Summary

- Efficient fabric cutting is essential for quality and cost-effective garment production.

- By following these pro tips, you’ll improve your process and reduce waste.

- Discover the complete solution for every stage of the fashion industry. Try Audaces360 for free today!

Knowing how to cut fabric efficiently is key to a smooth apparel manufacturing process. It can impact the quality of your products and the cost of production.

In this article, we’ll share seven pro tips on how to cut fabric with precision. These tips will help you avoid common mistakes and improve your workflow.

By the end of this guide, you’ll have a clearer understanding of the best practices in fabric cutting.

Happy reading!

Sumário

Why is cutting fabric one of the most important steps in production?

Cutting fabric is key in garment production because it directly impacts the fit and quality of the final product.

If you don’t cut the fabric correctly, it can lead to issues such as uneven seams or misaligned patterns pieces. This can cause waste and delays in production, making it essential to get it right from the start.

Moreover, cutting fabric precisely helps reduce waste. By using the fabric efficiently, manufacturers can make the most out of their materials.

It’s not only good for the bottom line but also supports sustainability efforts in the fashion industry.

How to cut fabric for maximum efficiency?

If you want to ensure a fast and cost-effective production process, follow our tips on how to cut fabric the right way.

Plan your cutting

Planning is essential for efficient fabric cutting. Before start cutting, make sure to calculate how much fabric you need for each garment.

It will help you avoid wasting fabric and ensure that you have enough material for all the pieces.

Additionally, you should arrange the pattern pieces in a way that minimizes fabric use. This can involve rotating patterns or placing them in a way that maximizes the available space.

It’s even better when you use a complete solution. This lets you create digital patterns and perfect markers. You can be sure of getting top-quality results.

Learn more: How can a good cutting plan transform your production?

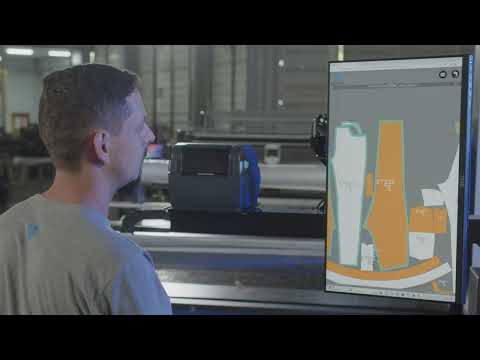

Use an automated cutting machine

Automated cutting machines improve the accuracy and speed of fabric cutting. These machines use technology to cut patterns with high precision, reducing human error.

The result is cleaner edges and better-fitting pieces for the final product.

They also help speed up production by cutting multiple layers of fabric at once. This increases efficiency and reduces the time on each garment.

Compared to a rotary cutter, this kind of machinery is a game-changer. Manual cutting around the pattern is time-intensive and increases the risk of errors.

The challenges are amplified with slippery fabrics like silk and faux leather. These materials require weights to hold them stable on the cutting table, but those weights can easily create issues.

With automation, the cutting process becomes faster and more consistent, making it easier to keep up with production demands.

Learn more: How does leather cut work in fashion manufacturing?

Check for fabric defects

Before cutting, inspect the woven fabrics for defects. Look for issues like stains or holes in the raw material.

Identifying these problems early on can help avoid wasting time on defective pieces of fabric.

By checking the fabrics thoroughly, you can ensure that only the best quality material goes for the cutting stage.

This helps maintain the standards of the final product and prevents potential costly mistakes later.

Identify the fabric’s grain

Understanding the fabric’s grain is key to cutting it correctly. The grain refers to the direction of the threads in the fabric, which affects how it behaves

Cutting along the grain ensures that the fabric stretches and fits as intended. On the other hand, cutting against the grain can lead to issues like distortion or uneven fit.

Make sure to align the pattern pieces with the fabric’s straight grain to maintain the garment’s shape and quality. This simple step can make a big difference.

Learn more: 7 pro tips on how to cut fabric for garment manufacturing

Prepare the fabric for cutting

Proper fabric preparation is crucial for efficient industrial cutting. Begin by ensuring the fabric is free of wrinkles and properly aligned.

This step ensures smooth handling and prevents misalignment during the cutting process.

Next, lay the fabric flat on a clean, stable surface or cutting table. It will help maintain even layers and minimize the risk of distortion.

Remember that good preparation makes sure the fabric is ready for cutting. This helps reduce mistakes and improves cutting accuracy.

Learn more: Why invest in a good fabric cutting table for garment production?

Consider the most suitable spreading method

Spreading refers to the process of laying the fabric flat before cutting. The method you choose depends on the type of fabric and the volume of production.

For large runs, an automated spreading machine can help lay out fabric quickly and evenly. For smaller batches, manual spreading may be sufficient.

The key is to ensure that the fabric is spread smoothly to avoid wrinkles or uneven layers.

