Summary

- Understand the importance of textile quality control in ensuring consistency and reducing production waste.

- Explore the tools and technologies that help monitor and improve textile quality throughout production.

- Want to take your company further? Subscribe to our newsletter for exclusive insights!

Textile quality control is one of the pillars of efficient and reliable production. It ensures that every fabric, thread, and finished garment meets the expected standards before reaching the customer.

But how can you apply it effectively in practice? Today, technology plays a key role in improving this process. Modern solutions automate inspections, store data for traceability, and monitor quality requirements in real time.

In the next sections, we’ll see the benefits of quality control, how to perform it efficiently, and which digital tools can help you.

Happy reading!

Sumário

What is textile quality control and why is it important?

Textile quality control is the process of monitoring every stage of production to ensure that products meet specifications. It starts with raw materials and extends through weaving, dyeing, finishing, and garment assembly.

In garment manufacturing, high quality is not just about appearance but also about performance.

Fabrics must meet expectations for durability, color fastness, and comfort, among other criteria. Constant checking ensures that these aspects are consistent, regardless of production volume or time constraints.

For production managers, applying quality control means transforming data and inspection results into actionable improvements. This process allows better decision-making and helps maintain harmony between productivity goals and product excellence.

What are the benefits of textile quality control?

The process delivers a wide range of benefits for manufacturers and consumers. It supports compliance with quality standards, prevents production failures, and ensures customer satisfaction.

A well-implemented control process also reduces waste, increases operational efficiency, and promotes a culture of continuous improvement within the company.

Check out the key benefits:

Keeps consumers safe and satisfied

With quality control, you can guarantee that textiles are free from defects or harmful substances that could cause irritation.

This is especially critical in segments such as children’s wear, medical fabrics, and sports apparel. Safety requirements in these areas are strict and non-compliance can lead to serious consequences.

Beyond safety, quality control ensures that consumers receive products that perform as promised. A well-made garment maintains its shape, color, and comfort even after several washes.

Detects and prevents errors

By inspecting samples regularly, production teams can spot issues before they affect the entire batch. They can include color variation, fabric defects, or sewing problems

Early detection not only prevents large-scale rework but also saves valuable time and materials in the textile industry.

Read more: How can technology enhance the quality of textile products?

Ensures product consistency

Quality control ensures that every roll of fabric or finished product looks the same. Regardless of when or where you produced it.

Consistency is what makes a brand recognizable and dependable in the eyes of customers.

Read more: How to obtain quality and precision in the cutting fabric process?

Promotes continuous improvement

When we talk about quality control, it’s important to notice that it’s not just about finding faults. It’s about learning from them. Each inspection and analysis provides valuable insights into where you can improve the process.

Over time, these adjustments build a stronger and more efficient production system.

With proper performance indicators, you can identify recurring issues and address their root causes. This ongoing evaluation drives innovation and fosters a mindset focused on progress and excellence.

Ready to take your production to the next level? This fashion e-book holds powerful insights! Download it now and unlock new growth opportunities.

How to perform textile quality control after production?

Once production ends, quality control procedures remain essential. They ensure the final product meets the company’s standards and customer expectations.

Garment quality control verifies whether the products align with design requirements, measurements, and overall appearance. It not only confirms the consistency of the process but also provides insights for improvements in the future.

Here’s how you can do it:

Analyze production processes

The first step in post-production is to carefully review every stage of the manufacturing process. This includes checking whether raw materials, machines, and labor operated according to the established specifications.

Process analysis also helps detect patterns of inefficiency in the production line.

For example, if fabric shrinkage or color inconsistency appears frequently, it may indicate an issue in sourcing or finishing.

Read more: Learn what textile processing is and how it adds value to your production

Define the tools you’ll use

Using the right tools is essential for a precise and efficient quality control system.

Inspection equipment, measurement instruments, and testing devices should align with the type of textile product you have. Depending on the product, tools may include fabric inspection machines, color assessment cabinets, and tensile strength testers.

In addition to physical tools, digital solutions play a growing role in managing inspections and traceability.

Software designed for production management allows teams to record test results, compare them with standards, and generate detailed reports.

Correct detected failures

When you find failures during inspection, the response must be quick and precise.

Correcting them involves identifying the cause, if they are isolated or systemic, and defining a way to fix them. This could include reworking a batch, adjusting machine settings, or retraining employees to prevent similar mistakes in the future.

Read more: 4 key steps to streamline your fashion production process

Monitor customer satisfaction

Post-production quality control doesn’t end when the products leave the factory. Monitoring customer satisfaction is crucial for evaluating how well your products perform in real-world conditions.

Feedback from clients, retailers, and end users helps identify potential weaknesses that internal inspections may have missed. This ongoing dialogue with the market provides valuable data for product development and helps reinforce long-term brand loyalty.

