Summary

- Automation is transforming fashion production by reducing manual tasks and increasing efficiency.

- It helps streamline workflows, improve quality, and ensure faster, more sustainable manufacturing.

- Want more insights into the fashion industry? Subscribe to our newsletter!

Behind every successful fashion collection, there’s more than creativity: there’s precision, timing, and technology working together. As competition intensifies, automation has become the key to keeping production fast, flexible, and profitable.

Let’s explore together the main types of automation shaping fashion manufacturing today, from intelligent cutting systems to integrated production management.

You’ll also understand how to choose the right solutions for your company’s needs and how they can drive real results.

Happy reading!

Sumário

How does automation work in the fashion industry?

Automation in the fashion industry uses technology to make production easier. It helps reduce the need for manual labor in repetitive tasks. With automated processes, companies can manage many tasks more easily. This allows human workers to focus on more important activities.

One of the key drivers of the types of automation is Artificial Intelligence (AI). These systems can analyze trends, forecast demand, and even assist in design, enabling more accurate decision-making.

By integrating AI into production workflows, fashion brands can respond more quickly to market changes and consumer preferences.

Probably the most significant benefit of automation is the reduction of repetitive processes. You can leave activities like cutting fabric or generating production reports for machines or AI-driven tools. This not only reduces human error but also improves consistency across all stages of production.

With these technologies in place, companies can achieve higher production without proportionally increasing costs or workforce size.

Automation allows for continuous operation, faster turnaround times, and more precise control over resources, helping brands scale their operations efficiently.

Most common types of automation in apparel manufacturing

Below are the main areas where automation is transforming apparel manufacturing:

Automation in design and pattern making

These types of automation help professionals test ideas quickly and produce accurate patterns without starting from scratch each time. They can generate multiple variations of a design, allowing teams to experiment while saving time.

Digital solutions now allow designers to simulate fabrics, fit, and garment construction in virtual 3D environments. It reduces manual changes and speeds up the workflow from concept to prototype.

Meanwhile, pattern makers are gaining consistency across different sizes and collections with the help of technology.

Learn more: How can fashion technology boost your production?

Automation in production planning

Scheduling, inventory tracking, and resource allocation are more efficient thanks to modern planning systems. Advanced software can simulate production timelines and adjust them to prevent bottlenecks.

These improvements enhance the manufacturing process, making it more coordinated and efficient while reducing delays and maximizing output.

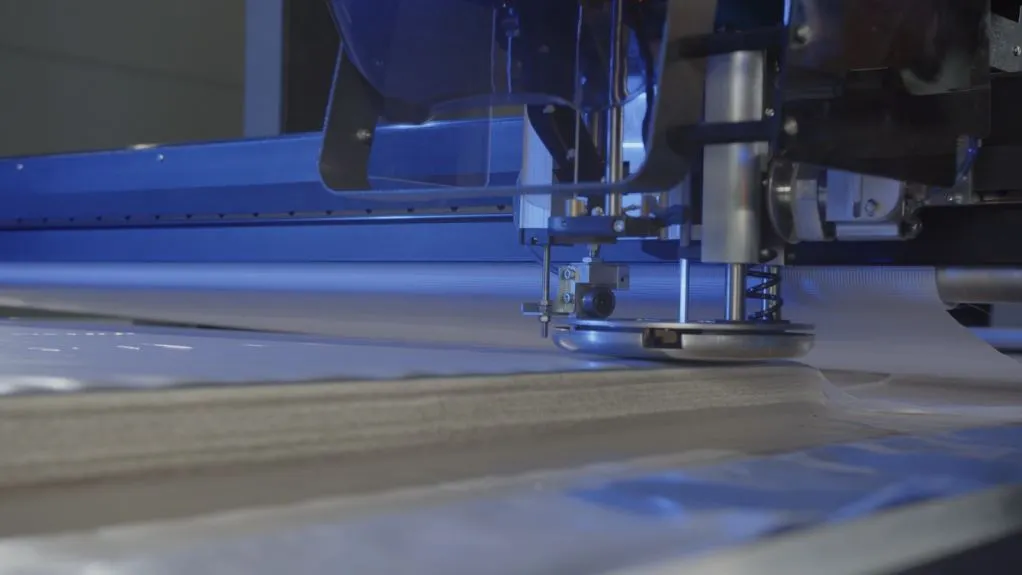

Automation in cutting

Cutting machines follow digital patterns with precision, reducing material waste and ensuring consistent results.

Factories often use an industrial automation system that combines high-tech cutting tools with software controls. This approach speeds up production while improving safety and frees workers from repetitive tasks.

Learn more: Learn why automation is key to optimize the cut process

Automation in sewing and finishing

Sewing and finishing processes can also benefit from automation. Machines can handle repetitive stitching tasks, embroidery, and button attachment with consistent precision, reducing errors and rework.

This type of automation helps maintain uniform quality across products. It ensures that each garment meets the same standards regardless of production volume. The result couldn’t be different: accelerated turnaround times and higher production rates.

Automation in quality control

Advanced cameras and sensors have the power to detect defects and inconsistencies faster than manual inspection. This combination provides repeatable, precise measurements and ensures garments meet quality standards.

It translates to consistent product quality, fewer returns, and increased customer satisfaction. All achieved with less time and effort.

Learn more: Find out how – and why – to apply textile automation in your company

Automation in logistics and shipping

Technology tracks inventory in real time, generates picking lists, and optimizes shipment routes, making operations more efficient. Many companies even use integrated automation systems to connect production with storage and delivery.

