Summary

- Discover how sewing and patterns work together to shape the success of any garment.

- Learn practical ways to streamline communication, workflows, and decision-making between these two stages.

- Get monthly fashion insights straight to your inbox. Subscribe to our newsletter!

Sewing and patterns have a deep connection in fashion production. One depends on the other, and small decisions in pattern development can influence the entire sewing stage.

However, many pattern makers still face common challenges. Miscommunication, missing technical details, unclear sewing instructions, or last-minute adjustments can create delays and frustration.

The good news is that with the right tools, practices, and mindset, it becomes simple to align both steps. In this article, you’ll find everything you need to simplify this connection and make your work easier.

Happy reading!

Sumário

What is the connection between sewing and patterns?

Sewing and patterns are two stages of garment development that work hand in hand. A well-developed pattern forms the foundation of a garment, while sewing brings that blueprint to life.

When both processes align, the result is consistent, functional, and true to the original design vision.

Pattern makers rely on sewing practices to validate what works and what needs improvement. They need to translate every curve, dart, and shape with precision. This way, sewists can assemble the garment without confusion or excessive adjustments.

On the other hand, sewists depend on clear instructions, logical construction methods, and patterns that respect fabric behavior.

Main challenges in pattern making for sewing

Pattern making plays a critical role in fashion production, but it also comes with recurring challenges. Here are the most common ones:

Achieving the perfect fit

Fit is one of the biggest priorities in pattern development, yet also one of the most complex.

Every body is different, and even small adjustments in measurements can dramatically change how a garment feels and looks.

Achieving an ideal fit becomes easier when teams rely on testing and technology. Prototyping, digital simulation tools, and collaboration with sewists help refine details before mass production.

Working with multiple size ranges

Pattern makers must also adapt a single base model into a full scale of sizes. This requires precision because grading isn’t only about making a pattern bigger or smaller. Proportions change, curves shift, and functional ease must remain consistent throughout all sizes.

When grading is perfect, every size maintains the same level of comfort and style identity.

Handling complex designs

Some styles involve advanced construction details, such as asymmetric cuts, draping, panels, or built-in supports. These elements require careful planning and testing during the pattern making stage. This way, the sewing process remains manageable and efficient.

With complex garments, documentation becomes especially important. Clear sewing instructions, well-marked notches, and organized layouts help avoid confusion and rework. The goal is to make even challenging garments intuitive to assemble.

Read more: 7 reasons to go digital with your handmade pattern

Choosing the right materials

The type of fabric used has a major impact on how a garment behaves.

Stretch fabrics, for example, require different ease calculations than structured woven fabrics. The wrong choice or lack of compatibility between design and material can compromise fit and comfort.

Testing prototypes and understanding shrinkage, elasticity, drape, and thickness reduce unexpected issues later in sewing.

Integrating new technologies

Digital tools make it easier to test ideas, correct mistakes, and create variations without starting from scratch. Features like automated grading, virtual prototyping, and 3D fitting save time and provide better accuracy.

However, even with technology, the human skill behind pattern making remains essential. Tools support decision-making, but creativity, technical knowledge, and practical experience guide the final result.

Read more: 6 signs you’re ready to move to 3D prototyping

Why is there a shortage of skilled sewists in the fashion industry?

The fashion industry has evolved quickly, and many sewing roles shifted or disappeared with automation and outsourcing. As production moved overseas or relied heavily on mass manufacturing, fewer people pursued sewing as a profession.

Today, demand has resurfaced, but the talent gap remains because fewer new professionals entered the field during this transition.

To overcome this shortage, the industry needs to rethink how it values sewists.

Offering better working conditions, fair compensation, and continuous training can make this role more attractive and respected. Encouraging education programs, apprenticeships, and certification pathways helps elevate technical sewing as a specialized profession.

How can sewing and patterns processes be improved?

Small adjustments in workflow can make a big difference in efficiency and final garment quality! Check it out:

Select fabrics carefully before developing patterns

Testing fabric shrinkage, elasticity, and how it responds to movement or heat helps reduce inconsistencies during production.

This step saves time and prevents rework by ensuring the design and material are compatible from the beginning.

Use technology to make your workflow more efficient

Digital tools help reduce manual steps in pattern making and sewing preparation. Features like automated measurements, simulation, and editable templates allow pattern makers to test ideas faster and correct mistakes with precision.

Discover how to use CAD software to optimize your process. Download our exclusive free guide now!

Grade your patterns for all required sizes

When grading is accurate, every customer receives a garment that fits comfortably and reflects the original design intent.

Automated grading tools make the process faster and more reliable, especially for collections with multiple sizes.

Read more: Discover 5 major benefits of 3D simulation for fashion

Create a smart and optimized cutting plan

A cutting plan helps minimize waste and makes production more predictable. By streamlining pattern placement, teams avoid fabric waste and ensure a clean workflow.

Follow production from start to finish

Monitoring production allows pattern makers to validate decisions and identify improvements. Observing the assembly of pieces helps highlight areas where instructions may be unclear or patterns may need adjustments.

Maintain good communication with other teams

Pattern development doesn’t happen in isolation. Clear communication with sewists, designers, and production teams ensures everyone understands the garment’s construction logic and expected results.

5 benefits of high-quality pattern making in production

1) Reduces mistakes and rework

When patterns are well-developed, the sewing stage becomes clearer and more predictable. Teams avoid unnecessary corrections and prototypes, saving time and materials.

