Summary

- 3D CAD is transforming the way apparel businesses design and produce collections.

- It helps fashion companies cut costs, speed up development, and reduce waste.

- Want to dive deeper into 3D design? Get our exclusive guide now!

From digital prototyping to realistic simulations, 3D CAD offers tools that make fashion design more accurate and efficient. For business owners, it means fewer physical samples, faster approvals, and better collaboration between teams.

Understanding how to apply 3D CAD in your processes gives your brand a competitive edge. Whether you’re optimizing resources or creating innovative designs, this technology brings measurable results.

No matter the size of your fashion business, 3D CAD provides opportunities to grow smarter, faster, and more sustainably. Now, it’s time to explore these benefits in our article.

Happy reading!

Sumário

What is 3D CAD?

3D CAD stands for three-dimensional computer-aided design. It is software that allows designers and companies to create digital models of products on a computer.

Instead of drawing by hand or making early samples, you can build ideas directly in a virtual space.

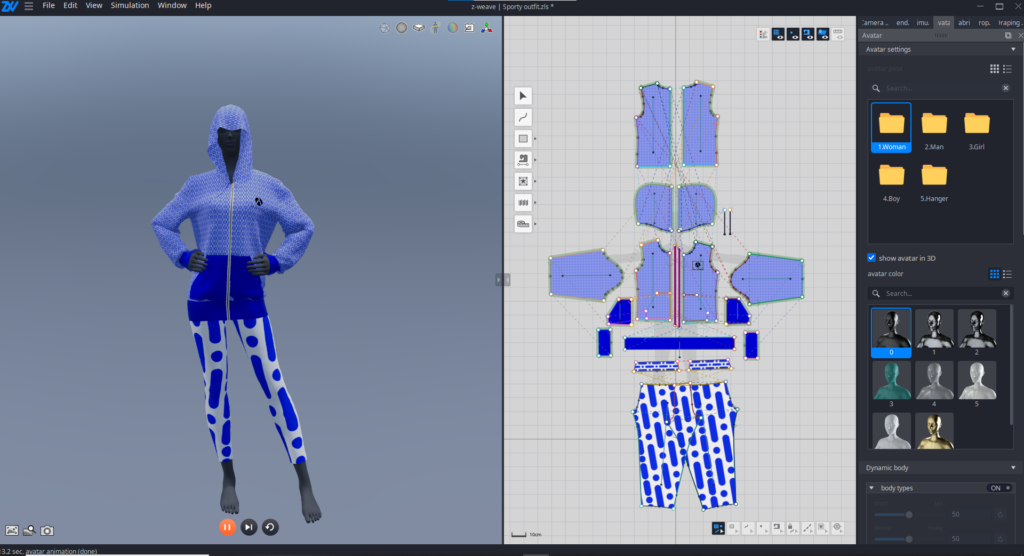

In fashion, 3D CAD helps bring garments to life before they exist physically. A designer can shape clothing on a screen, test how it looks, and make changes instantly. This makes the creative process faster and easier to control.

The technology also makes it possible to view a garment from every angle. You can see how it will move, fit, and behave with different fabrics. This improves accuracy compared to traditional sketches.

Overall, 3D CAD has become an essential tool for product development in fashion. It supports creativity, reduces mistakes, and allows businesses to move forward with more confidence.

How is 3D CAD used in fashion?

You can apply 3D CAD in several stages of fashion design and production.

Through this technology, designers can build virtual garments, create accurate patterns, and simulate fabrics or prints. Each step saves time and resources compared to traditional methods.

The next sections explain three of the main uses:

Virtual prototyping

The feature allows fashion designers to build garments digitally before making physical samples. This means you can test your ideas without cutting fabric or sewing.

With this method, you can experiment with different silhouettes, colors, and details quickly. It becomes easier to evaluate design options and share them with your team.

You can also place the digital garment on an avatar to see how it fits and moves. It’s the best way to reduce the need for multiple physical prototypes, saving time and money.

By combining virtual prototyping with 3D modeling, brands can shorten the design cycle and bring collections to market faster.

Pattern development

Pattern development is another area where 3D CAD makes a difference. Traditionally, professionals had to draw them by hand on paper. Now, it’s possible to create and adjust them directly on a computer.

This allows for precise measurements and quick changes. If you need to resize or alter a piece, you can do it instantly without redrawing everything.

You can also link digital patterns to virtual garments. This way, it’s easier to test the fit and look before producing a real sample.

Learn more: 5 reasons why pattern makers should start using 3D pattern

Print and fabric simulation

Simulation is one of the most exciting uses of 3D CAD. It allows designers to test different textiles, colors, and patterns on a digital garment. You can see how a fabric will drape, stretch, or shine under different lights.

Moreover, you can test prints in scale and position. For example, you can check if a floral pattern looks better centered or all-over before printing any fabric.

This simulation reduces waste and improves design decisions. It helps ensure that the final garment matches the creative vision from the very beginning.

