Summary

- In the world of fashion, getting the right fit is the first step to a successful collection.

- This can be a challenge for pattern makers using traditional, time-consuming methods.

- Simplify your fashion development process with Audaces360 solutions. Sign up for your free trial today!

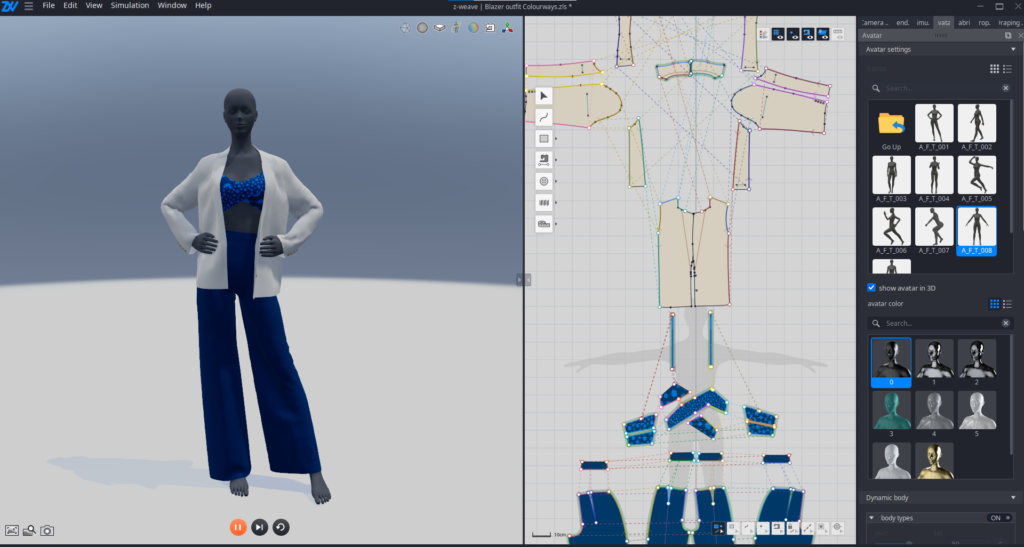

As technology evolves, new solutions are becoming available. One of these tools is 3D fit simulation. It allows pattern makers to test digital models of garments.

You can see how a piece will fit before making it in real life. It’s an easy way to identify potential issues, saving time and resources.

Let’s explore the benefits of this game-changing technology. We’ll walk you through how to use it to transform your work.

Enjoy your reading!

Sumário

Why simulate 3D fit before producing your garments?

Simulating 3D fit before producing garments is a smart move. First, it saves time and money.

By using digital models, pattern makers can spot fit issues early. It reduces the need for physical samples. As a result, the use of resources is more efficient.

3D simulations also allow for more creativity. You can experiment with different details quickly. It’s possible to see how changes affect the design without wasting materials.

This flexibility results in better garments and satisfied customers. Ultimately, it streamlines the process and enhances the final product.

Learn more: Learn what 3D modeling is and its benefits for clothing design and production

How to make fit adjustments in a 3D model?

Making fit adjustments in a 3D model involves a step-by-step process. Each step helps ensure the garment fits perfectly before production.

Let’s explore them steps in detail:

Choose the desired avatar

The first step is to choose the right avatar. You can select from various genres and body types. This allows you to tailor your design for different customers.

Using the right avatar helps you visualize how the garment will fit. It ensures your design looks good on different body shapes.

This way, you can create styles that work for everyone, making them more comprehensive. For creating pet clothing patterns, for example, you can select this type of avatar.

Learn more: Explore the fashion future demands and anticipate what’s next in the market

Check the garment’s proportions and measurements

Next, check the garment’s proportions and measurements. Look closely at how the garment fits the chosen avatar.

Evaluate if the sizes are accurate. You can also assess the overall look and ensure it aligns with the design goals.

It allows you to ensure the garment looks consistent from all angles. This attention to detail helps in creating a polished final product.

Learn more: 5 reasons why pattern makers should start using 3D pattern

Add or reduce volume

After checking proportions, you may need to add or reduce volume. This is important for achieving the right fit.

If there’s excess fabric, it can make the garment look bulky. By adjusting the volume, you can create a sleeker silhouette.

Reducing volume can also enhance comfort. A well-fitted garment allows for easier movement. It’s essential to balance style with wearability.

Remember, small adjustments can make a significant difference in how a garment looks.

Learn more: 4 mistakes you should avoid in clothing fit

Simulate the fabric’s drape

Once you’ve adjusted the volume, it’s time to simulate the fabric’s drape. This step gives you a detailed view of how the material behaves.

