Summary:

- A pattern grading chart is employed to scale up or down a foundation pattern;

- You can use the pattern grading chart to grade garments for various sizes;

- Optimize your business efficiency with Audaces360 multi-solution! Get the free trial now and see how to manage each stage of your production!

A pattern grading chart is an excellent tool for garment modelers, offering several benefits that can enhance their work.

This technique not only brings a higher level of precision to the pieces created but also instills confidence in the entire production process.

If you’re willing to explore the advantages of utilizing the pattern grading chart in your daily fashion business operations, you’ve come to the perfect blog post!

In the following sections, we delve into this resource that lies at the heart of scaling up the production of your garments while maintaining quality.

Sumário

Welcome and enjoy reading!

What is a pattern grading chart?

A pattern grading chart is an essential tool used in the fashion industry to proportionally adjust a foundation pattern, enabling the creation of garments in different sizes.

This process involves gradually increasing or decreasing the measurements of the foundation pattern to generate patterns corresponding to various sizes.

The chart incorporates crucial measurements like bust, waist, hips, length, and more. It also provides a correlation of measurements for each mannequin, simplifying the mathematical calculations involved in grading a model.

By utilizing this table, fashion companies can produce clothing in a wide range of sizes, effectively catering to the needs of their customers. It plays an important role in the large-scale manufacturing process, ensuring the availability of diverse garment sizes.

Learn more: How to incorporate digital patterns into your production

How to make a pattern grading?

Pattern grading is a skill that requires expertise in pattern making. Here’s a simplified guide to help you navigate the process:

Modify the base pattern

Begin with a pattern block, representing the desired standard size for grading.

Transfer this template onto kraft paper or utilize digital modeling software, ensuring accurate measurements and markings.

Learn more: What digital sketching is and how to apply it to your fashion collection

Estabilish the size grid

Define the range of sizes to which you will grade the pattern. This can encompass a variety of sizes, either from smallest to largest, or based on your target audience.

Determine the size grid according to industry standards or your brand’s specifications.

Adjust key points

Add or remove points along the base pattern to achieve different sizes.

Focus on critical areas such as the bust, waist, hips, and length.

Utilize the pattern grading chart to determine precise increments or reductions for each stitch, corresponding to the size grid.

Trace the grading lines

When manually grading, use a straightedge or a French curve to draw smooth lines that connect the added or removed points.

Alternatively, with a reliable digital modeling system, simply include or exclude the points and adjust their curvature accordingly.

Ensure that the grading lines follow a logical pattern, preserving the shape and proportion of the base pattern as you scale it up or down.

Verify and refine

Once the grading lines are in place, carefully check that all measurements are accurate.

Make necessary adjustments to achieve a proper and visually appealing fit for each size in the grid.

This step ensures consistency and maintains the desired quality across all graded patterns.

Learn more: When to use each modeling technique and how to choose them wisely

Advantages of using a pattern grading chart

A pattern grading table offers numerous advantages for efficient garment production across different sizes, guaranteeing a proper fit and preserving aesthetic appeal.

By leveraging this tool, you can enhance your scale production capabilities and ultimately increase customer satisfaction. Below are the key gains for your fashion business:

Accuracy and consistency

The pattern grading chart offers a systematic and standardized approach to resizing your base pattern.

This ensures precise and consistent size changes, resulting in properly fitting garments across all sizes.

Learn more: What 3D modeling is and its benefits for clothing design and production

Time and effort savings

By utilizing the pattern grading table, pattern makers are spared from the need to completely redesign patterns for each size.

Instead, they can follow the instructions provided in the chart, saving valuable time and effort in creating individual patterns.

Learn more: What digital sketching is and how to apply it to your fashion collection

Greater efficiency in scale production

The pattern grading chart facilitates the efficient production of garments in various sizes.

By easily scaling up or down the base pattern, larger batches of garments can be produced more efficiently, reducing production time and increasing productivity.

Learn more: How can fashion brands boost their business with technology?

Aesthetic consistency

The pattern grading chart ensures that the aesthetic pattern of garment parts remains consistent across different sizes.

This means that design details, proportions, and visual characteristics are preserved, maintaining the brand identity and desired appearance of the garments.

Learn more: How digital fashion design works and what are the benefits for the clothing industry

Adaptability to market trends

The pattern grading table enables fashion companies to swiftly respond to trends and emerging market demands.

By referring to the information in the chart, it becomes possible to create patterns for new sizes or adjust proportions accordingly. This flexibility allows for agile adaptation to changing fashion trends and customer preferences.

