Summary

- The textile industry in India is one of the largest and most dynamic in the world.

- It combines tradition, innovation, and massive production capacity.

- Want fresh fashion news straight to your inbox? Subscribe to our newsletter!

Combining centuries-old techniques with high-tech textile manufacturing, India became a key player in global fashion. Its production covers everything from cotton and silk to synthetic fibers, serving domestic and international markets.

For fashion business owners, understanding India’s textile ecosystem means discovering new opportunities. The country’s skilled workforce, competitive costs, and growing sustainability initiatives make it a strategic choice.

No matter if you’re exploring new suppliers, planning a collection, or expanding your brand’s reach. The textile industry in India can be a valuable ally in your journey.

Happy reading!

Sumário

What is the impact of the textile industry in India?

The textile industry is essential for India’s economy. It contributes significantly to the country’s GDP and holds a strong position in exports.

The textile sector goes beyond clothing, including fabrics, home textiles, and industrial textiles. Its reach extends from small local workshops to large manufacturing units that supply global brands.

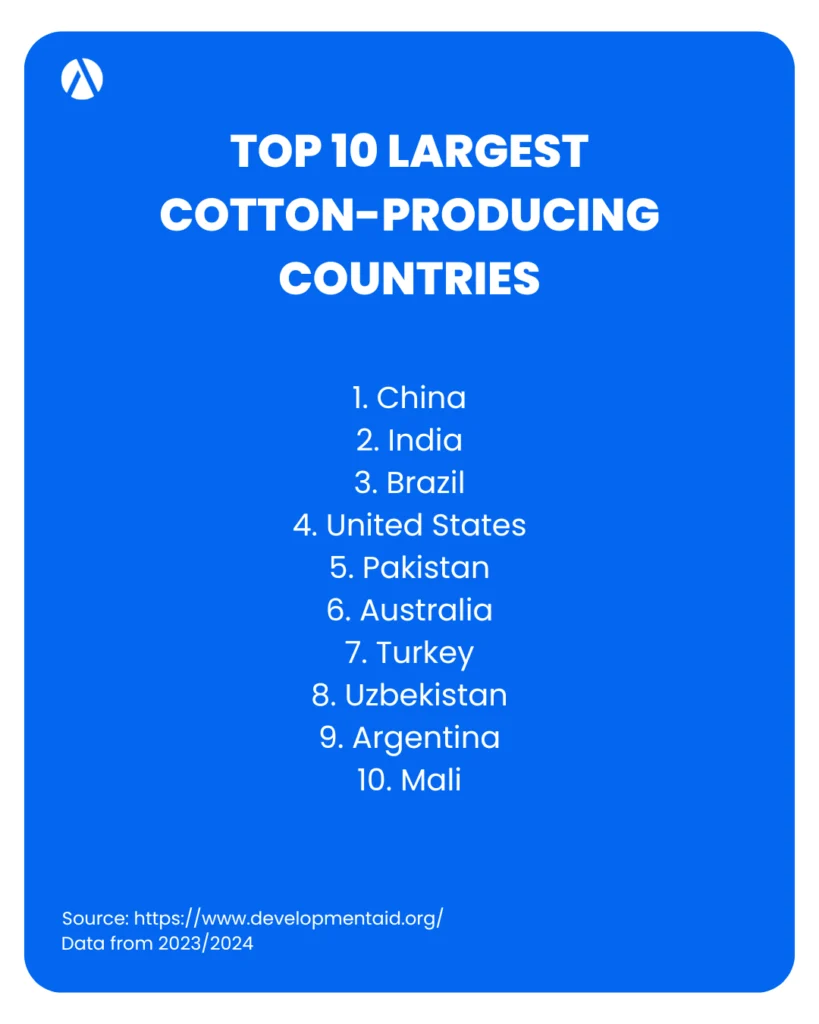

India is one of the largest producers of cotton in the world, which gives the country a massive competitive edge. This advantage supports both domestic manufacturing and international trade.

Cotton-based products are always in high demand worldwide. And India’s ability to meet this demand strengthens its role in the global market.

The industry is also a major source of employment generation, providing jobs to millions of people. It includes farmers growing cotton, artisans creating handmade fabrics, and workers operating advanced textile machinery.

Beyond economics, the textile industry influences culture and sustainability efforts. The country preserve and promote traditional crafts alongside modern manufacturing techniques.

A brief history of the textile industry in India

The history of Indian textiles goes back thousands of years. The Indus Valley Civilization were already famous for its fine cotton and silk. These fabrics stood out for their quality, vibrant colors, and intricate designs. Indians were already trading them across Asia, Europe, and the Middle East.

In medieval times, India became a major player in the global textile trade. Muslin, chintz, and calico gained international fame for their craftsmanship, strengthening India’s reputation as a textile hub.

The colonial era brought industrial production, often at the expense of traditional crafts. Yet after independence, India rebuilt its industry by combining ancient techniques with modern manufacturing.

Today, it remains a global force, blending heritage with innovation to stay competitive in world markets.

Learn more: Discover Indian fashion with stories, styles and designers

The textile industry in India in data

Main production hubs

The textile industry in India is spread across several key regions. Each hub plays a unique role, with different types of fabrics and techniques.

Gujarat, for example, is a leader in cotton production and textile manufacturing. It has cities like Ahmedabad, that is famous for large-scale mills. Tamil Nadu, especially Coimbatore and Tirupur, is a leader in knitwear and hosiery production.

