Summary

- Industrial management focuses on improving efficiency. It helps reduce waste, save time, and increase output.

- For garment manufacturers, these benefits can make a big difference, whether you’re running a small or large company.

- Discover the complete solution for every stage of the fashion industry. Try Audaces360 for free today!

Running a garment manufacturing business can be challenging. From managing production lines to meeting customer demands, every step requires careful planning.

This is where industrial management comes in. It’s a set of tools and strategies to help your business work better.

Get ready to explore new ways to boost your success. Let’s make garment manufacturing simpler, smarter, and more effective.

Happy reading!

Sumário

Why is industrial management important for your garment manufacturing?

Industrial management is important for garment manufacturing because it helps streamline operations. It allows you to improve efficiency and reduce waste.

By organizing production processes, you can save time and resources, which leads to higher profits.

With industrial management, you can also ensure better quality control. It helps you maintain consistent standards in your products.

This is key to satisfying your customers and building a strong reputation in the market.

Learn more: Discover 4 essential points to thrive in clothing management

What is industrial management?

Industrial management is the process of overseeing and improving production systems. It involves planning, organizing, and controlling resources to produce goods efficiently.

The goal is to maximize productivity while minimizing costs.

In garment manufacturing, industrial management covers everything from raw material procurement to final product delivery.

It helps manage the flow of materials, labor, machinery, and the entire supply chain. This ensures that production runs smoothly and meets deadlines.

Industrial management also focuses on continuous improvement. It looks for ways to enhance processes and solve problems.

Learn more: How to perform effective supplier management in fashion

What are the pillars of industrial management?

Production planning and control

Production planning and control ensure that manufacturing runs smoothly. It involves scheduling tasks, managing resources, and tracking progress.

The focus is on meeting production targets on time. It also helps identify any delays or issues early.

Problem-solving is a key part of production planning. When problems arise, like machine breakdowns or material shortages, production planning helps find quick solutions.

This keeps production on track and reduces downtime.

Quality management

Quality management ensures that products meet set standards. It focuses on preventing defects and improving product consistency.

By monitoring each stage of production, businesses can identify and fix quality issues early.

This system also helps build customer trust. When customers receive high-quality products, they are more likely to return.

Learn more: How can technology enhance the quality of textile products?

Process control

Process control is about monitoring and adjusting production processes. It helps maintain consistency in output and reduces variations.

By controlling the process, manufacturers can produce high-quality products every time.

It’s crucial in the product development process, where precision is key to turning design ideas into finished products.

A collection manager plays an important role in this process. They oversee the entire development of a collection, ensuring that each stage aligns with the original design.

Learn more: 6 benefits of having online collection management

Preventive maintenance

Preventive maintenance helps avoid equipment breakdowns. It involves regular checks and repairs to keep machinery in good condition.

By fixing problems before they happen, you can prevent costly repairs and downtime.

Audaces’ commitment to your success includes providing preventive maintenance for all Audaces equipment.

Our skilled team is here to ensure your machinery operates at peak performance for years to come.

Learn more: Discover the importance of textile equipment maintenance

Logistics and inventory management

Logistics and inventory management ensure that materials are available when needed. It involves tracking stock levels, ordering materials, and managing delivery schedules.

Having the right materials on hand at the right time avoids overstocking and shortages. This ensures smooth and cost-effective operations.

Learn more: Discover 8 best practices for optimizing apparel inventory management

Technological automation

Technological automation uses machines and software to improve production. It speeds up tasks, reduces human error, and lowers costs.

Automation can handle repetitive tasks, allowing workers to focus on more complex jobs.

Technology also improves accuracy. With automated systems, businesses can ensure that all products follow precise specifications.

As experts in fashion manufacturing, we’ve created an essential resource just for you. The best part? It’s free! Download our guide now to boost your company’s productivity.

Who is responsible for industrial management in garment manufacturing?

In garment manufacturing, industrial management is typically the responsibility of managers and supervisors.

They oversee the entire production process, ensuring that operations run smoothly. Moreover, these leaders coordinate resources, schedule tasks, and monitor progress.

It’s important to highlight that collaboration between various departments is essential for effective industrial management.