Streamline your pattern grading process with Audaces

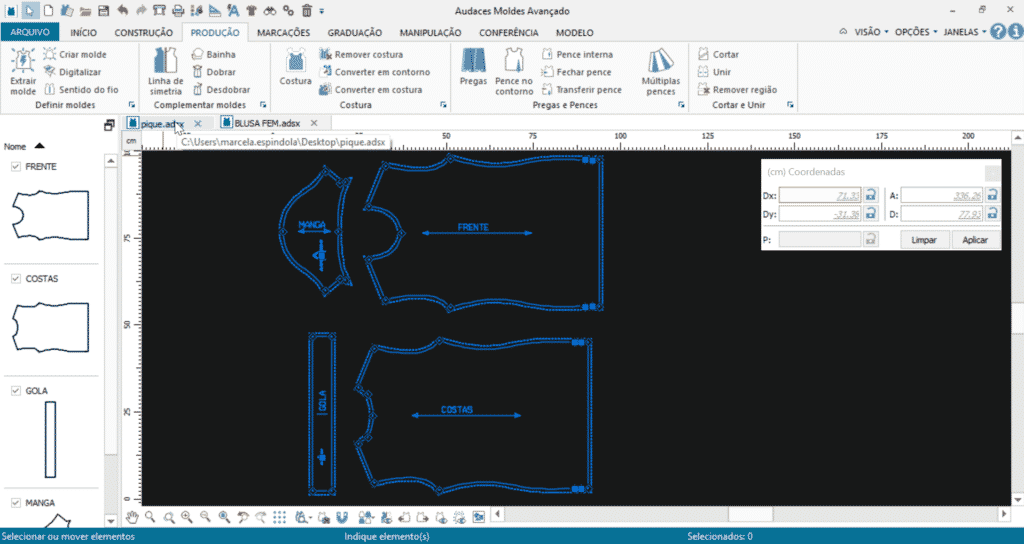

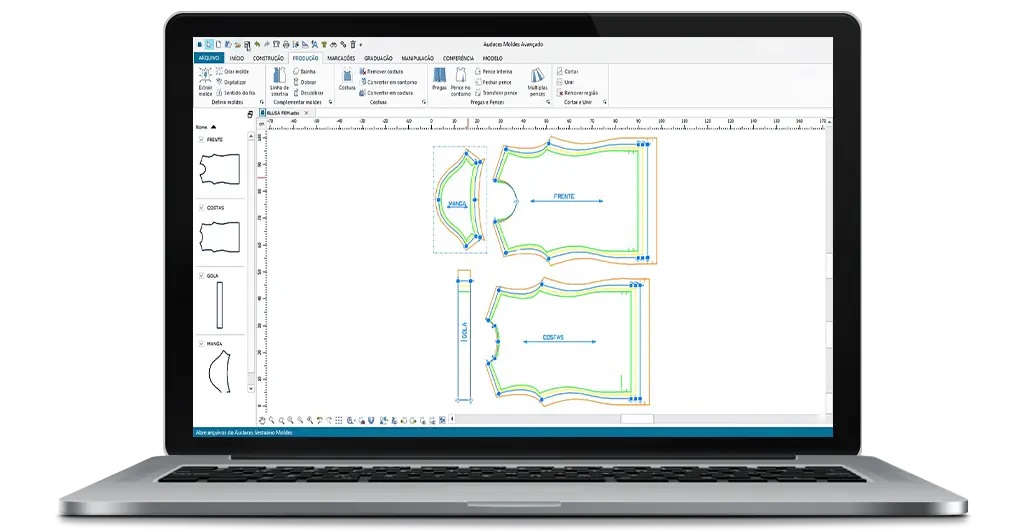

Accelerate your foundation grading process with Audaces Pattern, an advanced software designed to simplify digital pattern creation. Discover its key features next:

Intuitive interface

Audaces Pattern boasts a user-friendly interface that speeds up the pattern creation workflow. Its intuitive design ensures a more efficient grading process.

Template library

Access a comprehensive library of pre-configured templates that serve as a starting point for creating new designs. This collection accelerates the process, saving valuable time and effort for pattern makers.

Drawing tools

Audaces Pattern offers an array of drawing tools, including lines, curves, arcs, and more.

These tools empower pattern makers to create precise and symmetrical shapes, ensuring impeccable accuracy.

Personalized measurement grid

Create custom measurement grids within the software, enabling the development of digital molds with different proportions.

Measurements can be directly entered or imported from other software, providing flexibility and adaptability.

Automatic error-checking

Benefit from Audaces Pattern’s automatic error checking tool, which detects and flags issues within the molds.

Whether it’s identifying overlaps, intersections, or other inconsistencies, this feature ensures that patterns are error-free before printing or production.

Integration with other tools

Audaces Pattern seamlessly integrates with other Audaces360 multi-solution tools, including Audaces Marker, to deliver a comprehensive mold modeling, fitting, and grading solution.

This integration enhances efficiency and accuracy, providing industry professionals with a complete and streamlined workflow.

Download our complimentary e-book for free and unlock the full potential of Audaces technology in achieving accurate patterns digitally:

FAQ

A pattern grading chart is a valuable tool utilized in the fashion industry to proportionally scale a base pattern, enabling the creation of different sizes for garments.

To perform pattern grading, redraw your base pattern; set up a size grid; add or remove points along the base pattern; and trace gradation lines to connect the points.

By leveraging the benefits of a pattern grading chart, you can achieve accurate sizing, save time and effort, improve production efficiency, maintain design consistency, and adapt to changing market trends effectively.