Summary

- From design to production, you can apply clean technology in many ways in your fashion business.

- You’ll find that these tools not only benefit the environment but also save businesses money and time.

- Leverage technology to boost your efficiency. Try Audaces360 for free and discover how!

The textile industry is changing. Sustainability is no longer an option — it’s a necessity. And clean technology is leading this transformation.

More and more companies are looking for ways to reduce waste, save resources, and improve efficiency. But what exactly does clean technology mean in clothing manufacturing?

We’re going to walk you through practical examples, applications, and the benefits of sustainable technology. You’ll learn everything you need to make smart investments in your company’s future.

Happy reading!

Sumário

Why is clean technology so important in the textile industry?

Clean technology helps reduce waste by optimizing resources. It enables manufacturers to use less water, energy sources, and raw materials. The result is cost savings and reduced environmental harm.

For example, digital pattern making and 3D garment simulation cut down the need for physical samples. This saves materials and reduces waste.

Moreover, clean technology helps companies comply with environmental regulations. Many countries are implementing stricter sustainability laws for industries, including textiles.

Adopting clean tech solutions ensures that businesses meet these standards while staying competitive in the market.

Finally, using clean technology improves a company’s reputation. Consumers are becoming more environmentally conscious. They prefer to buy from brands that are committed to sustainability.

Learn more: Discover where fashion law applies and why you should comply

What is clean technology?

Clean technology, or “cleantech,” refers to products or services that use sustainable sources. They aim to minimize the negative environmental impact.

This includes technologies that reduce energy consumption, waste, and emissions. The goal is to create more sustainable processes that can help protect the environment.

In the textile industry, clean technology includes solutions that help businesses reduce their carbon footprint. This could be through energy-efficient machinery or waste reduction methods.

It also involves the use of eco-friendly materials and the recycling of textile products, encouraging a circular economy.

The energy sector is another important area to consider. When it comes to environmental protection, reducing our dependence on natural resources is crucial.

Renewable energies, like solar energy, are considered a clean energy source for businesses. Remember, it’s not only about being environmentally friendly but also about improving efficiency.

By using cleaner processes, businesses can lower operational costs. For instance, automating tasks can also save time and reduce the need for manual labor.

Learn more: How to master sustainable creation and production in the eco fashion era

Examples of clean technology worth investing in

Design and tech pack software

Design and tech pack software saves valuable time in the fashion design process. Professionals can create and store detailed sketches and tech packs digitally, eliminating the need for paper and printing.

With this kind of software, you can easily update designs and share them with your team or suppliers. This helps reduce errors and speeds up the production process.

Also, digital files are easy to manage, allowing for quick revisions without needing to reprint multiple versions.

Online collection manager

An online collection manager is a great tool for organizing and tracking your collections. It saves time by centralizing all the information in one easy-to-use platform.

This system helps reduce delays and errors during the collection process. By having all the information digitally, there’s less room for communication problems.

The 360-degree tracking feature provides full visibility into every stage of the collection’s development.

Learn more: 6 benefits of having an online collection management

Digital pattern making systems

Digital pattern-making systems offer a way to create patterns without wasting time or paper. Professionals can create, modify, and store digital patterns directly on their computers.

This reduces the need for physical patterns and saves valuable storage space.

Using digital tools for pattern making also speeds up the process. Designers can make quick adjustments, without the need to cut and sew fabric manually.

The system enables faster iterations, helping to streamline the overall design process.

Learn more: What is the best way to create a pattern of clothing?

