Summary?

- Innovating means envisioning and introducing new modes of design and production, which is crucial in a dynamic sector like fashion;

- Certain trends are already emerging, defining the main areas of innovation for the future;

- To incorporate fashion innovation into your company, experience the multi-solution Audaces360! Download the free trial now.

Innovation is a powerful driver of change, playing a vital role in bringing creativity and efficiency to the fashion sector.

The components of innovation encompass various dimensions, including trend analysis, technological advancements, sales and consumption models, organizational processes, and even personal attitudes.

If you are interested in gaining a better understanding of the concept of fashion innovation and learning how to implement it effectively in your company, this article is a must-read for you.

We hope you find it useful!

Sumário

What does fashion innovation mean?

Innovation is a crucial element that enables businesses to attain greater opportunities for success and stand out in a competitive landscape.

It is a quality we expect from both our personal and professional lives, although its urgency and expression can vary across different sectors.

Within the textile and fashion industry, innovation has played a central role in shaping the course of human history.

The sector’s evolution has been intertwined with significant economic and industrial revolutions, influencing various aspects of society, including production processes, cultural shifts, and social interactions.

In fashion, innovation can encompass product enhancements, the establishment of new customer relationships, and the reevaluation of production methods.

In this highly sought-after market, characterized by ever-changing trends, rapid-paced dynamics, and the constant need to engage customers, innovation is a fundamental requirement. It motivates customers to make purchases and drives the industry forward.

7 trends shaping fashion innovation

In the fashion world, several trends are making a significant impact on the industry and are likely to shape innovation research in the coming decade.

Let’s see some of them:

1. Sustainability

Sustainability is a crucial challenge that the fashion industry faces.

Many fashion companies are embracing new technologies and transitioning towards a more sustainable and circular business model.

From design and material choices to production processes and product recycling, sustainability has become a fundamental imperative for the industry.

It requires a multidisciplinary approach focused on innovation and the development of new professional practices.

Learn more: Why consider sustainable consumption and production for your company?

2. Blockchain

Blockchain technology is already making waves in the market and is expected to further develop and expand its implementation.

It allows consumers to trace the entire production cycle of a garment, from design to sale, ensuring transparency and traceability.

This is particularly important as consumer purchasing choices are increasingly influenced by environmental and social sustainability criteria.

3. Augmented reality

Augmented reality seamlessly integrates the physical fashion experience with the digital world, creating fully simulated images and spaces.

It offers a powerful consumer tool, enabling clothing virtual fitting rooms, reducing the number of returned items, and minimizing textile waste generated from overproduction.

4. Metaverse

The metaverse is a virtual environment where people can interact with digital objects in real time.

It is expected to gain more prominence in the future, especially considering that research shows that the gaming universe and the metaverse are where the younger generation, such as Gen Alpha, first engages with the fashion industry.

Today, we see numerous initiatives from major brands in the metaverse, demonstrating their strategic role in shaping the future.

Learn more: Explore the fashion metaverse and make your collection stand out

5. New fabrics

Traditional materials and fibers used in garment production contribute significantly to pollution.

However, ongoing research and innovation are leading to the development of alternative fabrics that generate less waste during production and possess qualities such as durability, biodegradability, recyclability, and reusability.

Over the past few years, various fibers have been created from unconventional sources, such as orange peels (Orange Fiber), coffee grounds (S.Café), non-food milk (QMILK), cellulose pulp (Tencel), silk fibers extracted from cobwebs (Microsilk), recycled fibers (Polylana/Evrnu), pineapple leaves (Piñatex), mushrooms (Muskin), and apple peels (Savi Collection).

6. Sales and purchasing models

Sales and purchasing processes in the fashion industry are undergoing significant innovations.

Today, the traditional linear path of manufacturer-importer-wholesaler-shop has evolved. Shops can now directly engage with producers, even without keeping goods in stock, thanks to the possibilities offered by distribution systems like dropshipping.

As revealed in the research study “Brand Relevance Evolution in Fashion”, communities already influence the purchasing decisions of three out of every four Gen Z consumers.

7. Technology

The industry is currently experiencing a significant revolution in fashion technology.

From e-commerce and data analysis to automated production, digital design, and augmented reality, there is a wide range of tools available to optimize processes, increase production efficiency, and reduce waste.

According to the State of Fashion report in 2021, fashion companies have invested between 1.6% and 1.8% of their revenues in technology. By 2030, this figure is expected to increase to 3.0% to 3.5%.

Learn more: How can fashion brands boost their business with technology?

How to cultivate the right attitude for fashion innovation?

Innovation, as we have observed, serves as a constant driving force for change, playing a vital role in maintaining competitiveness within the fashion industry.

However, what truly fuels innovation? Often, it stems from the characteristics and inclinations of individuals within the organization, particularly those in management positions.

Let’s explore three distinct qualities:

Attention and vision

To foster innovation, it is essential to pay attention to and proactively identify fertile areas for investigation.

This involves generating new solutions or ideas that have not been previously applied, adapting existing solutions from other fields, or improving upon current practices.

Individuals open to innovation are typically knowledgeable, curious, dynamic, and receptive to change.

Collaboration and communication

Innovation rarely stems solely from an individual; rather, it often emerges from a collective process involving multiple individuals with diverse backgrounds and skills.

Creating an environment that encourages communication and collaboration is crucial for the birth and sharing of new ideas.

Collaboration allows for the pooling of different perspectives, leading to more innovative outcomes.

Propensity for technological adoption

In today’s world, innovation is closely tied to technology.

There are numerous solutions available in the market that can make a transformative impact on every operational aspect of fashion companies.

Individuals with a strong inclination toward using technology, who stay updated and are willing to learn new tools and instruments, can play a pivotal role in driving corporate innovation.