Manage the process with good software

Using good software can help streamline the fabric cutting process. Software can assist with collection management, precise markers, and even managing cutting orders.

With the right digital solution, you can track fabric usage, monitor defects, and optimize cutting layouts.

This leads to less waste and better management of resources, which ultimately helps reduce costs and improve productivity.

Learn more: 7 key factors to look for in the best fabric cutting systems

Ready to optimize your cutting room? Download our guide and learn how to eliminate costly mistakes!

How to tell the right side of the fabric when cutting?

Follow these 5 simple steps to find out how:

- Check the texture: The right side is usually smoother and softer, while the wrong side may feel rougher.

- Look at the print or shine: Printed fabrics have brighter colors on the right side. Shiny fabrics often have more gloss on the correct side.

- Find the selvage: The right side is usually the one where the selvage edges roll inward slightly.

- Check the labels or markings: Some fabrics have markings from the manufacturer indicating the right side.

- Stretch the fabric: Knitted fabrics curl towards the wrong side when stretched at the edges.

Benefits of automating fabric cutting in production

Automating fabric cutting offers numerous benefits for fashion manufacturers. See the key advantages:

Increased productivity

Automation makes cutting faster and more efficient. Machines can cut multiple layers at once, reducing the time for each batch.

With faster production, companies can meet deadlines more easily. They can also handle larger orders without increasing labor costs.

Learn more: Learn why automation is key to optimize the cut process

Greater precision and final quality

Automated cutting ensures clean and accurate cuts. This reduces errors that can lead to fabric waste or defective pieces.

The result is consistent quality in each garment, improving the final product.

Precision cutting also helps with complex designs. Intricate patterns and details are easier to achieve, enhancing the overall look and fit of garments.

Waste reduction

Manual cutting often leads to unnecessary fabric waste. Meanwhile, automation optimizes material usage, reducing scraps and saving costs.

Smart software calculates the best layout for cutting, minimizing leftover fabric.

Less waste means lower production costs and a more sustainable process. Companies can use fewer raw materials while maintaining high output.

Error and failure recognition

Smart systems detect cutting errors in real time. If a mistake happens, the machine can stop and alert operators. This prevents defective pieces from moving forward in production.

Early error detection reduces rework and material loss. It also improves efficiency by ensuring only high-quality pieces continue in the process.

Real-time monitoring

Production managers are able to track production in real time. Systems provide data on speed, accuracy, and material usage. This helps identify bottlenecks and improve workflow.

In addition, real-time monitoring allows for quick adjustments. If an issue arises, operators can fix it immediately, keeping production on schedule.

To achieve this, make sure your machine’s maintenance is always up to date. This ensures optimal performance and extends its lifespan.

Learn more: Learn why regular maintenance is crucial for fabric cutting machines

Integration with other production stages

Automated cutting systems can integrate with design and development stages. Pattern-making files can be sent directly to cutting machines using digital markers.

This approach reduces manual work and speeds up the transition between steps.

As a result, seamless integration improves coordination across departments. It also ensures that patterns and designs are cut exactly as planned, reducing errors.

Learn more: The ultimate guide to create a marker for fabric cutting

Market competitiveness

Companies that automate fabric cutting gain a competitive edge. Faster production, higher quality, and reduced waste make them more efficient. Businesses can offer better prices and meet customer demands.

Staying ahead in the market requires innovation. Automation helps manufacturers adapt to industry trends and remain leaders in the fashion industry.

However, technology alone isn’t enough. Skilled professionals are essential to operate machines, interpret data, and make strategic decisions. When technology and human expertise work together, results reach their full potential.

Learn more: All you need to know about the fabric cutter profession

Automate your fabric cutting with Audaces

Audaces Cutting Room

By embracing cutting-edge technology, garment manufacturers can achieve significant improvements in the production process. From greater design flexibility to enhanced efficiency and reduced costs.

This is where Audaces Cutting Room steps in! Our experts will thoroughly assess your company’s needs and create a comprehensive report.

Then, our team will develop a personalized project to achieve your goals and unlock your company’s full potential.

Rely on Audaces’ cutting-edge hardware and software to automate your production process. Achieve impeccable cuts on curves and details, speeding up your deliveries and minimizing fabric waste through automation.

For all your cutting needs, our cutting room has you covered. We offer everything from production monitoring software to the latest spreading and cutting machines for maximum efficiency.

See how our software Audaces ICF connects machines and people to transform your production in practice!

Was this article helpful? Get our latest content first by subscribing to the Audaces newsletter!

FAQ

Cutting fabric is key in garment production because it directly impacts the fit and quality of the final product.

Plan your cutting, use an automated cutting machine, check for fabric defects, identify the fabric’s grain, prepare the fabric for cutting, consider the most suitable spreading method, and manage the process with good software.

Check the texture, look at the print or shine, find the selvage, check the labels or markings, and stretch the fabric.