Summary:

- Digital patterns are virtual files that encompass every detail of a piece of garment to be produced;

- This type of pattern is usually created with 3D modeling software;

- Revolutionize your clothing production with Audaces360 multi-solution and manage every stage with ease. Get the free trial today!

Pattern creation is a meticulous process that requires precision, but in today’s digital age, there are simpler and more efficient methods available.

With new challenges arising and customer demands increasing, optimizing time, minimizing errors, and embracing sustainability have become crucial in the fashion industry.

If you’re willing to integrate digital patterns into your clothing production workflow, it’s essential to comprehend their functionality, and benefits, and select the ideal system for your company’s needs.

We hope you enjoy this article!

Sumário

What is a digital pattern?

A digital pattern is an online file containing precise measurements and shapes required for creating a garment.

It is generated using advanced 3D modeling software, enabling fashion professionals to develop clothing styles and make necessary adjustments with precision.

By utilizing a digital pattern, the entire creation and production process becomes remarkably efficient.

Designers and pattern makers gain the ability to visualize the final product before physically producing it, facilitating swift and accurate adjustments.

Moreover, digital patterns offer more collaboration as they can be easily shared with different teams and manufacturers.

That fosters streamlined communication and facilitates large-scale production, ensuring a smoother workflow.

Another significant advantage of digital patterns lies in their sustainability benefits, by reducing the reliance on paper and minimizing waste associated with traditional pattern creation.

Furthermore, digital patterns promote on-demand production, effectively minimizing material waste and preventing excessive stockpiling of garment pieces.

Learn more: What digital sketching is and how to apply it to your fashion collection

Why should clothing companies invest in digital patterns?

Investing in digital patterns offers numerous benefits for apparel companies, enhancing efficiency, resource optimization, and overall productivity.

Explore the compelling reasons why embracing digital patterns is crucial in today’s fashion industry:

Streamlined time management

Digital patterns enable a more efficient workflow, optimizing the creation and production processes.

By utilizing digital patterns, clothing companies can accelerate their production timelines, ensuring faster and more accurate manufacturing.

This time optimization boosts overall productivity and contributes to meeting customer demands promptly.

Minimized errors

Digital patterns significantly reduce the risk of measurement errors during garment production.

This reduction in errors not only improves the quality of the final product but also minimizes material waste and the need for costly rework.

Sustainability

Investing in digital patterns aligns with sustainable practices, as it significantly reduces paper waste associated with traditional pattern-making techniques and enables on-demand production.

This eco-conscious approach resonates with consumers increasingly valuing sustainability.

Flexibility

Digital patterns bring more flexibility to your production process, empowering your business to adapt swiftly to customer requests and market demands.

They provide your business with more to respond quickly to changes.

Besides, with the facility to visualize and adjust garments digitally, designers can experiment more with various styles, shapes, and sizes, opening new avenues for brand differentiation.

Communication

Digital patterns enable agile collaboration among designers, pattern makers, and manufacturers.

With electronic files that can be easily shared, multilple teams can work together in real-time, regardless of their geographical location, taking communication and collaboration among them to another level!

Accuracy in measurements

The millimeter precision offered by digital patterns leaves traditional paper modeling methods behind. By employing them in your production, there’s no need for manual measurements and estimations.

The accuracy of digital patterns also minimizes production flaws, enabling precise adjustments prior to project initiation – which results in smooth execution while mitigating the costs associated with errors and the need for rework.

Learn more: Learn when to use each modeling technique and how to choose them wisely

How to incorporate digital patterns into your production?

To incorporate digital patterns into your garment production, there are several essential steps to follow.

One of the initial requirements is to obtain reliable modeling software, as numerous options are available on the market.

Therefore, you must choose software that aligns with your manufacturing needs and has the necessary features for creating precise and realistic models.

Once you have the modeling program, you can proceed to generate a digital pattern. This can be accomplished either by adapting an existing model or design or by starting from scratch to create an entirely new style.

It is imperative that the digital pattern includes all the essential information required to accurately produce the garment, such as measurements, shapes, and seams, among others.