In the north, Punjab and Haryana excel in producing blended fabrics. Meanwhile, Uttar Pradesh has a strong tradition in handloom weaving.

West Bengal is recognized for jute production, and Rajasthan for its colorful block-printed fabrics.

Learn more: How does the Asia Pacific market impact fashion?

Sustainability

Sustainability is becoming a growing priority in India’s textile industry, with many companies adopting eco-friendly practices. They include organic raw materials, natural dyes, and water recycling systems in factories.

These changes help reduce the environmental impact of large-scale production.

There is also a focus on preserving traditional techniques like handloom weaving. It consumes less energy and support rural livelihoods.

Learn more: What is a digital product passport in fashion?

Technology

Technology is reshaping the Indian textile industry at every stage. Automation and advanced machinery are helping factories increase efficiency, reduce errors, and improve quality control.

From smart supply chain management to AI-powered demand forecasting, technology allows Indian manufacturers to stay competitive.

This integration of innovation with traditional expertise is helping the country maintain its edge in the global textile industry.

Ready to take your company to the next level and maximize productivity? Get our free exclusive guide filled with expert tips to make it happen!

How is technology modernizing the textile industry in India?

Technology is transforming every stage of manufacturing, from creation to production and distribution.

With the textile industry in India couldn’t be different. Companies are embracing innovation to increase efficiency, reduce costs, and meet the evolving demands of global markets.

Check out the key technologies that are shaping this transformation:

Automation and robotics

Automation has become a game-changer for Indian textile companies. By replacing manual processes with advanced machines, factories can achieve faster production speeds without compromising quality.

Now, it’s possible to handle tasks like marking, spreading, and cutting with precision by automated systems.

Robotics further enhances efficiency and improve workplace safety. Modern machines can handle heavy materials, sharp tools, and hazardous processes. They reduce risks for workers while maintaining consistent output.

3D design and production software

The adoption of 3D design tools has deeply transformed textiles production in India.

Designers can now create detailed virtual prototypes before cutting any fabric. This approach reduces waste, saves time, and makes it easier to experiment with new styles and patterns.

At the same time, production software streamlines communication between design and manufacturing teams. Once a design is ready, brands can translate them directly into machine instructions, ensuring accuracy in the final product.

This integration allows brands to bring new products to market faster. In a competitive fashion industry, the ability to shorten development cycles can be a decisive advantage.

Learn more: Find out everything you need to know about 3D fashion design

On-demand manufacturing and Artificial Intelligence

On-demand manufacturing is gaining popularity as consumers seek more personalized products. In India, factories are adapting to produce smaller, customized batches instead of mass quantities.

Artificial Intelligence supports this model by predicting trends and consumer preferences. By analyzing large amounts of market data, AI helps manufacturers decide what to produce and when.

In addition, AI also streamlines the design process. With this technology, brands can create realistic simulations on a computer and generate print variations with a few clicks.

Technology for sustainability

Sustainability is slowly but surely becoming a focus of discussion in the textile industry in India. Manufacturers are using technology to monitor and reduce their environmental footprint, including recycling systems and energy-efficient machinery.

Digital tracking tools, like Fashion PLMs, make it possible to trace raw materials through the entire supply chain. This transparency helps brands prove their sustainability claims and comply with international standards.

Additionally, advanced dyeing and finishing technologies are reducing chemical use and water consumption. These innovations make eco-friendly practices more accessible to manufacturers of all sizes.

Learn more: What is a digital product passport in fashion?

Big Data and predictive analytics

Big Data is giving textile manufacturers valuable insights into their operations and markets.

By collecting and analyzing information from multiple sources, companies can identify trends, forecast demand, and optimize production schedules.

Predictive analytics goes one step further by anticipating future challenges. For example, it can suggest the best time to purchase raw materials. Or even detect potential supply chain disruptions before they happen.

These tools also help improve customer satisfaction. By better understanding buying habits and preferences, manufacturers can create collections that align closely with consumer needs.

Learn more: Explore the fashion future demands and anticipate what’s next in the market

Automate your textile industry in India with Audaces solutions

Learn how Audaces solutions assist with each stage of fashion production:

Audaces360

Audaces360 integrates cutting-edge digital innovations to optimize workflows in the textile and apparel industry.

It caters to companies of all sizes and types, offering the flexibility to scale with your business needs.

All solutions were carefully developed to address the specific challenges of the field. They streamline the design and production processes, saving valuable time and resources.

The platform boasts a comprehensive range of functionalities, including pattern making, marking, collection management, vector drawing, and 3D creation.

In addition, a fashion Artificial Intelligence to assist you along the way.

Audaces Cutting Room

By embracing cutting-edge technology, garment manufacturers can achieve significant improvements in the production process. From greater design flexibility to enhanced efficiency and reduced costs.

This is where Audaces Cutting Room steps in! Our experts will thoroughly assess your company’s needs and create a comprehensive report.

Then, our team will develop a personalized project to achieve your goals and unlock your company’s full potential.

Rely on Audaces’ cutting-edge machinery to automate your production process. Achieve impeccable cuts on curves and details, speeding up your deliveries and minimizing fabric waste through automation.

See how Aspen transformed its entire production with the automated Audaces Cutting Room:

FAQ

The textile industry is essential for India’s economy. It contributes significantly to the country’s GDP and holds a strong position in exports.

The history of Indian textiles goes back thousands of years. The Indus Valley Civilization were already famous for its fine cotton and silk.

Automation, robotics, 3D design, production software, on-demand manufacturing, Artificial Intelligence, and Big Data.