Summary

- Whether you’re working in a small workshop or a large-scale factory, understanding markers is key.

- With the right knowledge, you can optimize your fabric cutting to reduce costs and enhance garment quality.

- Experience the future of fashion technology with Audaces360 solutions. Start your free trial today!

Creating a marker for fabric cutting is a key step in the garment-making process. It affects fabric usage, cutting efficiency, and production quality.

A well-planned marker layout can save time, reduce waste, and improve the fit of each piece. That’s why we’ll explore the basics of how to create a marker.

We’ll touch on the main techniques and tools used, helping you understand how to maximize efficiency and accuracy.

Happy reading!

Sumário

Why create a marker before cutting the pieces in your production?

Creating a marker ensures you use the fabric efficiently, minimizing waste and saving costs. This step is especially important for larger productions, where even small amounts of waste can add up.

Markers also help maintain consistency in each piece cut. When you arrange pieces carefully, the result is a precise cut for each garment part.

This consistency improves the fit and look of your final product. It also reduces errors, as you follow a clear, pre-planned layout.

Learn more: 4 reasons to create automatic marker on the computer

How to create a marker with no fabric waste?

Reducing fabric waste starts with good planning. When you create a marker with precision, you can cut efficiently and save costs.

Understand the fabric features

Before you create a marker, it’s important to know each fabric’s features. Materials vary in stretch, weight, and texture, which affect the arrangement of patterns.

Some fabrics, like knits, may need patterns in a specific direction to prevent distortion. Knowing these details helps you create a marker that avoids waste while maintaining quality.

Also, consider the fabric width and any patterns or prints. Aligning patterns according to fabric width maximizes the usage.

For fabrics with specific prints, ensure each piece lines up correctly to avoid issues during sewing.

Learn more: Complete guide to fabric creation for your apparel business

Use good marker software

Marker software can simplify the process and save you time. Good software helps you arrange pieces in a way that reduces waste and improves accuracy.

It also automates many steps, so you can quickly create a marker.

Most marker software offers different settings for arranging pieces. With a few clicks, you can set up options for piece rotation, spacing, and alignment.

Another benefit is that this solution provides estimates on fabric usage. You can adjust your layout and see how much fabric you’ll save, making it easier to plan costs and reduce waste.

Learn more: 5 benefits of using technology as a partner in cut and sew

Test different automatic marker setups

Many marker software tools offer automatic setups that arrange pieces for you. Testing these options can show you the most efficient layout for your fabric.

Automatic setups often optimize for fabric width and pattern size, which helps avoid gaps.

With different setups, you can compare how each affects fabric use. Some setups may be more efficient than others, depending on your fabric and pattern shapes.

Trying multiple setups helps you find the best match for each order. As you test, you’ll learn which settings save the most fabric, helping you make smarter choices.

Learn more: How can mass production boost your apparel manufacturing?

Group similar patterns

Grouping similar patterns can reduce fabric waste. When you place patterns with similar shapes together, they fit more tightly, filling gaps.

This technique to create a marker is especially useful for items with similar dimensions or shapes.

For example, group patterns for sleeves or pockets together. Smaller pieces can often fill spaces left by larger ones, reducing gaps.

Using groups also makes the cutting process easier and more organized. You’ll be able to cut similar items in one section, which can speed up production.

Ready to optimize your fabric usage? Our complete e-book will teach you how to create efficient markers, saving you time and money. Download for free now!

Sort patterns by size

Sorting patterns by size can also help reduce waste. Place larger patterns first, as they need more space, and then fit smaller ones around them.

The strategy ensures that bigger pieces have the room they need without wasting space.

Once larger patterns are in place, you’ll likely have small gaps left. This is where smaller patterns come in. By adding them to these spaces, you minimize waste and make full use of the fabric.

Sorting by size also helps create a balanced marker. Each piece has an optimal position, reducing the risk of shifting and making cutting easier.

Learn more: Why should your company invest in fabrication technology?

Rotate pieces, if necessary

Sometimes, rotating pieces can save fabric. Certain shapes fit better in tight spaces when you rotate them, filling areas that would otherwise go unused.

Check if your fabric allows rotation without affecting the final garment. If it has no strict grain requirements, try rotating pieces by 90 or 180 degrees.

You might find a better fit that reduces gaps. This technique is useful for pieces like facings or linings, which may have more flexibility.

But remember to check each rotation before cutting. Certain fabrics can stretch or distort, so test carefully to ensure the quality of your garment.

Learn more: How to set up a plotter room for your fashion business?

Generate usage reports

The best marker solutions can generate usage reports, giving you insight into fabric efficiency. These reports show how much fabric each marker layout uses.

Reviewing them helps you identify areas for improvement. They also allow you to compare different layouts.

