Summary

- Pattern making is all about precision. Every line, curve, and measurement matters.

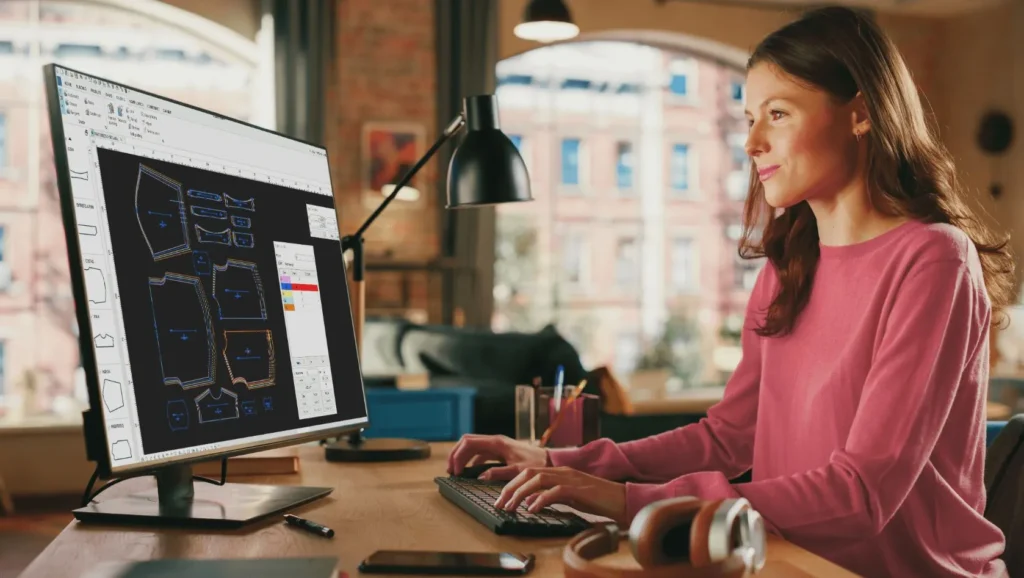

- The best way to guarantee that is by combining skilled professionals with smart technologies.

- Experience the future of the fashion industry with Audaces360. Start your free trial now!

If you’ve been using handmade patterns, you know how important it’s to keep everything consistent and accurate. But have you ever thought about what could change if you took your work digital?

This shift isn’t about changing the way you work. It’s about making the process faster, more efficient, and easier to manage. And digital solutions can help you save time, avoid errors, and stay organized.

In this article, we’ll share 7 reasons why making the switch makes sense. You’ll find everything you need to help you take the next step with confidence.

Enjoy your reading!

Sumário

Why is the handmade pattern falling behind?

Pattern making by hand has been around for a long time. It’s how many professionals first learned the craft. But today, things are changing.

The fashion industry is moving faster than ever. Shorter deadlines and greater demand mean there’s less room for delays or errors. In this context, handmade patterns can slow things down.

Making a pattern by hand takes time as you must do every step carefully. Even a small mistake can affect the final garment.

This risk of imprecision is one of the main reasons why many professionals are turning to digital methods.

Sewing patterns made by hand are also harder to store and share. They take up space and can get damaged over time. In contrast, digital files are easy to organize and send.

As a result, the manual method is less and less common. It’s not that it doesn’t work, but it can’t always keep up with today’s demands.

Learn more: What is the best way to create a pattern of clothing?

What’s the difference between handmade and digital patterns?

The biggest difference is in the tools and the time. To create handmade patterns, you need paper, rulers, and pencils. Digital patterns require a computer with specialized software.

With handmade patterns, you must draw every line by hand. That means more chances for errors. If something changes, you often need to start over or make slow corrections.

Digital patterns are faster to create and change. The software helps ensure every line and curve is precise. It also makes it easier to scale patterns to different sizes.

Manual work also takes much more time. A simple change can take hours when done by hand. In digital tools, you can make the same change in minutes.

Learn more: What is pattern design and how to create it from scratch?

7 reasons to switch from handmade to digital pattern making

Switching from handmade to digital pattern making brings many benefits. It’s a smart step for those who want to improve speed, accuracy, and results. Check it out:

1) Digitize your patterns with a single click

Converting your paper patterns into digital format no longer needs to be hard. With the right tool, this step becomes quick and easy.

Audaces Digiflash lets you digitize your patterns with a single photo. Just place the paper pattern on the board, take a picture, and the system does the rest.

With everything digital, your patterns are easier to store, organize, and access whenever you need.

2) Greater precision and consistency

Handmade patterns rely on steady hands and careful eyes. But even the best professionals can make small mistakes.

A major benefit of digital solutions is that they help reduce those risks. They allow you to draw and adjust lines with perfect accuracy, using automated tools.

This means every piece will match, and sizes will be consistent. No more guessing or rechecking measurements!

In the end, digital patterns help you produce better-quality garments, with fewer errors.

3) Faster processes

Making patterns by hand takes time. You must draw, cut, review, and adjust them on paper, often more than once.

With the right digital solution, the whole process speeds up. Use existing files as a base, make changes and tests as many times as you like.