Learn more: Get to know what GTIN is and its importance for the clothing industry

How to enhance productive processes and foster innovation?

By embracing digital transformation and facilitating collaboration between education and industry, fashion businesses can foster greater innovation within their productive processes.

Check out some key topics that can be helpful in this matter:

Digitizing production and management processes

One crucial aspect of driving innovation within productive processes is investing in technologies that enable the digitization of production and management processes.

This includes implementing CAD modeling, automated cutting rooms, and management software.

Digitization brings agility, increased production efficiency, resource and raw material savings, reduced errors and rework, and improved communication among team members, even in remote settings.

Continuous collaboration between education and industry

In response to the transformations of Industry 4.0, the required skills for fashion professionals are evolving.

It becomes increasingly important to stimulate an ongoing dialogue between educational institutions and the industry, aiming to enhance the alignment between supply and demand.

Boost fashion innovation in your company with Audaces technologies

Audaces is at the forefront of the fashion industry’s progress, continuously developing innovative solutions to meet the needs of the textile sector.

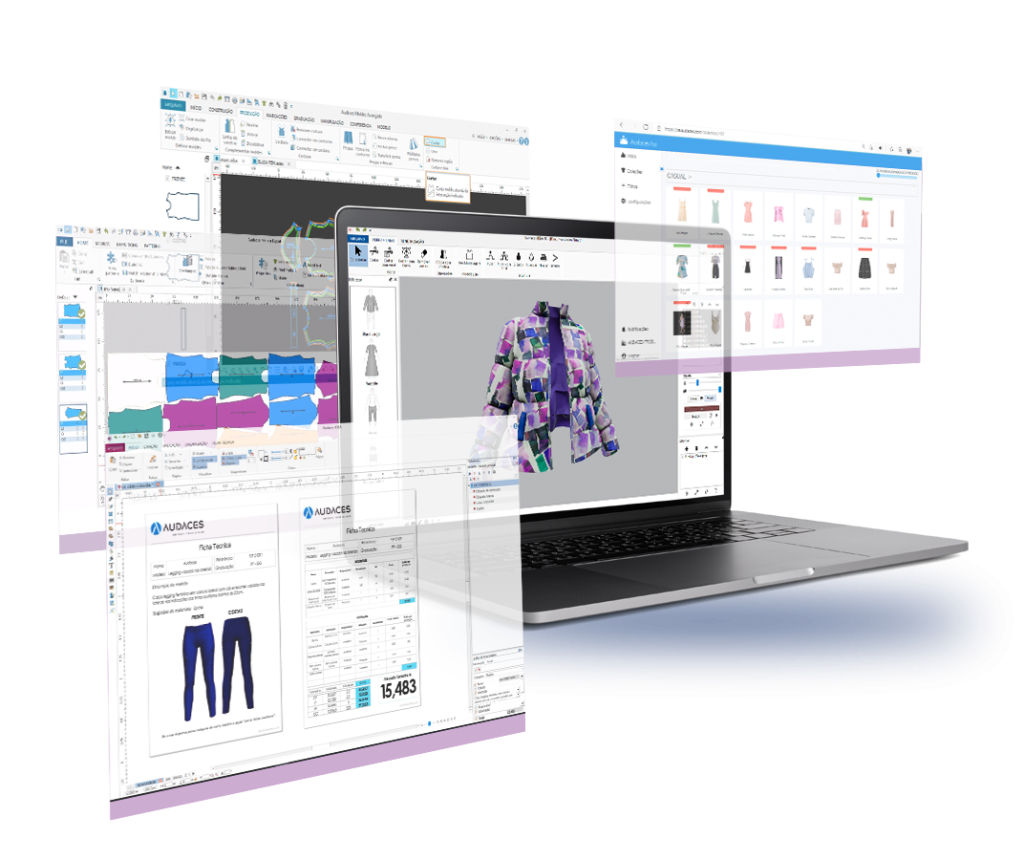

Among these solutions is Audaces360, an ecosystem that integrates the most advanced technologies currently available in the fashion market.

Audaces360

Audaces360 is the perfect ally for those seeking to achieve better results by optimizing creative talent and resources through efficient and integrated management.

This advanced technological platform enables users to reach their goals and overcome the main challenges of the market.

With its innovative concept of integrating the creative and productive phases, Audaces360 offers a complete multi-solution, empowering you to ensure the success of your collections.

Audaces Fashion Studio

Audaces Fashion Studio, an integral component of the Audaces360 platform, is an advanced software for digital fashion design. It empowers users to develop both physical and virtual clothing items with ease.

This unique solution streamlines visual communication among teams and facilitates model approvals, significantly reducing production time and the need for excessive prototypes. In essence, Audaces Fashion Studio represents the present and future of the fashion market, all in one comprehensive solution.

Audaces Isa

Audaces Isa is a cloud-based collection management software that enables efficient management of the product lifecycle throughout the entire production chain.

With Isa, you can ensure adherence to deadlines, make more informed decisions, and effectively organize the technical aspects of your collection.

If you are interested in learning more about the challenges faced by the industry and the innovative solutions available in the metaverse to bring fashion innovation to your company, download our free e-book by filling out the form below:

FAQ

In the realm of fashion, innovation encompasses the pursuit of new approaches to design, manufacturing, and sales. It can involve enhancing product offerings, establishing new customer relationships, and reevaluating existing processes.

There are seven notable trends shaping innovation in the fashion world: sustainability, blockchain, augmented reality, metaverse, new fabrics, evolving sales and purchase models, and the integration of technology.

To foster innovation in fashion, it is crucial to possess an attentive and visionary mindset, promote collaboration and effective communication, and embrace a propensity for utilizing technology.