Learn more: Discover the functionality and benefits of 3D fabric to fashion

Benefits of using 3D CAD in your fashion business

The benefits of using 3D CAD are clear. Designers, managers, and production teams all gain from smoother and more reliable processes.

Now, let’s explore six key benefits of using 3D CAD in your fashion business:

1) Cost reduction

One of the biggest advantages of 3D CAD is the ability to lower costs. By working digitally, you reduce the need for physical samples, fabric tests, and repeated adjustments.

This is because every sample made with real fabric has a cost. When you can test ideas on screen first, you cut back on these expenses.

3D CAD also helps avoid mistakes that lead to wasted material. Designers can check proportions, patterns, and prints virtually, ensuring accuracy before production begins.

In the long run, less waste and fewer errors mean more efficient use of resources.

Learn more: 5 benefits of 3D modeling software in your apparel company

2) Faster collection development

This is another key point, since speed is vital in fashion. Trends change quickly, and brands must respond fast to stay relevant.

Instead of waiting for physical samples, teams can create digital prototypes in hours with 3D CAD. It allows professionals to explore more options in less time. They can try different colors, fabrics, and shapes without starting from scratch.

By accelerating development, companies can launch collections sooner. This means reaching the market at the right moment and staying ahead of competitors.

Do you know how much time and fabric you waste making multiple samples for approval? Discover how to streamline your process with digital prototypes. Download our exclusive guide!

3) Fewer errors and rework

Mistakes in fashion production can be costly. Wrong measurements, poor fit, or misplaced prints often lead to rework. And 3D CAD plays a major role in reducing these risks.

With digital tools, patterns are precise and easy to adjust. Pattern makers can check fit and proportions on virtual garments before cutting any fabric.

Fabric simulation also helps spot issues early. If a textile looks too heavy or a print is out of alignment, they can fix the problem on screen. This accuracy lowers the chance of errors and avoids the need for multiple corrections. As a result, production runs more smoothly and reliably.

4) Better team communication

Designing a collection involves many people: designers, pattern makers, managers, and production staff. You can only imagine how a clear communication between them is important.

A great benefit is that 3D CAD provides a shared visual reference. Instead of trying to explain ideas with sketches or words, teams can look at the same digital garment. This makes discussions faster and more productive. Everyone can understand the design and give feedback in real time.

Stronger communication means less confusion and more teamwork, improving the entire process from design to production.

Learn more: Discover 5 major benefits of 3D simulation for fashion

5) Lower environmental impact

Sustainability is a growing priority in fashion. And 3D CAD supports this goal by reducing the need for physical samples and fabric waste. Every prototype that stays digital saves fabric, dye, and other resources, lowering the environmental footprint of a collection.

The technology also reduces transportation needs. This is because you can share samples digitally with teams or clients anywhere in the world.

By using fewer materials and generating less waste, companies can work in a more eco-friendly and responsible way.

6) Integration with automatic cutting and production

3D CAD does not stop at design. It connects with advanced production tools, such as automatic fabric cutting systems. Once you place your digital patterns in a marking, it’s possible to send it directly to cutting machines. This ensures precision and consistency in every piece.

Integration also eliminates manual steps, which saves time and reduces errors. The transition from design to production becomes smooth and reliable.

For companies that want efficiency, this link between 3D CAD and production technology is a powerful advantage. It helps scale operations while maintaining quality.

Learn more: Why simulate the 3D fit of garments before production?

How much does it cost to implement 3D CAD in your company?

The cost of implementing 3D CAD can vary depending on several factors. It is not a one-size-fits-all investment, since each fashion business has different needs and goals.

One factor is the size of your company. A small studio may need fewer licenses and simpler features. Meanwhile, a large manufacturer might require a complete package with advanced tools.

Another element is the integration with other systems. If you already use digital solutions, adding 3D CAD may be faster and more affordable. If you are starting from scratch, the investment could be higher.

To know the exact cost for your business, you can always contact an Audaces consultant. They will understand your company’s needs and suggest the best solutions for your company.

Learn more: What is the best 3D clothing design software to invest in?

Boost your fashion creations with Audaces 3D

Audaces 3D is the ideal solution for pattern makers to bring creations to life in a 3D simulation mannequin.

You can test your digital patterns before committing to a physical sample. This is your chance to check if all your patterns are successful or if they need any changes.

In fact, our platform allows you to approve your entire collection without a single physical sample!

With various tools and possibilities, this innovation transforms the creative and development processes. Experiment with designs featuring intricate elements and elevate your work to new heights.

Experience the freedom of shaping your ideas directly in a digital environment. This will add more agility and quality to your deliveries.

Discover Audaces360 and unlock a world of possibilities for pattern development. Explore our comprehensive suite of solutions today!

FAQ

3D CAD stands for three-dimensional computer-aided design. It is software that allows designers and companies to create digital models of products on a computer.

The uses include virtual prototyping, pattern development, and print and fabric simulation.

Some of the benefits are cost reduction, faster collection development, better team communication, and lower environmental impact.