How can you implement effective industrial management in your garment manufacturing?

Analyze the current production flow

It’s the first step to improving industrial management. It involves reviewing how materials, labor, and machinery move through each stage of production.

Once you map out the flow, spot areas for improvement. For example, if certain processes take longer than expected, you can work on adjustments.

This analysis helps ensure that production stays on track and meets deadlines.

Evaluate available resources

It includes assessing both labor and machinery. Understanding the capabilities and limitations of your workforce and equipment helps you allocate resources effectively.

This way, you can determine if you need additional workers or upgraded machinery. It also helps identify any gaps in skills or equipment that could slow down production.

Define performance indicators

These indicators track how well production is meeting goals. Examples include production speed, quality levels, and resource usage.

Regularly reviewing these indicators helps guarantee that production stays on track and that any issues are addressed quickly.

Plan and control production

Planning and controlling production are at the heart of industrial management. It involves creating a production schedule, allocating resources, and monitoring progress.

It also means making adjustments when necessary. If there are delays or inefficiencies, you can propose changes to get back on track.

Optimize factory layout

A well-organized layout reduces unnecessary movement of materials and workers. This improves efficiency and reduces production time.

The right layout can minimize bottlenecks and help production run smoothly.

Train employees

As technology evolves, it’s important that workers are equipped with the necessary skills. By providing ongoing training, you ensure that your team stays up to date with the latest tools.

This increases productivity and helps avoid mistakes caused by a lack of knowledge.

Conduct regular audits

Audits help assess the efficiency of production processes, resource usage, and product quality. Review operations regularly, so you can spot problems before they become bigger issues.

It also helps ensure that all processes are in compliance with industry standards. They provide valuable insights to identify areas for improvement.

What are the benefits of implementing industrial management?

Implementing industrial management principles in garment manufacturing brings a range of significant benefits:

- Streamlined processes

- Improved resource use

- Consistent quality

- Reduced rework

- Efficient inventory management

- Increased adaptability to market changes

- Performance monitoring

- Continuous improvement

How does technology assist in industrial management?

Technology allows for automating tasks and improving efficiency. This reduces the need for manual work, speeds up processes, and increases precision.

It also provides real-time information about production performance, which helps managers make informed decisions.

By using technology, businesses can identify problems quickly and implement solutions, leading to smoother operations and better results.

Implement industrial management with Audaces solutions

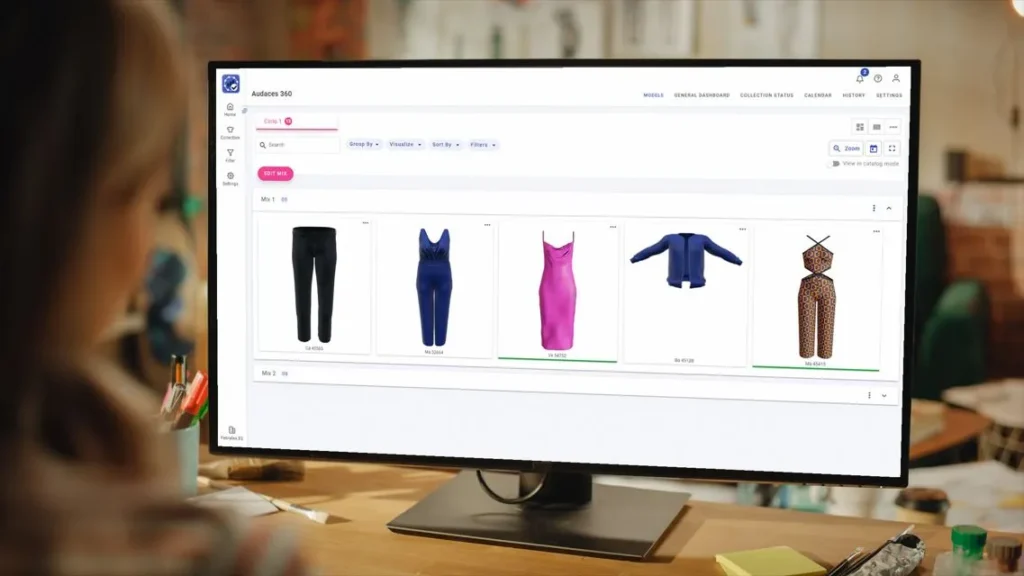

Audaces360

Audaces360 integrates cutting-edge innovations to optimize workflows in the textile and apparel industry.