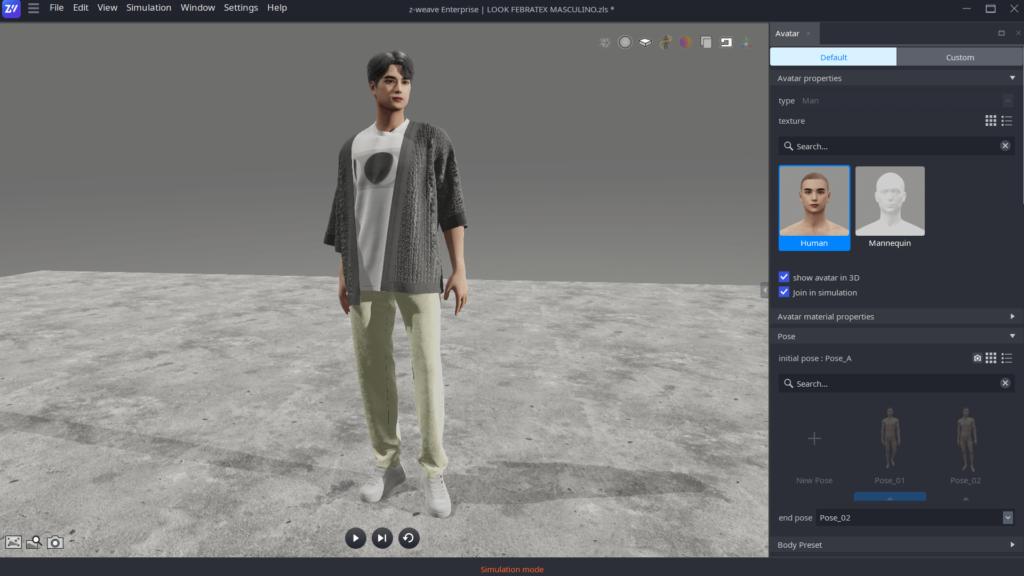

3D design simulator

A 3D design simulator allows you to create virtual prototypes of your designs, saving both time and fabric.

It eliminates the need for physical samples, which can take time to produce and waste valuable resources. You can visualize designs in 3D before making them, helping to catch any design flaws early.

Using this technology helps you make better decisions. You can experiment with different colors, prints, and fabrics without committing to physical samples.

Learn more: 5 reasons why pattern makers should start using 3D pattern

Cutting plan manager

A cutting plan manager helps optimize fabric usage, reducing waste and saving time. The system creates the most efficient cutting plan, ensuring you always use fabric wisely.

By minimizing fabric waste, you save money and contribute to a more sustainable production process.

With a cutting plan manager, you can prioritize the most urgent orders. It helps organize workflows and speeds up the overall manufacturing process.

In addition to saving fabric, the system helps streamline production scheduling.

Unlock the secrets to efficient and sustainable textile production! Download our exclusive e-book for free now.

What are the applications of clean technology in the garment industry?

Clean technology is transforming the garment industry by promoting efficiency and sustainability. It’s a clean technology investment to apply to design, development, and production processes.

Collaborative creation

Systems that connect designers, pattern makers, and production teams allow for quick adjustments in designs and sizes. It makes it easier to meet customer demands in real time.

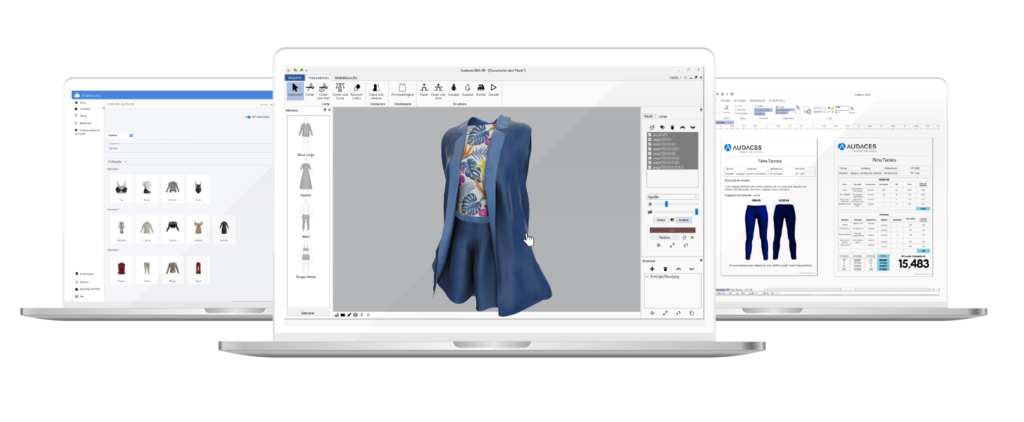

Solutions like Audaces Isa streamline collection management with fashion PLM technology. You can centralize all your data on a single platform and monitor progress.

Audaces Fashion Studio enables 3D design, giving you everything you need to create and approve garments digitally.

Meanwhile, Audaces Idea has all the tools you need to create flat sketches faster and integrate them with tech packs and pre-cost.

By enabling collaboration across teams, integrated systems also help reduce stock. Instead of overproducing, companies can tailor production to meet demand, which reduces waste and storage costs.

Learn more: Why invest in collaborative creation in fashion business?

Digital pattern making

Digital pattern making is a key clean technology application in the garment industry. Solutions like Audaces Pattern enable designers to create, modify, and save patterns digitally.

This eliminates the need for paper patterns and reduces physical waste.

