut down on labor costs and minimize human error.

Cutting order planning, discarded fabric report, piece tracking, and real-time production indicators.

Integration with other machines, zero-gap cutting, high cutting precision, and increased productivity.