It caters to companies of all sizes and types, offering the flexibility to scale with your business needs.

All solutions were carefully developed to address the specific challenges of the market. They streamline the design and production processes, saving valuable time and resources.

The platform boasts a comprehensive range of functionalities, including pattern making, marking, collection management, vector drawing, and 3D creation.

In addition, a fashion Artificial Intelligence to assist you along the way.

Audaces Cutting Room

By embracing cutting-edge technology, garment manufacturers can achieve significant improvements in the production process. From greater design flexibility to enhanced efficiency and reduced costs.

This is where Audaces Cutting Room steps in! Our experts will thoroughly assess your company’s needs and create a comprehensive report.

Then, our team will develop a personalized project to achieve your goals and unlock your company’s full potential.

Rely on Audaces’ cutting-edge machinery to automate your production process. Achieve impeccable cuts on curves and details, speeding up your deliveries and minimizing fabric waste through automation.

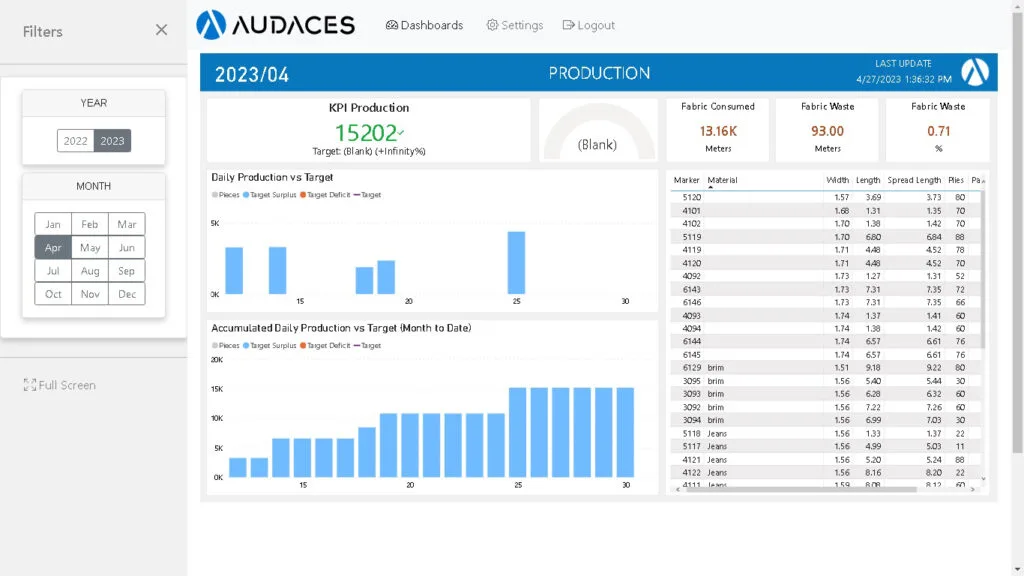

Audaces ICF

An intelligent technology that connects people and cutting room equipment with high security.

It’s fully digital and focused on data security. It provides the best tools for planning and managing spreading and cutting processes.

In addition to streamlining your workflow, the online platform ensures access for all stakeholders. All information is available in real time via smartphone.

Managers can effortlessly schedule cut orders, specifying details like spreads, layers, cuts, and fabric quantities.

Moreover, Audaces ICF monitors and alerts about differences between planned and actual results, with automatic correction suggestions.

Was this article helpful? Get our latest content first by subscribing to the Audaces newsletter!

FAQ

Industrial management is important for garment manufacturing because it helps streamline operations. It allows you to improve efficiency and reduce waste.

Industrial management is the process of overseeing and improving production systems. It involves planning, organizing, and controlling resources to produce goods efficiently.

Production planning and control, quality management, process control, preventive maintenance, logistics and inventory management, and technological automation.