Fabric simulation allows you to experiment with different materials and textures. It’s possible to select the fabric that best fits the desired look of the final product.

You can see how it flows and falls on the avatar in a realistic way. It helps you visualize real-life scenarios. This allows you to observe how the fabric reacts to movement.

Learn more: Discover the functionality and benefits of 3D fabric to fashion

Assess the garment in motion

Finally, assess the garment in motion by simulating real-world conditions. It shows how the garment performs while walking or bending, for example.

Observing the fit during movement is important to ensure comfort and style. This assessment helps identify any issues that may arise. You can make changes based on how the garment behaves.

Many times, these potential pattern-making mistakes are overlooked, even with a physical prototype. It’s only through everyday wear that you can truly determine a garment’s comfort.

This is where 3D fit software excels, as it simulates movements to guarantee the optimal fit.

Discover how technology can streamline your work! Download our free e-book to learn how to design in a smart and sustainable way:

Benefits of adjusting 3D models before production

Adjusting 3D fit before production offers many benefits. These advantages help streamline the development process and improve final outcomes. Find out more:

Faster production

One major benefit is faster production. By making adjustments in 3D, pattern makers can quickly identify fit issues.

This reduces the time spent on physical samples. With fewer prototypes needed, the entire process speeds up.

In addition, faster production means quicker turnaround times. Brands can bring their products to market sooner.

It’s especially important in the fast-paced fashion industry. Speed can give companies a competitive edge.

Learn more: 5 benefits of 3D modeling software in your apparel company

Reduced costs

Another significant benefit is the reduction in costs. Fewer physical samples mean lower material expenses. These savings can mean a lot for businesses trying to stay profitable.

Moreover, by spotting problems early, brands avoid costly mistakes. Fixing issues in a digital model is cheaper than correcting them after production.

Identifying pattern problems after production is a costly mistake. It can lead to the scrapping of entire fabric batches. This incurs significant financial losses and production delays.

Less material waste

Adjusting 3D fit also leads to less material waste. When issues are resolved digitally, there’s less need for extra fabric. It results in fewer scraps and unused materials.

Reducing waste is not only good for business, but it’s also better for the environment.

Companies can showcase their commitment to sustainability. This can attract customers who value eco-friendly practices.

This approach is becoming more and more prevalent in the fashion industry. You can even leverage your sustainable initiatives in campaigns to capture your audience.

Learn more: Find out how fast fashion and sustainability can coexist in the apparel industry

360-degree view

Having a 360-degree view of the garment is another advantage. This perspective allows professionals to see every angle of the model. It helps assess how the garment fits and flows.

With this view, it’s easier to spot details that may need refinement. You can ensure that the garment looks great from all sides.

This comprehensive look enhances quality control, minimizing the chances of oversight.

It’s especially important for garments with intricate details. Inspect cutouts, pleats, and ruffles to guarantee a flawless finish to the design.

Learn more: What is the best 3D design software to invest in?

Easier team collaboration

Finally, adjusting 3D models makes team collaboration easier. Pattern makers can share their work digitally with others. This allows for instant feedback and quicker decision-making.

Teams can work together seamlessly, even if they are in different locations. Everyone can access the same model, making communication clearer.

A major benefit of digital pattern making is the secure file-saving system. It ensures that even with multiple users, the most recent version of the file is always correct.

Collaboration helps create a better end product that meets everyone’s expectations.

Learn more: Why invest in collaborative creation in fashion business?

Use Audaces 3D fit simulation to boost the profitability of your collection

Audaces Pattern

For pattern makers looking for excellence, Audaces Pattern is the perfect solution. It ensures the pattern design reaches a new level of efficiency and precision.

With its versatile approach, it’s possible to develop high-quality patterns, regardless of complexity.

Refine every detail to perfection, ensuring that your creative vision translates into patterns. This advanced solution will assist you with all your pattern making endeavors!

Audaces 3D

Audaces 3D is the perfect complement to Audaces Pattern. You can test your digital pattern before committing to a physical sample.

Save time and resources by assessing the 3D fit. Identify issues early in the process to avoid delays and rework.

With a range of tools and possibilities, this software transforms the development processes. It enables you to shape your ideas in a digital space, gaining agility and quality in deliveries.

Discover Audaces360 and unlock a world of possibilities for fashion design and production. Explore our comprehensive suite of solutions today!

FAQ

By using digital models, pattern makers can spot fit issues early. It reduces the need for physical samples. As a result, the use of resources is more efficient.

Choose the desired avatar, check the garment’s proportions and measurements, add or reduce volume, simulate the fabric’s drape, and assess the garment in motion.

Faster production, reduced costs, less material waste, 360-degree view, and easier team collaboration.