By seeing which one uses less fabric, you can make adjustments and improve over time. These insights make it easier to track costs and avoid waste.

Finally, reports can highlight trends across projects. Over time, you’ll gain a clearer picture of what works best for specific fabrics and patterns. It helps you refine your process for future projects.

Benefits of creating a marker with perfect patterns

Creating a marker with perfect patterns helps save time and resources. It also improves the quality of the final product.

In this way, companies can make better use of their materials and increase efficiency. Check out the main benefits:

Reduced raw materials

When the pattern is perfect, the result is less material waste. You can cut the pieces with more precision, leaving fewer scraps behind.

This means companies can use less raw materials to make the same number of items. The costs go down and the production process becomes more sustainable.

Companies save money by reducing waste, which they can use for other improvements. It leads to a more efficient use of resources, making production more eco-friendly.

This contributes to reducing the fashion industry’s environmental impact, which is under fire for its wasteful practices.

Increased productivity

Perfect patterns allow machines to work faster and more accurately. With a better layout, you need less adjustments during the cutting process.

This leads to fewer delays and more items produced in less time. The smoother production process helps workers stay focused on their tasks, boosting productivity.

By saving time, companies can increase output, leading to higher profits and greater customer satisfaction.

In the long run, this efficiency makes businesses more competitive in the market.

Learn more: 5 strategies to optimize your production with efficient fashion

Guaranteed quality of pieces

With a perfect pattern, you can cut each piece with high precision. This ensures that all items are uniform and meet the required quality standards.

Consistent quality reduces the risk of defects or errors in the final product. When every piece is accurate, the finished product is more durable and reliable.

This not only satisfies customers but also helps maintain the reputation of the brand.

By using perfect patterns to create a marker, companies guarantee that each item is of the highest quality.

Create automated markers with the best of Audaces technology

Audaces Marker

Audaces Marker is the best solution to create a marker for cutting fabric with perfection. We used the best of technology to design it to improve the efficiency of the production process.

With this powerful ally, companies can lay out patterns in a way that reduces waste and makes the most of their raw materials.

It allows professionals to create markers more efficiently, saving both time and money.

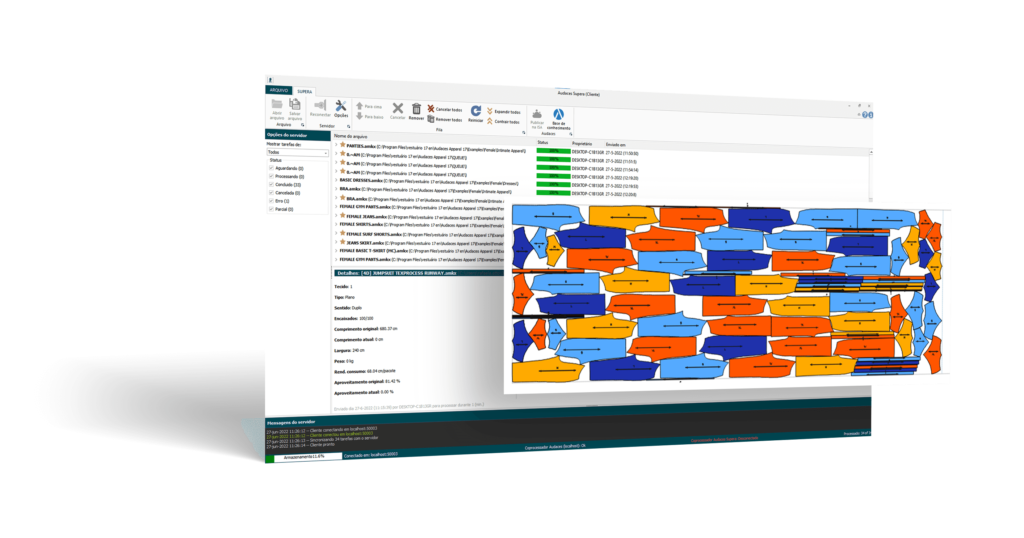

Audaces Supera Max

Audaces Supera Max is a server capable of managing queues and ordering various markers for automatic calculation.

Reduce fabric waste even further, keeping your workstation free to prepare the next marker.

Our technology uses smart algorithms to arrange patterns on fabric in the most efficient way possible.

Want to stay up to date on the latest fashion industry news? Subscribe to our newsletter!

FAQ

Creating a marker ensures you use the fabric efficiently, minimizing waste and saving costs. This step is especially important for larger productions, where even small amounts of waste can add up.

Understand the fabric features, use good marker software, test different automatic marker setups, group similar patterns, sort patterns by size, rotate pieces when necessary, and generate usage reports.

Reduced raw materials, increased productivity, and guaranteed quality of pieces.