If you’re still using manual pattern making, Audaces Digiflash can help you make the switch to digital. Just take a picture with your phone, and your pattern is ready to edit on your computer.

In addition to being efficient, digital pattern making is accurate. The software ensures that patterns are precise, reducing errors in the production process.

This results in fewer mistakes and lower material waste, which is essential for sustainable production.

Virtual prototyping

Virtual prototyping allows pattern makers to test digital versions of garments without making physical samples.

Audaces 3D is a great example of this clean technology, enabling professionals to test their patterns before production.

It helps identify potential issues before cutting any piece of fabric, reducing the need for multiple prototypes.

Smart marking

Smart marking technology optimizes fabric use during the cutting process. For this purpose, Audaces Marker and Audaces Supera help minimize fabric waste.

They do it by arranging patterns in the most efficient way. This reduces the amount of fabric necessary and decreases production costs.

Above all, it’s a super-fast system that reduces energy consumption compared to manual methods.

Artificial Intelligence

Artificial intelligence (AI) is playing a major role in the garment industry by improving efficiency and decision-making.

There are examples of AI-powered solutions that assist designers and manufacturers in optimizing production.

Audaces Sofia, for instance, uses Artificial Intelligence to turn sketches into realistic images while suggesting print options and model variations.

Audaces ICF, on the other hand, is the intelligent system behind the cutting machine. It manages the cutting process by organizing cutting queues, sending machine stop alerts, and providing performance insights.

Benefits of using clean technology in your clothing manufacturing

Less waste of time and resources

Clean technology makes production faster. Automated systems speed up tasks that used to take hours.

Moreover, smart machines cut fabric with precision, avoiding unnecessary scraps. This means less material waste, saving money and the environment.

Efficiency also improves team productivity. Workers spend less time fixing errors or redoing tasks. With better clean technology tools, they can focus on quality and creativity.

Reduction of excess inventory

Producing only what is necessary prevents overstock. And clean technology helps track demand and adjust production accordingly.

Digital solutions improve planning. They analyze trends and sales history to predict what customers will buy. This reduces the risk of making too much of the wrong product.

After all, less excess inventory means lower costs. Businesses save on storage, transportation, and materials.

Higher product quality

Clean technology ensures precise development and cutting. Smart systems and automated machines work with accuracy, reducing defects. This leads to better-fitting garments with a polished look.

This consistency in production improves brand reputation. Customers notice when clothes last longer and look well-made.

Also, quality control is easier. Digital monitoring detects issues early, preventing faulty items from reaching stores and reduces returns.

Access to collection history and data

Technology keeps a record of past collections. Designers and pattern makers can review what worked and what didn’t. This helps in making better decisions for future designs.

Data improves efficiency. It shows trends, fabric usage, and customer preferences. With this information, brands can create products that sell well.

Having access to history also speeds up the design process. Instead of starting from scratch, designers can build on past successes, saving time and fostering innovation.

Turn your clothing manufacturing sustainable with Audaces clean technology

See how Audaces technology helps you improve product quality, optimize your processes, and promote sustainable practices.

Audaces360

Audaces360 integrates cutting-edge digital innovations to optimize workflows in the textile and apparel industry.

It caters to companies of all sizes and types, offering the flexibility to scale with your business needs.

We carefully developed all solutions to address the field’s specific challenges. They streamline the design and production processes, saving valuable time and resources.

The platform boasts a comprehensive range of functionalities, including pattern making, marking, collection management, vector drawing, and 3D creation.

In addition, a fashion Artificial Intelligence to assist you along the way.

Audaces ICF

Audaces ICF is an intelligent technology that connects people and cutting room equipment with high security.

It’s fully digital and focused on data security. It provides the best tools for planning and managing spreading and cutting processes.

In addition to streamlining your workflow, the online platform ensures access for all stakeholders. All information is available in real time via smartphone.

Managers can effortlessly schedule cut orders, specifying details like spreads, layers, cuts, and fabric quantities.

Moreover, Audaces ICF monitors and alerts about differences between planned and actual results, with automatic correction suggestions.

Was this article helpful? Get our latest content first by subscribing to the Audaces newsletter!

FAQ

Clean technology helps reduce waste by optimizing resources. It enables manufacturers to use less water, energy sources, and raw materials. The result is cost savings and reduced environmental harm.

Clean technology, or “cleantech,” refers to products or services that use sustainable sources. They aim to minimize the negative environmental impact.

Design and tech pack software, online collection manager, digital pattern making systems, and 3D design simulator.