Summary:

- 3D fabric is produced using additive manufacturing techniques such as 3D printing;

- The three-dimensional structure is built up in successive layers;

- Enhance production management with Audaces360 multi-solution. Sign up for the free trial now!

The fashion industry is experiencing continuous revolution thanks to technological advancements, resulting in more sustainable and efficient garment production.

Among these innovations, 3D fabric stands out as a powerful tool that bridges the gap between the physical and digital realms.

Renowned as one of the most groundbreaking techniques in the textile sector, 3D fabric offers numerous advantages for production processes.

If you’re interested in delving deeper into this fabric’s capabilities, we invite you to explore the following text.

Sumário

Enjoy your reading!

What is 3D fabric?

3D fabric represents a remarkable advancement in textile production, achieved through additive manufacturing techniques like 3D printing.

This innovative process enables the creation of intricate and personalized three-dimensional fabrics with unique structures.

Unlike traditional flat textiles, the 3D fabric is built layer by layer, allowing for the incorporation of diverse properties such as elasticity, rigidity, or flexibility, tailored to meet the specific requirements of the final product.

The applications of 3D fabric are vast, encompassing the creation of distinctive designs for clothing and accessories, while simultaneously offering enhanced comfort and performance benefits.

Although still in the developmental phase, the technology behind 3D fabric showcases immense potential to revolutionize the industry, providing solutions for a wide array of applications.

Learn more: Find out how futuristic fashion is revolutionizing the industry with technology

How does 3D fabric work?

3D fabric operates on the principles of additive manufacturing, with techniques like 3D printing at its core.

This intricate process involves layering materials with a predefined three-dimensional design, ultimately yielding a structure with distinct properties.

The selection of materials utilized in the printing process significantly impacts the outcome of the 3D fabric, spanning from plastics to biocompatible and even biomaterials, tailored to specific applications.

Typically, the process encompasses the following steps:

Design

The initial step involves creating the 3D fabric design using specialized fashion design software. During this stage, the structure and desired physical characteristics of the fabric, such as density, elasticity, and stiffness, can be meticulously crafted.

File preparation

Next, the design is prepared for 3D printing by converting it into a suitable file format.

This process may entail segmenting the model into thin layers and generating a file in formats such as STL (Standard Tessellation Language) or OBJ (Object File).

These formats ensure compatibility and accurate representation during the printing process.

3D printing

The prepared file is utilized as input for a 3D printer, which proceeds to construct the fabric by depositing or solidifying the material layer by layer, adhering closely to the design specifications.

Various 3D printing technologies can be employed, such as Fused Material Deposition (FDM) and Stereolithography (SLA), each offering distinct advantages and characteristics.

Post-processing

Following the completion of the 3D printing process, additional post-processing steps may be necessary to refine the fabric’s quality and appearance.

These steps encompass the removal of support structures, thorough cleaning of the fabric, surface finishing techniques, and optional treatments to enhance fabric properties, such as dyeing or the application of specialized coatings.

These post-processing procedures contribute to optimizing the final fabric’s aesthetics and performance.

Learn more: What 3D modeling is and its benefits for clothing design and production

Example of products with 3D fabric

As 3D fabric technology continues to advance, innovative designers are pushing the boundaries of its application in various garments and accessories.

Let’s explore a few examples of fashion products that can be created using 3D fabric:

Dresses

Dresses with 3D fabric boast captivating textures and patterns that produce a mesmerizing three-dimensional effect.

These garments can incorporate voluminous or structured details, elevating the overall aesthetic with a touch of modern elegance.

Skirts

Skirts crafted from 3D fabric might feature pleats or ruffles that generate a visually striking layered effect.

These skirts infuse volume and dynamic movement into any ensemble, positioning them as essential staples within a fashion-forward wardrobe.

Blouses

Blouses crafted from 3D fabric can be adorned with exquisite, embossed details or textured patterns that bestow a sophisticated and unparalleled aesthetic.

These versatile blouses effortlessly transition between formal and informal occasions, infusing each ensemble with a touch of individual style.

Coats

Coats fashioned from 3D fabric showcase geometric or structured patterns that exude a futuristic charm.

These jackets are perfect for enhancing any winter ensemble, adding a fashionable edge to your outerwear collection.

Shoes

Some designers explore 3D fabric in footwear, creating items with different textures.

Shoes crafted from 3D fabric can showcase intricately carved patterns or even incorporate embossed elements, imparting a truly distinctive and eye-catching aesthetic

The benefits of incorporating 3D fabric in fashion

The integration of 3D fabric in fashion apparel unlocks a wide range of advantages for designers, manufacturers, and consumers alike.

Below are some of them:

Innovative design

Utilizing 3D fabric empowers designers to forge fashion pieces adorned with captivating three-dimensional textures and patterns.

Moreover, it grants them the freedom to venture into uncharted territory, exploring innovative shapes and styles that culminate in truly exceptional and imaginative creations.

Improved fit and comfort

Renowned for its elasticity and adaptability, 3D fabric delivers an exceptional fit by conforming to the body’s curves, resulting in a precise and tailored experience.

Furthermore, its three-dimensional structure provides elevated comfort levels by facilitating improved ventilation and breathability, ensuring a pleasant and breathable wearing experience.

Sustainability

Embracing 3D fabric production represents a step towards sustainability compared to conventional fabrics.

The utilization of low environmental impact techniques like 3D printing minimizes material waste throughout the manufacturing process.

Besides, the inherent durability and longevity of 3D fabric contribute to the reduction of garment waste, fostering a more sustainable approach within the fashion industry.

Learn more: Why consider sustainable consumption and production for your company?

