Summary

- In a competitive market like fashion, production capacity is the key to success.

- You can produce more with less effort using the right tools. That’s the power of technology!

- Experience the future of the fashion industry with Audaces360. Sign up for your free trial today.

In the world of fashion manufacturing, staying ahead means producing more in less time—without compromising quality. That’s where increasing your production capacity becomes essential.

But how can you make that happen? The answer is not just about working harder. It’s actually about working smarter.

Optimizing workflows, using the right tools, and making small but impactful changes can lead to impressive results. So, dive in and explore strategies that could transform your business.

Happy reading!

Sumário

Why is it important to calculate your production capacity?

Calculating your production capacity helps you understand how much you can produce within a specific amount of time. It allows for smarter planning and scheduling.

Without this knowledge, you risk overloading your team or underusing resources, leading to delays or wasted potential.

By knowing your limits, you can improve overall equipment effectiveness (OEE). This helps you use machines and workers to their best. It means fewer breakdowns, less downtime, and smoother operations on the shop floor.

It also helps in managing both short-term and long-term goals. In the short term, it enables quick adjustments to meet sudden increases in demand.

In the long term, it supports strategic decisions like expanding capacity or investing in new technologies.

Learn more: What is the fashion industry, its value, and key players?

What is the production capacity in a clothing factory?

Production capacity refers to the maximum number of garments a company can produce within a specific period. It depends on available resources like machinery, labor, and working hours.

Effective capacity planning ensures that production aligns with demand. It helps factories avoid overloading or underusing resources, leading to a balanced workflow and reduced costs.

A factory reaches full capacity when it fully optimizes all resources, ensuring that no delays or quality issues arise.

However, consistently operating at full capacity can strain equipment and staff, so careful planning is paramount.

Manufacturing processes also influence production capacity. Complex designs or special techniques can slow down production, while streamlined processes increase efficiency.

Balancing these factors ensures consistent output without sacrificing quality.

Factories that produce multiple products face additional challenges in capacity management. Different styles and fabrics may require varied production times.

To sum it up: proper planning helps handle these variations smoothly, maintaining productivity and meeting market demands.

Learn more: How can mass production boost your apparel manufacturing?

Benefits of understanding your company’s production capacity

More assertive decision-making

Understanding your company’s production capacity enables better decision-making. With a clear view of how much you can produce, you can plan more accurately.

This insight allows you to set realistic goals and timelines for deliveries. It also helps in optimizing resource allocation, ensuring that you avoid bottlenecks and delays.

By using data, like production planning and key metrics, decisions become more informed and targeted. The result is more effective strategies and improved performance.

Reduced waste and errors

Knowing your production capacity helps minimize waste and errors. It ensures efficient use of resources, such as fabrics and materials.

With clear capacity limits, you can avoid excess production and stockpiling unnecessary goods.

Additionally, a deeper understanding of your production limits allows for precise forecasting, reducing mistakes and rework.

This reduces fabric cuts and prevents producing the wrong sizes. Ultimately, it helps streamline operations, lowering costs and enhancing quality control.

Learn more: What is industrial quality control in the textile business and how does it work?

Increased employee productivity

When employees know the expected production capacity, they can work more efficiently. Accurate knowledge of production capacity in each work shift helps set achievable targets more easily.

It leads to better planning of production lines and smoother workflows. Employees can focus on meeting their set goals rather than facing uncertainty.

This improved clarity increases productivity, as everyone works towards the same objectives with a clear understanding of their roles.

Take action now to boost your apparel manufacturing efficiency! Download our free guide and discover exclusive professional tips.

How to boost your production capacity?

To boost your production capacity, it’s important to focus on both short-term and long-term strategies. With the right approach, you can optimize your processes, improve efficiency, and increase output.

There are several areas to focus on that will have a direct impact on how much your factory can produce.

Automate your processes

Automation is one of the most effective ways to increase production capacity in clothing manufacturing.

By automating repetitive tasks, you can speed up your processes and reduce human error. This helps to increase the overall output while maintaining consistency and precision.

Automation solutions can manage everything from fabric cutting to stitching, ensuring the efficient performance of each task.

Integrating real-time data into your automated systems can further enhance productivity.

With instant updates on inventory, production progress, and machine status, you can make more informed decisions quickly.

This level of insight helps identify areas where you can expand or optimize automation for better results.

Automation also reduces the need for manual labor, allowing employees to focus on more complex tasks. It helps improve workflow, speed up production, and reduce bottlenecks in the process.

Moreover, automated systems are scalable. As your production needs grow, you can easily expand your automation to keep pace with demand.

It’s easier to maintain consistent output without overloading your team or machinery.

Learn more: How can technology enhance the quality of textile products?

Train your team

When employees are well-trained, they perform tasks more efficiently and accurately. Training helps workers understand their roles better, which leads to fewer mistakes and faster completion of tasks.

With the right knowledge, employees can make decisions that support production goals and improve the flow of work.

Proper training also helps with problem-solving. When challenges arise on the production floor, a skilled team can quickly identify the issue and find a solution.