Prior to utilizing the digital pattern in large-scale production, it is essential to conduct thorough testing to ensure its correctness and compliance with all specifications. That can be performed by producing a scaled-down physical version of the garment or by examining a 3D representation.

After the digital pattern is created and tested, it can be integrated into your garment production process.

It is important for your employees to be acquainted with the utilization of the digital pattern or undergo appropriate training to effectively work with it.

And keep in mind that, to ensure the digital pattern’s accessibility and safekeeping for future use, it should be stored in a secure location, such as the cloud. So, it’s prudent to maintain a backup copy to mitigate the risk of data loss or technical issues.

By following these steps, you can successfully incorporate the digital pattern into your garment production and reap the numerous benefits it offers.

Learn more: Learn what 3D modeling is and its benefits for clothing design and production

Rely on Audaces technologies for your digital pattern creation

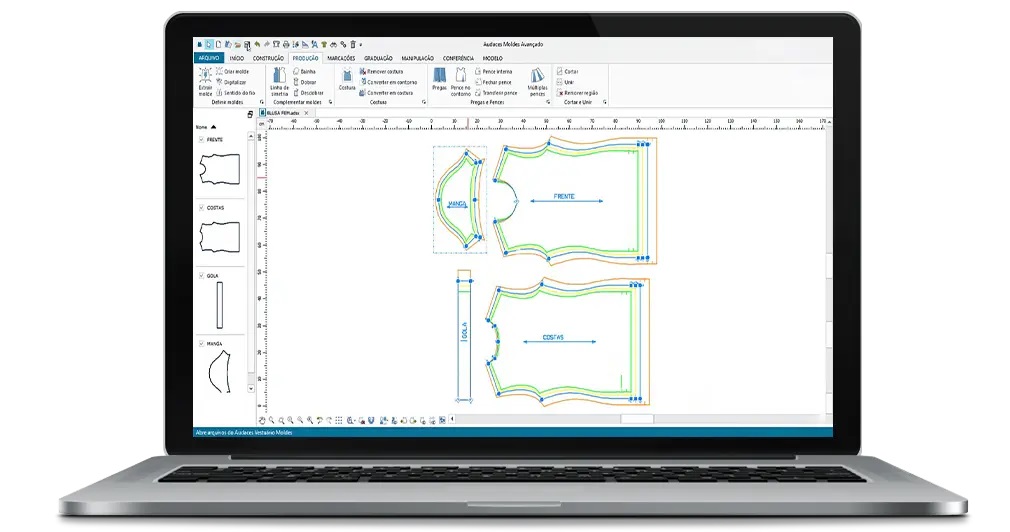

Audaces technologies provide comprehensive software solutions designed for pattern designing, marking, grading, and plotting digital fashion patterns.

These powerful tools offer a wide range of features and benefits that facilitate the creation and management of digital patterns in your manufacturing process, including:

Audaces Pattern

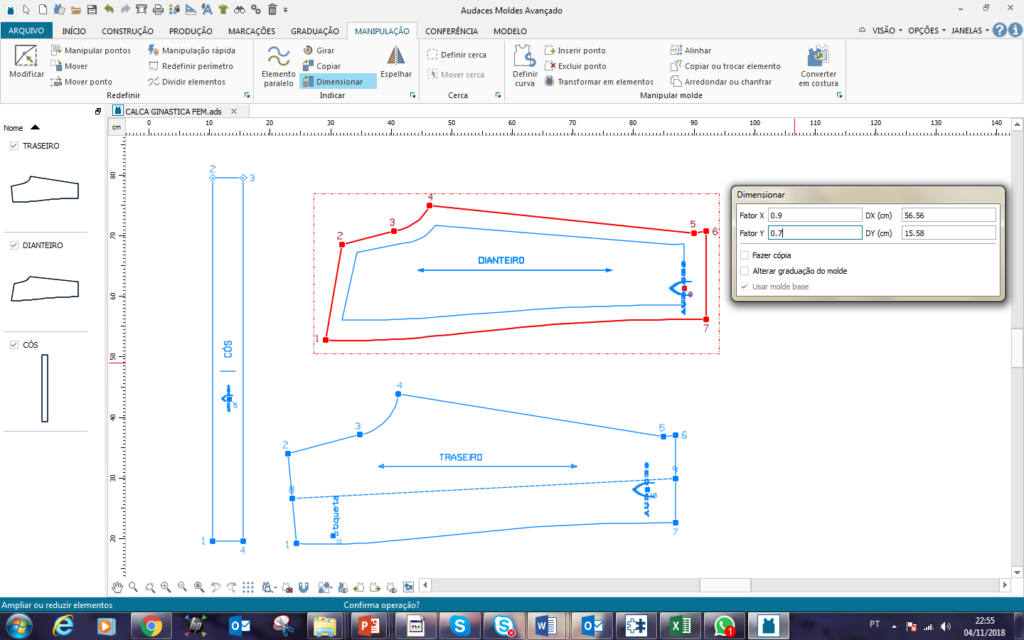

Audaces Pattern is an efficient and precise modeling software designed to streamline the process of creating digital patterns. It encompasses several resources that facilitate pattern creation, including:

Intuitive user interface

With its user-friendly interface, Audaces Pattern offers an intuitive platform that simplifies and accelerates the pattern creation process.

Template library

The software provides a library of pre-configured templates, serving as a foundation for creating new templates. This feature enhances efficiency by saving valuable time and effort.

Drawing tools

It also offers a diverse set of drawing tools, such as lines, curves, and arcs, enabling you to create digital patterns from scratch.

With these precise and symmetrical shapes, you can ensure the perfect accuracy of your patterns.

Measurement grid

By utilizing Audaces Pattern, you can establish a customized measurement grid that allows you to create digital patterns with various sizes and proportions.

This grid enables you to input measurements directly or import them from other software.

Automatic error-checking

The program also features an automated error-checking tool that promptly identifies issues within the patterns, such as overlaps, intersections, and other inconsistencies.

That guarantees the pattern’s accuracy prior to printing or direct implementation in the production process.

Integration with other tools

Audaces Pattern integrates with other powerful tools within the Audaces360 multi-solution suite, including Audaces Marker.

This integration offers a complete solution for pattern making, marking, and grading, ensuring optimal efficiency.

Audaces 3D

Audaces 3D is an advanced three-dimensional modeling software that allows you to visualize your clothing creations virtually, even before entering the production stage. This includes digital patterns, bringing your designs to life in a virtual environment.

This tool offers numerous capabilities to enhance the creation of patterns with top accuracy. Explore them below:

Garment modeling

Audaces 3D enables the creation of three-dimensional clothing pieces with a wide variety of options – ranging from basic garments like T-shirts, skirts, and pants to intricate styles such as bridal gowns and coats.

Real-time adjustments

From resizing and altering lengths to modifying formats and other settings, Audaces 3D allows you to fine-tune your digital patterns.

This ensures precise and customizable results that align with your desired specifications.

Digital template creation

Generate digital patterns directly from 3D models. Audaces 3D enables you to create digital templates swiftly, automating the process by leveraging existing modeled pieces.

Export to Audaces Pattern

Audaces 3D provides the capability to export your created digital patterns to Audaces Moldes, ensuring the accuracy and production readiness of the patterns generated from the 3D models.

Fabric and print simulation

It is possible to simulate fabrics and prints in real time. This enables you to visualize how different fabrics will appear in the final garment,

Interested in gaining a comprehensive understanding of how digital modeling works within the Audaces system? Then download our free e-book now for an in-depth exploration of this technology!

FAQ

A digital pattern is a file that contains precise information, including measurements and shapes, required for producing a garment. Unlike traditional paper patterns, digital patterns are created and stored digitally.

Digital patterns are easier to work with, optimizing resources and saving time. Additionally, these types of patterns contribute to sustainability efforts by reducing paper waste. They also provide greater accuracy and precision in pattern creation and enable seamless team communication.

Start by purchasing modeling software. It is essential to select software that aligns with your company’s needs and offers the necessary features for creating accurate and realistic models.