2) Cuts fabric waste

Precision in pattern development and smart cutting planning ensure fabric usage is more efficient. This reduces material cost and makes production more sustainable.

3) Improves garment quality

Accurate patterns lead to better structure, fit, and finishing. This results in garments that look professional, feel comfortable, and meet customer expectations.

4) Speeds up and scales production

Standardized and organized patterns allow factories to work faster and produce larger quantities without compromising quality.

5) Makes approval faster and smoother

When prototypes match expectations the first time, decision-making becomes simpler. Approvals happen faster, keeping timelines on track.

How can you integrate technology into your pattern making workflow?

Digitizing patterns

Digitizing replaces paper-based workflows and makes patterns easier to update, store, and share. Once digital, you can modify patterns without repeating the entire drafting process, bringing agility and precision to revisions.

This also enhances consistency across collections. Digital patterns maintain standard measurements and ensure production files remain organized and accessible for the future.

Read more: How to digitize sewing patterns in 5 simple steps

Automating size grading

Automated grading tools eliminate repetitive manual work and ensure every size follows the same construction logic.

Instead of redrawing lines for each size, pattern makers can adjust measurements quickly while maintaining proportional accuracy.

This not only saves time but also reduces the chance of mistakes caused by manual adjustments. It ensures a more reliable and scalable workflow for brands developing multiple sizes.

Read more: Why is a grading tool essential in efficient software?

Working with 3D development

3D modeling allows pattern makers to test garments virtually before creating physical prototypes. This helps identify fit issues, construction challenges, or design inconsistencies early in the process.

Virtual samples reduce the need for multiple physical versions, cutting down waste and speeding up approval.

With these tools, pattern makers can visualize results faster and make informed decisions with confidence.

Read more: Learn how to create a clothing size chart for your brand

Create and simulate your sewing patterns using Audaces technology

Audaces is a market leader fashion technology company and a reference worldwide. Through a deep understanding of fashion creation and production, we have developed ideal solutions for each stage.

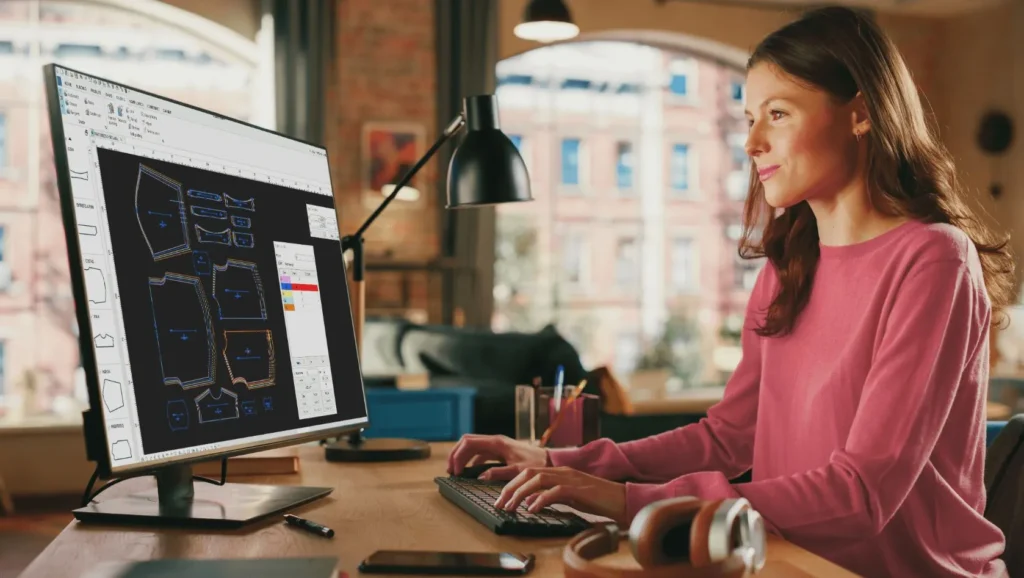

Audaces Pattern

Audaces Pattern is the perfect solution to simplify and speed up your pattern-making process. With intuitive digital tools and smart automation, you can create, edit, and grade patterns efficiently.

Save valuable time and can focus more on the creative and technical decisions that truly shape your collection.

When changes happen, you won’t have to start from scratch. The software makes it easy to adjust measurements, reshape pieces, and test new design variations with precision and speed.

To take it even further, Audaces Pattern integrates seamlessly with the full Audaces ecosystem. This connection allows you to plan, develop, and produce with consistency and accuracy across every stage.

Audaces 3D

Audaces 3D is ideal for pattern makers to bring creations to life in a 3D mannequin.

You can test your digital pattern before committing to a physical sample. Save time and resources by identifying issues early in the process.

With a range of tools and possibilities, this software transforms the development processes.

It enables you to shape your ideas directly in a digital space, gaining agility and quality in deliveries.

Discover Audaces360 and unlock a world of possibilities for fashion design and production. Explore our comprehensive suite of solutions today!

FAQ

Sewing and patterns are two stages of garment development that work hand in hand. A well-developed pattern forms the foundation of a garment, while sewing brings that blueprint to life.

They include achieving the perfect fit, working with multiple size ranges, and handling complex designs.

As production moved overseas or relied heavily on mass manufacturing, fewer people pursued sewing as a profession. Today, demand has resurfaced.To overcome this shortage, the industry needs to rethink how it values sewists.