This reduces downtime and keeps production running smoothly. It also boosts confidence, as employees feel more competent in handling various tasks and situations.

Additionally, providing ongoing training ensures that your team keeps up with industry changes. New techniques, machinery, and software can improve efficiency, and your team needs to be familiar with these updates.

Continuous learning keeps your workforce engaged and invested in the company’s success.

When you make team training a priority, you’re helping create a more positive work environment. This, in turn, helps boost your production capacity.

Learn more: Boost your garment manufacturing with industrial management

Implement new technologies

New technologies are constantly emerging that can improve the efficiency of your production processes. And implementing these innovations can significantly boost your production capacity.

From automated cutting machines to software to managing collections, new technologies make manufacturing faster and more precise.

Lean manufacturing techniques, when integrated with the right technology, can help you streamline processes and eliminate waste.

Technologies that track and analyze data allow you to identify inefficiencies and make improvements quickly.

By constantly optimizing workflows, you can increase your factory’s output without adding more resources.

The use of modern tools also improves product quality. With automated systems, you can reduce human error, ensuring more consistent results.

This reduces the need for rework and repairs, allowing you to allocate resources to other areas of production.

The more you integrate technology into your processes, the smoother the operation becomes. It may require an initial investment, but the long-term benefits far outweigh the cost.

Learn more: Discover how can technology revolutionize menswear production

Perform regular maintenance

Machines and equipment wear down over time, which can slow down your production process.

By performing routine checks and maintenance, you can prevent breakdowns and ensure your equipment runs smoothly.

Using a production capacity formula, you can pinpoint areas where maintenance is most needed. This allows you to focus on the equipment that is most critical to maintaining a steady production flow.

Moreover, regular servicing reduces the likelihood of unexpected downtime, keeping your production lines running efficiently.

Scheduled maintenance also extends the lifespan of your equipment. By addressing issues before they become major problems, you protect your investment in machinery.

This helps your factory operate at full capacity for longer periods, maximizing the return on your equipment.

Increase your production capacity with Audaces solutions

See how we can help you improve product quality, optimize your processes, and increase profits.

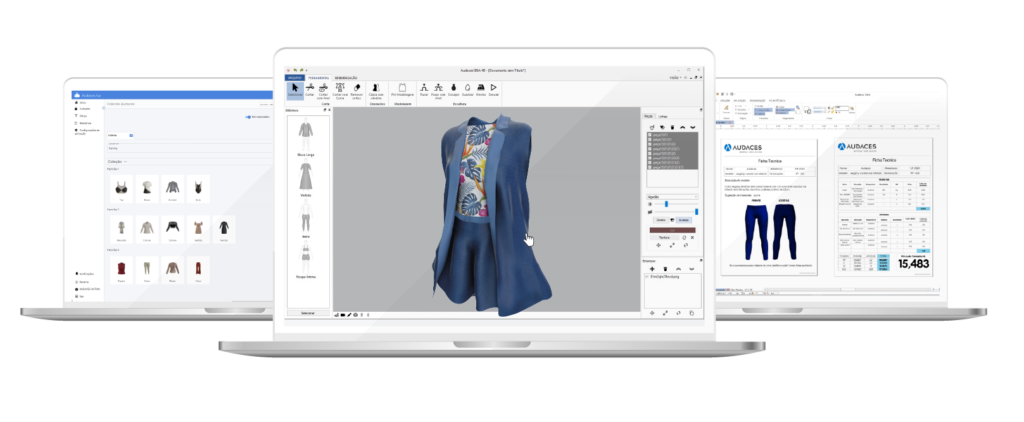

Audaces360

Audaces360 integrates cutting-edge digital innovations to optimize workflows in the textile and apparel industry.

It caters to companies of all sizes and types, offering the flexibility to scale with your business needs.

All solutions were carefully developed to address the specific challenges of the field. They streamline the design and production processes, saving valuable time and resources.

The platform boasts a comprehensive range of functionalities, including pattern making, marking, collection management, vector drawing, and 3D creation.

In addition, a fashion Artificial Intelligence to assist you along the way.

Audaces Cutting Room

The innovation promoted by Audaces Cutting Room does not simply come from new technologies. It’s the result of practical monitoring of our customers’ daily production.

This is how we developed the integrated software and hardware solution that empowers manufacturers to improve their processes.

Rely on Audaces’ cutting-edge machinery to automate your production workflow. Achieve impeccable cuts on curves and details, speeding up your deliveries and minimizing fabric waste.

Our team will develop a personalized project to achieve your goals and unlock your company’s full potential.

We offer everything from production monitoring software to the latest spreading and cutting machines for maximum efficiency.

Discover Audaces360 and unlock a world of possibilities for apparel manufacturing. Explore our comprehensive suite of solutions today!

FAQ

Calculating your production capacity helps you understand how much you can produce within a specific amount of time. It allows for smarter planning and scheduling.

Production capacity refers to the maximum number of garments a company can produce within a specific period. It depends on available resources like machinery, labor, and working hours.

More assertive decision-making, reduced waste and errors, and increased employee productivity.