Versatility

The versatility of 3D fabric knows no bounds, as it finds application in clothing, footwear, accessories, and even architectural or decorative elements.

This adaptability enables designers to explore an expansive array of shapes, textures, and properties, expanding the design and functionality options of their products to unprecedented levels.

Production and cost efficiency

Leveraging 3D fabric can yield significant advantages in terms of production time and cost-effectiveness.

Techniques like 3D printing enable the creation of custom fabrics on demand, eliminating the need for excessive inventory and reducing wastage.

Additionally, the use of 3D fabric simplifies the manufacturing process by reducing the number of steps and minimizing the complexity of sewing and finishing requirements, resulting in streamlined production and potential cost savings.

Audaces technologies provide 3D fabric simulation

In the pursuit of delivering exceptional results, leveraging technology proves to be the optimal solution.

Audaces proudly presents cutting-edge solutions that integrate every stage, from design to production.

Discover how Audaces empowers your business to achieve the best outcomes:

Audaces Fashion Studio

Discover Audaces Fashion Studio, an innovative solution that enables designers to develop both physical and virtual clothing.

This revolutionary software redefines visual communication, expediting model approvals and harmonizing the present and future of the fashion market within a single tool.

Unlock a world of possibilities with Audaces Fashion Studio, providing an extensive range of resources, including:

- Witness the behavior of garments before physically producing them through advanced simulations. This ensures an accurate result while saving time and materials;

- Experiment with various combinations and gain a faithful representation of your designs. That facilitates informed decisions on the best options;

- Experience enhanced efficiency during the creation phase as the software reduces the need for multiple sample productions;

- Easily transition from design to production with the aid of Audaces Fashion Studio. Once a design is approved within the software, effortlessly create models, enabling a smooth transition between these crucial stages;

- Promote effective communication between the Style and Modeling teams, minimizing errors and unnecessary rework;

- View and make precise adjustments directly on the computer screen, guaranteeing high-quality results.

And that’s just the beginning! Audaces Fashion Studio offers an array of features designed to elevate creativity and efficiency in the fashion industry.

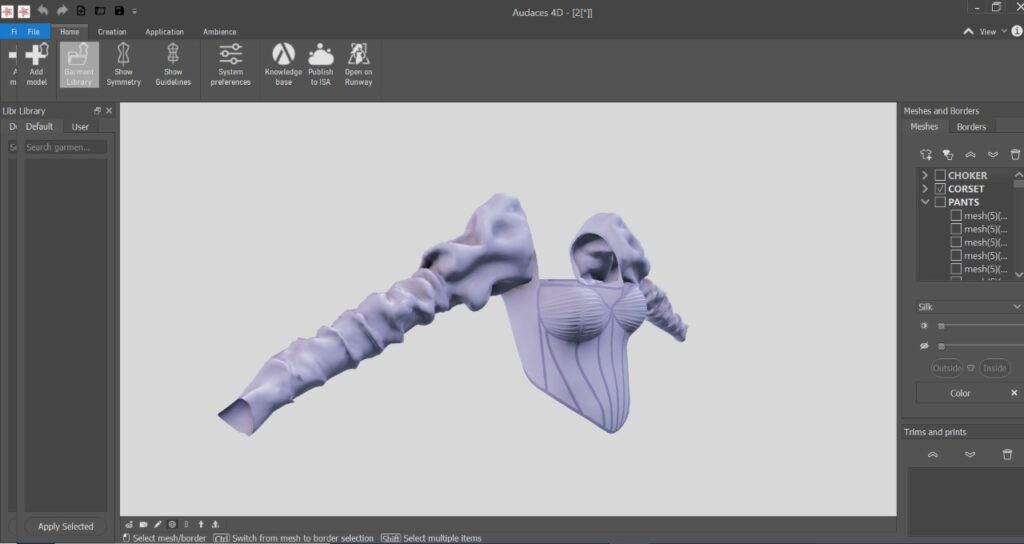

Audaces 3D

Imagine software that revolutionizes fashion design by enabling the creation of three-dimensional models on virtual mannequins, offering a wealth of tools — that’s Audaces 3D.

With this innovative solution, you can bid farewell to the traditional method of creating paper templates, saving valuable time and resources. Elevate your professional prowess and embrace the technology of Industry 4.0 with Audaces.

With our software, you can effortlessly confirm the fit and appearance of garments by simulating their look on a virtual model.

Also, you actively contribute to a more sustainable process, as it reduces paper consumption and minimizes environmental impact.

One of the standout advantages of Audaces 3D is its ability to render realistic images. Create high-quality visuals for marketing and sales purposes, captivating audiences with enticing presentations of your fashion projects.

To enhance the customer experience, we still offer an online fitting room feature. Customers can virtually try on garments and preview how they would look on their own bodies before making a purchase.

With Audaces 3D, you gain access to all the essential tools needed to create, test, and promote your fashion creations!

Now that you have gained insight into the significance of 3D design in the fashion industry, how about uncover the importance of choosing the right textiles for your production?

Download our free e-book today to find out more about all the different types of fabrics:

FAQ

It encompasses a category of textiles created through additive manufacturing methods like 3D printing. It involves layering materials to form intricate three-dimensional structures with distinct properties and characteristics.

By combining layers of material based on a 3D design, the result is a fabric with specific properties tailored to meet desired requirements. This innovative manufacturing process opens new possibilities for creating textiles.

Its versatiçity allows for the creation of a wide range of fashion products. From dresses and blouses to pants, skirts, and coats, designers can explore unique textures, patterns, and shapes. Additionally, it can be utilized in the production of footwear and accessories like bags and jewelry.