Ultimately, quality control becomes a vital part of the company’s commitment to excellence and trust.

How is textile quality control in practice?

Random or individual sampling

Instead of checking every single item, you can use random or individual methods to evaluate portions of a batch.

Random sampling helps detect variations across production lots. Meanwhile, individual sampling is ideal for products that require a higher level of precision or customization.

Choosing the right sampling strategy depends on the type of textile and the customer’s requirements.

For mass-produced fabrics, random sampling is often sufficient to guarantee uniformity. However, for high-end garments, individual inspection ensures that every piece meets the brand’s standards before delivery.

Read more: Learn how to improve production and productivity in fashion

Technical specifications

They define the exact requirements each product must meet. It could include fiber composition, weight, color fastness, shrinkage tolerance, and tensile strength.

To apply these standards effectively, production teams must use objective measurement tools and reference samples.

Comparing real production outcomes against technical benchmarks allows for quick detection of deviations and helps maintain consistency across different manufacturing cycles.

On-site inspection

This is where quality control happens in real time. Inspectors evaluate products on the production floor, ensuring they meet the standards before materials move to the next stage.

The immediate feedback allows for quick adjustments, preventing issues from spreading through the production line.

During on-site inspections, professionals check a variety of factors. They include fabric appearance, color uniformity, sewing precision, and overall finishing. Depending on the production setup, these inspections can occur at different checkpoints, from weaving and dyeing to final packaging.

Read more: 6 key benefits of adopting a continuous production model

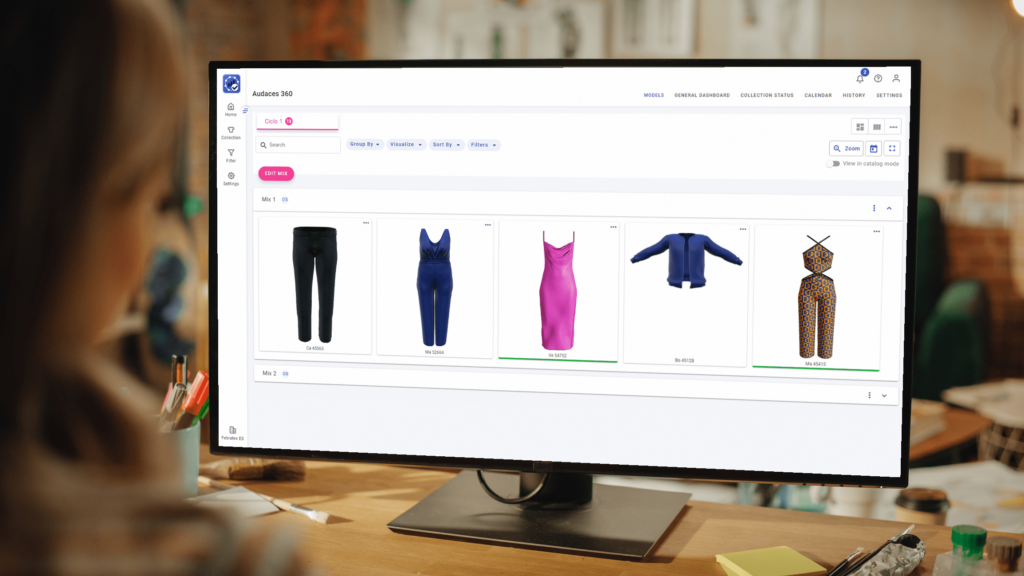

Boost efficiency of textile quality control in your company with Audaces360

Audaces Isa

Streamline your workflow, accelerate production, and elevate your brand with Audaces Isa.

This innovative solution empowers fashion companies to take control of their entire collection development process. It centralizes data and fosters collaboration, leading to more than a 30% reduction in product launch time.

You can even have real-time access to your collection progress directly from your phone, with the mobile version.

Identify potential issues early, track progress seamlessly, and enable teams to optimize production and quality.

Audaces Marker

Audaces Marker is the best solution to create a marker for cutting fabric with perfection. We used cutting-edge technology so you can improve the efficiency of your production process.

With this powerful ally, companies can lay out patterns in a way that reduces waste and makes the most of their raw materials.

It allows professionals to create markers more efficiently, saving time and money.

Discover Audaces360 and unlock a world of possibilities for fashion management. Explore our comprehensive suite of solutions today!

FAQ

Textile quality control is the process of monitoring every stage of production to ensure that products meet specifications. It starts with raw materials and extends through weaving, dyeing, finishing, and garment assembly.

It keeps consumers safe and satisfied, detects and prevents errors, ensures product consistency, and promotes continuous improvement.

Methods include random or individual sampling, technical specifications, and on-site inspection.