Summary

- The textile industry is always evolving. And technology is a key driver in this transformation.

- To retain customers in today’s highly competitive market, it’s essential to improve quality.

- Experience the future of the fashion industry with Audaces360 solutions. Sign up for your free trial today!

From equipment to advanced software, technology helps improve how we make textile products. But how does this impact the quality of the items we use every day?

The answer lies in the details. Innovation not only speeds up production but also ensures precision. This has changed how designers and manufacturers think about quality.

In this text, we will explore how technology supports each step of the textile process. You’ll learn about tools and innovations that are shaping the industry.

Stay with us as we uncover these insights. Happy reading!

Sumário

Why is it important to sell high-quality textile products?

High-quality textile products build trust. Customers want textiles and fabrics that last, feel good, and look great. When they buy something that meets these standards, they are more likely to return.

Selling high-quality items also reduces problems. Poor-quality textiles can tear, fade, or shrink. This leads to complaints and returns, which cost time and money.

They also justify higher prices. Customers are often willing to pay more for something they know will last. This increases profits and allows your business to grow. It’s an investment that pays off over time.

Finally, quality reflects your brand. It shows that you care about the details and value your customers. A commitment to high standards sets you apart in a competitive market.

Learn more: What is the fashion industry, its value, and key players?

What are textile products?

Textile products are items made from fabrics. They are part of our daily lives and come in many forms. From what we wear to what we use at home, textiles are everywhere.

These products include a wide range of items:

- Clothes

- Technical fabrics

- Fashion accessories

- Home goods (like curtains and bed sheets)

- Medical fabrics

- Automotive textiles

- Performance fabrics (like sportswear)

Each type of textile product has a specific purpose. Clothes keep us comfortable and stylish. Technical and performance fabrics focus on durability and special functions, like protecting workers.

Home and automotive textiles improve the ambiance of living spaces and vehicles. Medical fabrics are important in healthcare, for items like bandages and hospital gowns.

How to ensure the quality of textile products?

Producing high-quality textile products requires attention to every detail. From materials to processes, each step plays an important role.

Choose high-quality raw materials

The foundation of a good textile product is the material. High-quality raw materials ensure durability and comfort. Fabrics with premium fibers are stronger and last longer.

Poor-quality materials can lead to issues like tearing or fading. Customers notice these flaws quickly. Investing in better raw materials saves time and money in the long run.

Look for suppliers who share your commitment to quality. Test materials before using them in production. A good start ensures better results.

Use cutting-edge machinery and software

Modern machinery ensures precision and efficiency. It helps create textiles with consistent quality. Advanced software also supports processes like design and production planning.

Old equipment can lead to errors and slow production. Upgrading technology solves these issues. It also reduces waste and saves costs.

Audaces has harnessed its industry expertise to deliver cutting-edge solutions that address your challenges.

Our automated cutting room, equipped with advanced machinery, optimizes your manufacturing processes.

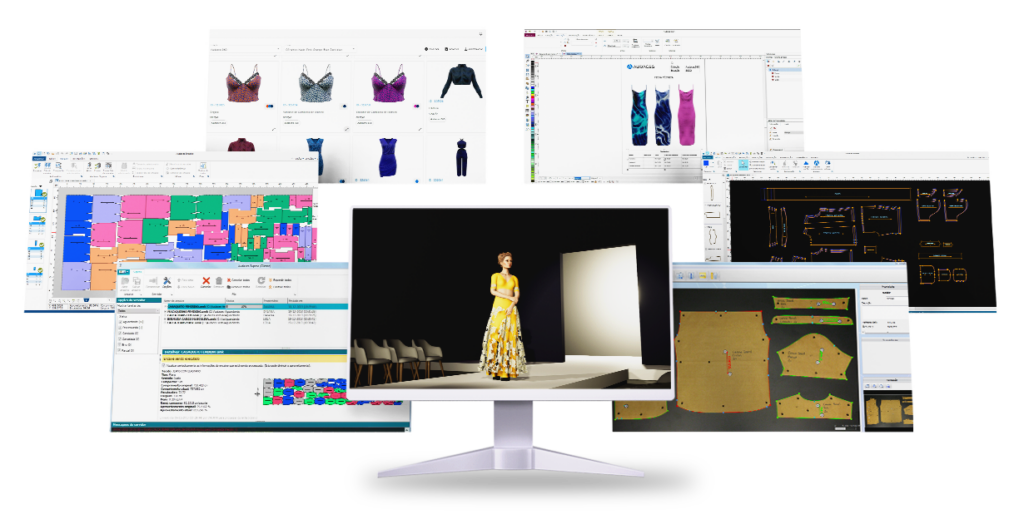

Meanwhile, with Audaces360 you’ll experience a streamlined and integrated approach to design and production.

Automation and smart solutions enhance accuracy. They help meet the demands of today’s competitive market. Investing in technology is investing in your success.

Learn more: Why should your company invest in fabrication technology?

Train your team for the technologies

A skilled team is key to using new technologies effectively. Proper training helps employees understand advanced tools and techniques.

Without training, mistakes can happen. This affects quality and production speed. A well-trained team works with confidence and accuracy.