You no longer need to start from scratch when something changes. Just update the file, and that’s all! This speed helps you meet deadlines and produce more in less time.

4) Automatic grading

Grading patterns is a long and complex task. It requires calculations and several manual processes because the garment needs to fit well in all sizes.

To do this quickly and accurately, nothing beats an automatic grading tool. With this kind of technology, you just enter the tech pack data, and the system does the rest.

This avoids manual repetition and reduces errors. You also gain more control over each step.

Learn more: What is grading and how to do it in 3 simple steps

5) Save time and resources

Working by hand means more paper, more printing, and more hours. These small things add up fast.

Digital pattern making cuts those costs. You spend less on materials and use your time more efficiently. This is because changes no longer mean redoing everything. You just open the file and make the update.

In the long run, digital tools help you save money while doing more.

Is pattern making a source of stress for you? Discover how to overcome key challenges in pattern making and marking with our exclusive content. Download your free copy now!

6) Easier adjustments

Patterns often need changes. A new fit, a different length, or small corrections. By hand, this means redrawing and cutting again.

Digitally, on the other hand, it’s much simpler. Technology helps you respond quickly and test ideas without extra work.

You can zoom in, adjust a line, and see the result right away. No paper wasted, no need to start over.

7) 3D simulation of prototypes

Testing a pattern used to mean making multiple physical samples. Those take lots of time, fabric, and effort.

With solutions like Audaces 3D, you can simulate your pattern on a virtual mannequin. Reducing the number of fabric samples allows you to approve your collections much faster.

Specialized tools help you check fit, shape, and style before cutting anything. You can make changes and try again instantly.

It’s a smarter way to test your patterns and get results faster, with less waste.

Learn more: 5 reasons why pattern makers should start using 3D pattern

How to switch from handmade to digital pattern making?

Making the switch to digital pattern making may seem like a big step. But with the right plan, it’s easier than you think.

This change can save time, improve your results, and bring more control to your work. Here’s how to start, step by step:

Evaluate your business needs

Before switching to digital, take a look at your current process. What takes the most time? Where do mistakes happen?

Think about your goals. Do you want to save time? Improve accuracy? Grow production? These answers will help guide your next steps.

Also, check how your team works today. Are they open to using new tools? Will they need training?

Look at your equipment too. Do you already have computers and space for the new system?

By understanding your needs, you’ll know what to focus on first and avoid wasting time or money later.

Choose the right software

Not all digital pattern tools are the same. Some are simple, while others have more features.

Choose software that matches your goals. If you want fast grading and easy editing integrated with 3D simulation, make sure the system includes everything.

Also, check if the software offers support, tutorials, or updates. This makes a big difference as you grow.

Keep in mind that the right software should help you work faster and better, without adding stress to your routine.

Learn more: All you need to know before investing in CAD/CAM system

Train your team to use it

Once you choose your software, it’s time to train your team. This is a key step in making the switch work.

Everyone needs to feel confident using the new tools. That’s why good training is so important. It helps avoid mistakes and saves time later.

Start with the basics. Show how to open the software, create patterns, and save work. Then, move on to more advanced features, like grading or editing.

You don’t have to do this alone. Educational platforms like Audaces Academy offer online courses and tutorials. They are easy to follow and made for fashion professionals.

With the right training, your team will feel ready and excited to work in a digital way. It’s a smart investment for the future.

Learn more: 6 types of pattern making courses to enhance your skills in fashion industry

Digitize your pattern archive

Your paper patterns hold value, so don’t leave them behind. Instead, bring them into your digital world.

Start by organizing your patterns. Pick the ones you use most often: those should come first. Then, use solutions to scan and digitize your patterns quickly.

Once your patterns are digital, you can update, grade, and store them with ease. No more lost or damaged pieces.

This step builds the base for your new process. With your full archive ready, you can focus on creating, not searching for papers.

Automate your pattern making process with Audaces systems

Audaces Digiflash

While traditional handmade patterns have served their purpose, they often come with drawbacks. They include space constraints, confusion, and loss.

Audaces Digiflash offers an innovative solution to these challenges by seamlessly transitioning your patterns into digital files.

Simply take a photo of your paper pattern, and our technology will instantly convert it into a digital file.

You can make changes to your patterns directly within the digital format, eliminating the need for physical alterations.

Audaces Pattern

For pattern makers looking for excellence, Audaces Pattern is the perfect solution. It ensures the pattern design reaches a new level of efficiency and precision.

With its versatile approach, it’s possible to develop high-quality patterns, regardless of complexity.

Refine every detail to perfection, ensuring that your creative vision translates into patterns. This advanced solution will assist you with all your pattern making endeavors!

Discover Audaces360 and unlock a world of possibilities for fashion design and production. Explore our comprehensive suite of solutions today!

FAQ

The fashion industry is moving faster than ever. Shorter deadlines and greater demand mean there’s less room for delays or errors. In this context, handmade patterns can slow things down.

The biggest difference is in the tools and the time. To create handmade patterns, you need paper, rulers, and pencils. Digital patterns only require a computer with specialized software.

Greater precision and consistency, faster processes, automatic grading, save time and resources.