Summary

- In apparel manufacturing, the first step for handling fabrics involves spreading. That’s why it needs to be accurate from the very beginning.

- Key requirements that a reliable fabric spreader must meet include aligned layers, accurate tension, and the optimal height.

- Experience the future of the fashion industry with Audaces360. Start your free trial now!

Making clothes with quality, speed, and low waste is not an easy task. Every step in the process needs to work well, especially fabric spreading.

This stage may seem simple, but it plays a big role in your production costs and final results. A small mistake here can lead to fabric waste or delays. That’s why many companies are looking at technology to help.

If you’re thinking about upgrading your company or just want to know what a fabric spreader can do, you’re in the right place. In the next few paragraphs, you’ll find clear, simple reasons why this equipment can make a big difference.

Happy reading!

Sumário

What is the importance of an automatic fabric spreader for garment manufacturers?

Precision and speed are essential in garment production. That’s why more and more manufacturers are turning to automatic fabric spreaders to stay competitive.

This equipment ensures consistent fabric layers, improving cut quality and reducing waste. With better alignment and tension control, the chances of costly errors drop significantly.

Automation also speeds up the spreading stage, helping teams meet tight deadlines without sacrificing quality. It allows production lines to operate more smoothly and with fewer interruptions.

For manufacturers aiming to scale or optimize their processes, an automatic spreader isn’t just a convenience. It’s a strategic investment!

Automatic vs. manual fabric spreaders: understand the differences

Both manual and automatic fabric spreaders are used to prepare fabric for cutting. But they work in different ways and offer different results.

Let’s take a closer look at how each one works and what benefits they bring.

Manual fabric spreader

Manual spreading machines rely on human effort. Workers push or guide the machine along the table while it unrolls the fabric. Some versions include a simple frame or wheels to help move the material more smoothly.

This method works best for small productions or when the team has more time. It’s more affordable at first, and it requires less technology. But it can also be slower and less precise.

It takes more effort and often leads to small errors. If the fabric is not aligned well, it may affect the final pieces.

For some businesses, manual spreading might be enough. But for larger volumes or when speed is key, it may not be the best option.

Automatic fabric spreader

An automatic fabric spreader moves on its own along the table. It spreads the fabric quickly and evenly, with little effort from the operator. The machine can deliver tension free spreading and control alignment perfectly.

It makes the process faster and more reliable. It also improves the quality of the spread, which is important for accurate cutting. After all, less waste means more savings.

These spreaders also reduce physical strain on workers. Since the machine handles the heavy lifting and movement, the team can focus on other tasks.

This type of machine is ideal for medium to large factories. It brings more control, higher productivity, and better results with less effort.

Learn more: Discover what automatic fabric spreading is and how to make it properly

5 benefits of investing in an automatic fabric spreader

Choosing the right tools makes a big difference in garment production. An automatic fabric spreader can bring several advantages to your daily routine.

Below, you’ll find five key reasons why this equipment is a smart investment for your business.

1) More cost-efficient production

One of the biggest benefits of using an automatic fabric spreader is saving money. It helps reduce fabric waste by spreading layers evenly and precisely.

It also lowers labor costs. With automation, fewer people are necessary to handle the spreading process. That allows your team to focus on other tasks, making your operation more efficient overall.

Learn more: How does technology in fashion impact the textile industry?

2) Faster output

Speed matters in fashion production. And an automatic spreader works much faster than a manual one. It spreads fabric layers quickly and smoothly, keeping your workflow steady.

This speed helps you meet tight deadlines and manage larger volumes. You can prepare more fabric in less time, which is key for growing businesses or high-demand seasons.

Learn more: What is a smart factory and how to become one?

3) Fewer errors in the process

Manual spreading often leads to mistakes. Fabric can shift, stretch, or wrinkle, which affects the quality of the cut. Meanwhile, an automatic spreader avoids these problems with better control and consistency.

It also handles material rolls in a steady and even way. This reduces tension issues and helps maintain fabric quality from the first layer to the last.

If you want to ensure your company consistently delivers the best outcomes, look no further! Discover the technology that will transform your operations: Audaces Automated Cutting Room.

4) Versatility

Automatic spreaders work with different types of fabrics. Whether the fabric is thick, thin, slippery, or stretchy, the machine can adjust to your needs.