Automation in marketing and sales

Marketing and sales technology helps brands personalize customer interactions, generate product descriptions, and schedule campaigns. It allows teams to focus on strategy while machines handle repetitive communication tasks.

Automation tools like AI chatbots and content generators streamline workflows. The benefits include managing emails, generating promotional materials, and sales reports.

This way, companies can improve customer engagement, increase conversion rates, and deliver consistent messaging across all channels with ease.

Worried about implementing new technology in your production? Don’t be! Discover how to do it smoothly while keeping your operations running. Download our resource to learn more!

How can I choose the right type of automation?

Choosing the right automation starts with understanding your current processes and identifying where you are losing time or resources.

Every fashion business has different needs, depending on its size, production model, and market demands. That’s why evaluating your workflow carefully is the first essential step.

It’s also important to prioritize areas that directly impact cost efficiency or product quality. For instance, pattern development, cutting, and production planning are often the best places to start. This is because they influence the entire supply chain.

Next, consider scalability. Look for solutions that can grow with your company, integrating new technologies or expanding production capacity. This ensures your investment keeps paying off in the long term.

When all these factors come together, you can build a strong foundation for automated manufacturing that increases efficiency.

Learn more: Discover how Industry 5.0 is changing the fashion game

Benefits of automation for your fashion production

Automation offers more than just faster operations. It improves precision, consistency, and control across every step of the process. Below are the key advantages that make automation essential for the future of fashion production.

Increased productivity

When technology takes over time-consuming tasks, teams can focus on creative and strategic work. Automated systems ensure continuous operation without fatigue, increasing output significantly.

This efficiency also shortens lead times, allowing brands to produce and deliver collections more frequently throughout the year. As a result, companies can meet market demand faster while maintaining quality and consistency in every garment.

Reduced errors and rework

Manual processes are prone to mistakes, from pattern adjustments to cutting inconsistencies. Automation minimizes these risks by standardizing procedures and ensuring precise data use.

Because automation systems involve real-time monitoring, it detects any deviations and informs the operator immediately, preventing defective batches.

Material savings

Automated solutions optimize fabric usage by calculating the most efficient layout for cutting. This reduces leftover scraps and ensures that you use every roll of fabric to its full potential.

In addition, digital marking and smart cutting technologies also allow for quick adjustments when fabric widths or textures change.

Ultimately, better material management leads to lower costs and contributes to a more sustainable production model.

Learn more: Uncover the hidden key to successful fashion management

Consistent quality

Automation ensures that each garment follows the same specifications, regardless of who operates the machine. This uniformity eliminates variations in sewing, cutting, and finishing that often occur in manual workflows.

As a result, customers receive products that meet high-quality standards every time, strengthening the brand’s reputation.

Faster collection development

Technology reduces the time between concept and final product.

Automated design, pattern creation, and sampling processes speed up decision-making and approvals. Teams can simulate fits, test materials virtually, and make instant changes before cutting any fabric.

Smoother workflow between teams

Communication across departments often slows production. This is where the different types of automation come in, bridging these gaps by sharing data and updates in real time.

An automation system typically connects design, planning, and manufacturing, ensuring that everyone works with the same information. Integrating everything reduces miscommunication, improves coordination, and makes the entire process more transparent and efficient.

Learn more: The 4 most common myths about fashion AI you should know

Sustainability

Automating key production steps reduces waste, energy use, and unnecessary transportation. Each process becomes leaner and more eco-friendly. By using digital files, for example, companies cut down on fabric waste and emissions from shipping prototypes.

In short, automation supports sustainability by combining efficiency with environmental responsibility, a growing demand in the global fashion industry.

Higher profitability

With less waste, fewer errors, and faster deliveries, profit margins naturally increase. Companies can produce more with the same resources while maintaining quality.

Automation also improves cost control, making it easier to predict expenses and optimize investments in materials and labor.

This financial stability allows businesses to reinvest in innovation and growth, securing long-term success.

Automate your apparel production with Audaces technologies!

Follow the lead of Amibo, a Serbian brand known for its pajamas, underwear, and outdoor collections. The company started a digital transformation journey with Audaces to make its processes faster and more sustainable.

Discover how they did it!

Audaces360

Audaces360 integrates cutting-edge digital innovations to optimize workflows in the textile and apparel industry.

It caters to companies of all sizes and types, offering the flexibility to scale with your business needs.

All solutions were carefully developed to address the specific challenges of the field. They streamline the design and production processes, saving valuable time and resources.

The platform boasts a comprehensive range of functionalities, including pattern making, marking, collection management, vector drawing, and 3D creation.

In addition, a fashion Artificial Intelligence to assist you along the way.

Audaces Cutting Room

By embracing cutting-edge technology, garment manufacturers can achieve significant improvements in the production process. From greater design flexibility to enhanced efficiency and reduced costs.

This is where Audaces Cutting Room steps in. Our experts will thoroughly assess your company’s needs and create a comprehensive report.

Then, our team will develop a personalized project to achieve your goals and unlock your company’s full potential.

Rely on Audaces’ cutting-edge machinery to automate your production process. Achieve impeccable cuts on curves and details, speeding up your deliveries and minimizing fabric waste through automation.

Discover Audaces360 and unlock a world of possibilities for fashion design and production. Explore our comprehensive suite of solutions today!

FAQ

Automation in the fashion industry uses technology to make production easier. It helps reduce the need for manual labor in repetitive tasks.

The most common types of automation include design, pattern making, production planning, cutting, quality control, logistics, marketing, and sales.

The benefits include increased productivity, reduced errors, material savings, faster collection development, sustainability, and higher profitability.