Organize regular workshops and courses. Keep your team informed about updates in machinery and software. When employees feel empowered, the results are better.

Discover how to seamlessly integrate technology into your business without disrupting production. Download our comprehensive guide for free today.

Monitor all stages of production

Quality control is essential from start to finish. Monitor each step, from raw materials to final packaging.

Check for flaws during production, not just at the end. This saves time and prevents costly rework. Small mistakes can grow into bigger problems if overlooked.

Use tools like inspections and automated sensors to catch errors early. Keep detailed records to identify patterns and improve processes.

Continuous monitoring ensures consistent quality. Attention to detail at every stage makes a big difference.

Make constant updates

The textile industry evolves quickly. Staying competitive means making regular updates to your processes and products.

Customer expectations change, and so does technology. Update your designs, materials, and machinery to meet these demands. Staying stagnant can lead to falling behind.

Preventive maintenance is also important to ensuring your machinery operates smoothly. Regular checks and upkeep reduce the risk of breakdowns and production delays. This helps maintain consistent quality over time.

Learn more: 6 essential steps for choosing the perfect CAM technology

How does technology improve the quality of textile products?

Let’s explore key areas where technology can make a difference in your textile company:

Digital sketches

Digital sketches make the design process faster and more accurate. Designers can create and edit ideas easily using software.

With digital tools, you can test colors and patterns quickly. Make changes in real time without wasting materials. This ensures designs are polished before production begins.

Collaboration is easier with digital sketches. Teams can share and review ideas instantly. It speeds up decision-making and improves results.

Digital sketches set a strong foundation for high-quality textile products. They bring creativity and efficiency together.

Learn more: How can easy clothing help you speed up fashion creation?

Pattern digitalization or creation

Advanced solutions allow for creating and storing patterns more efficiently. Pattern makers can adjust patterns easily without starting from scratch.

They reduce the risk of errors. By digitally testing fit and alignment, you can eliminate production confusion.

You can also store and reuse them for future collections. This streamlines the design process and maintains consistency. Using digital patterns also allows for easy and precise grading.

Automatic size grading

Technology simplifies size grading. Automatic Solutions adjust patterns for multiple sizes with accuracy.

They ensure consistency across all sizes. It helps eliminate human error, producing garments that fit better. Customers notice and appreciate this precision.

These tools also allow for quick adjustments. If a size needs tweaking, you can do it instantly. This speeds up the development and production processes.

Virtual prototyping

Virtual prototyping lets designers see how a garment looks before making it. 3D models show the fit, drape, and movement of fabrics.

They eliminate the need for physical samples early in the process. You can also make tweaks directly on the digital prototype.

Designers can test different colors, fabrics, and sizes instantly. This reduces costs and waste.

With virtual prototyping, you can test quality before production even starts. It’s an efficient way to innovate textile products!

Learn more: Why simulate the 3D fit of garments before production?

Efficient marking and cutting

Automated marking software and cutting equipment improve precision. They ensure patterns are cut accurately, reducing errors.

These machines also speed up the process. Companies can cut large volumes of fabric quickly, meeting tight deadlines. This is especially useful for bulk orders.

In addition, efficient cutting minimizes fabric waste. It reduces costs and supports sustainability efforts. High-quality solutions improve both the environment and your bottom line.

Learn more: The ultimate guide to create a marker for fabric cutting

Collection management

Technology helps organize and track collections easily. Teams can manage and approve designs efficiently.

These systems store data for future use. Designers can revisit past collections to refine or reuse ideas.

Digital management tools also foster collaboration between teams. Designers, manufacturers, and marketing teams can work together, sharing updates in real time.

This improves coordination and ensures everyone is on the same page.

Automate your textile production with Audaces

Audaces360

Audaces360 integrates cutting-edge technology to optimize workflows in the textile and apparel industry.

We’ve carefully developed all solutions to address the specific challenges of fashion businesses. They streamline your design and production processes, saving valuable time and resources.

It boasts a comprehensive range of functionalities. They include pattern making, marking, collection management, vector drawing, and 3D creation.

In addition, a fashion Artificial Intelligence to assist you along the way.

Audaces Cutting Room

Audaces Cutting Room combines software and hardware solutions for the textile industry.

Our experts will thoroughly assess your needs and create a comprehensive report. Then, a specialized team will develop a personalized project to unlock your company’s full potential.

Rely on Audaces’ cutting-edge machinery to obtain great improvements in production. From greater design flexibility to enhanced efficiency and reduced costs.

Achieve impeccable cuts on curves and details, speeding up your deliveries and minimizing fabric waste through automation.

Want to stay up to date on the latest fashion industry news? Subscribe to our newsletter!

FAQ

High-quality textile products build trust. Customers want textiles and fabrics that last, feel good, and look great. When they buy something that meets these standards, they are more likely to return.

Textile products are items made from fabrics. They are part of our daily lives and come in many forms. From what we wear to what we use at home, textiles are everywhere.

Choose high-quality raw materials, use cutting-edge machinery and software, train your team for the technologies, monitor all stages of production, make constant updates.