This flexibility is great for companies that work with a variety of collections or product lines. One machine can support many styles, helping you adapt to trends and customer demands.

Learn more: Smart uses of clean technology in clothing manufacturing

5) Increased profitability

Better use of fabric, fewer errors, and faster processes all lead to one thing: higher profits. With an automatic spreader, your resources go further, and your team works more efficiently.

By producing more in less time and reducing waste, your margins improve. This gives your business room to grow, without increasing costs at the same rate.

Learn more: How to boost production capacity in fashion manufacturing?

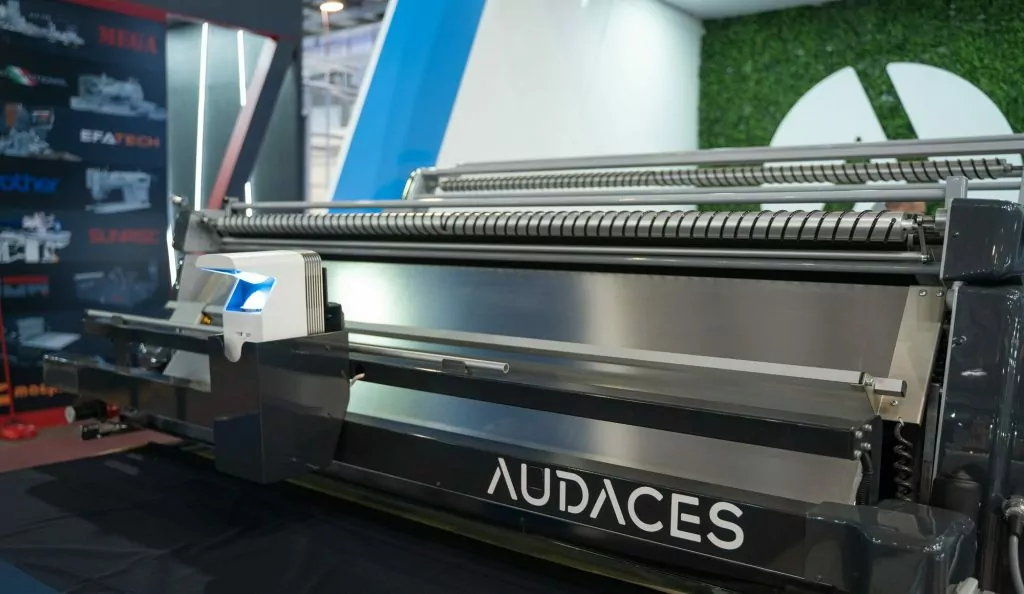

Discover Linea, the automatic fabric spreader from Audaces

Audaces Linea’s technology allows you to elevate your manufacturing operations to new levels of efficiency and quality.

This cutting-edge solution empowers you to schedule and execute multiple spreads within the same day. All with simple touches on the machine’s intuitive touchscreen interface.

Your business will benefit from a boost in autonomy and agility, in addition to improving product quality.

Learn more: Why should your company invest in fabrication technology?

What are the technical specifications of Audaces Linea?

- Useful work width: up to 180 cm and 220 cm

- Maximum roll diameter: 60 cm and 80 cm

- Maximum roll weight: versions available up to 100 kg and 200 kg

- Odd spread heigh: 22 cm

- Zigzag spread height: 12 cm

- Maximum speed: 100 m/min

See how Audaces Linea can fit into your business

If you have any doubts about fitting our equipment into your production line, there’s no need to worry. Our consultants are always available to advise you.

We offer a free, personalized consultation to identify your main needs and suggest the best-fitting equipment.

It’s time to take the next step in transforming your apparel manufacturing! Connect with one of our experts and see what Audaces can do for you.

FAQ

Precision and speed are essential in garment production. And this equipment ensures consistent fabric layers, improving cut quality and reducing waste. With better alignment and tension control, the chances of costly errors drop significantly.

Manual spreading machines rely on human effort. Workers must push the machine along the table. Meanwhile, an automatic fabric spreader moves on its own. It spreads the fabric quickly and evenly.

More cost-efficient production, faster output, fewer errors, versatility, and increased profitability.