Summary

- Marker-making is essential to ensure the best use of raw materials in apparel companies.

- It delivers high-quality products and enhances the efficiency of processes in manufacturing.

- Learn how technology can help you. Try Audaces360 multi-solution for free now!

The marker stage is one of the most crucial aspects of production efficiency in apparel manufacturing. It influences quality production and impacts the sales potential of collections.

Optimizing the marker creation can mean the difference between profitable operations and tight margins. That’s when advanced technology steps in — to maximize results.

Cutting-edge software with intelligent algorithms has transformed this process. Automatic marker allows precision and significant savings in time and resources.

Discover the best options for your business in our guide now. Enjoy your reading!

Sumário

Why does creating automatic marker on the computer help the patternmaker?

In the apparel industry, a marker is a precise plan for cutting fabric. It arranges all the pattern pieces efficiently on the spread fabric. This minimizes material waste while maintaining the grain direction of the textile.

There are multiple other benefits associated with automatic marker. Here are the main ones:

1) Time optimization

Automatic marker streamlines several repetitive steps, such as rotating and positioning patterns. It frees up time for patternmakers to focus on more creative and strategic tasks.

The impact on production efficiency is huge! Automatic marker leads to faster cutting times, whether done manually or by machine.

Additionally, the software allows for quick testing of different marker setups. This lets patternmakers calculate the fabric consumption and marker’s layout before committing to a final version.

2) Error reduction

The automation of the process guarantees precise and consistent measurements, excluding manual errors and ensuring a perfect fit.

Automatic marker reduces the chance of human error, decreasing the need to redo work or correct mistakes.

Moreover, it allows to standard the fitting process, ensuring quality and consistency throughout the entire production process.

Learn more: 10 pattern making and marking challenges and how to solve them

3) Sustainable process

Optimized automatic marker minimizes fabric waste, reducing production costs and environmental impact.

Software developed for this purpose allows for making the most of the available material, enhancing consumption and reducing waste.

A sustainable process becomes a pillar of automatic marker, contributing to more responsible and environmentally friendly practices.

Learn more: Why consider sustainable consumption and production for your company?

4) Enhanced communication

Automatic marker presents the pattern pieces on the fabric layout in a clear and intuitive way. It improves communication between patternmakers and other professionals involved in production.

Computerized marker layout files are easy to share with the team, preventing delays and reworks.

Clear and standardized communication fosters teamwork and ensures that everyone is on the same page.

Learn more: 4 textile technologies that are reshaping fashion

Manual vs. Automatic marker in the daily life of a patternmaker

Compare the two methods and discover which one makes more sense for your work routine:

Manual marker

Manual marker involves physically arranging and adjusting paper pattern pieces on the fabric.

Pros

- Lower initial investment: requires minimal equipment compared to digital software.

- Relatively easy to learn: suitable for beginners or those new to patternmaking.

Cons

- Prone to errors: manual adjustments can lead to problems with size and fit.

- Time-consuming: creating marker by hand can be slow and laborious.

- Material waste: trial-and-error adjustments can lead to wasted fabric.

- Limited communication: sharing physical patterns with more people can be difficult.

- Difficult to scale: manually creating marker is not efficient for mass production.

- Archiving: physical patterns can take up storage space and damage over time.

Automatic marker

On the other hand, automatic marker utilizes computer software to create, manipulate, and optimize pattern pieces within a virtual environment.

Pros

- High accuracy: ensures precise measurements and consistent fit through digital tools.

- Increased efficiency: streamlines the entire marker and cut processes.

- Reduced material waste: optimizes fabric usage through automatic marker making.

- Improved communication: digital files are easy to share among teams.

- Easy to scale: adaptable for large production runs with digital files.

- Archiving: digital files are simple to store, with no risk of degradation.

Cons

- Initial investment: requires an upfront cost associated with purchasing automatic marker software.

- Training: it is necessary to invest time and effort in training to fully utilize the software’s capabilities.

Learn more: Understand the importance of a pattern maker for fashion manufacturing

How to create automatic markers on your computer?

Automatic marker is a valuable solution for patternmakers and garment manufacturers. It helps optimize fabric usage, minimize waste, and streamline the production process.

Here is the step-by-step guide to creating the perfect automatic marker:

Choose reliable software

Select reputable automatic marker software that aligns with your needs and budget. Consider factors like ease of use, features, and how it can integrate with your workflow.

To make an informed decision, seek recommendations from other businesses in your industry and conduct online research. Watch review videos to observe how people use the software and assess if it is intuitive.

Ideally, opt for companies that offer trial versions. This allows the patternmaker to test the solution and evaluate if it is the best fit to assist their work.

Learn more: Learn how to choose the best fashion CAD for your business

Design your digital pattern

To ensure maximum production efficiency, choose software that offers integrated solutions. These suites offer a comprehensive set of tools for all stages of the development and production process.

They enable you to digitize existing paper patterns, converting physical patterns into digital files. They also encompass the development of digital patterns, the core function you need for automatic marker creation.

Design new patterns directly within the software to leverage its capabilities for precision and efficiency.

By adopting an integrated solution, you can streamline your workflow and achieve a seamless transition to automatic marker.

Adjust and grade patterns

Digital software streamlines the process of creating patterns for different sizes. You can define a base size and apply grading rules.

This automatically generates patterns for a range of sizes while ensuring a consistent fit and optimal fabric usage.

Digital patterns are also very adaptable. They are easy to modify and adjust, allowing for quick exploration of design variations.

For example, the software makes it easy to try out different lengths and add new details to bring your creative vision to life.

Learn more: How to apply PPC for manufacturing in your fashion business?

Incorporate essential details

The ability to incorporate essential details like seam allowances, notches, and buttonholes into digital patterns unlocks significant advantages.

Firstly, it simplifies the prototyping stage. You can add details easily in the software to create garment samples faster. This helps you try out different design options more quickly.

It eliminates the time-consuming process of manually adding details to physical patterns, streamlining the entire design development cycle.

Review, adjust, and save your pattern

Thoroughly review the pattern pieces for accuracy and consistency. Make any necessary adjustments to ensure the patterns are ready for creating automatic marker.

One of the essential benefits of digital patterns is that you can zoom in and out to inspect their quality in detail.

If you detect any error, it is possible to make precise adjustments to any part of the pattern. Unlike manual methods, there’s no need to re-draw or cut the entire pattern piece.

In addition, software solutions securely save patterns and markers as digital files. It ends the need for physical storage space, and you can use them as many times as you want.

Learn more: 5 strategies to optimize your production with efficient fashion

Optimize your marker making with Audaces

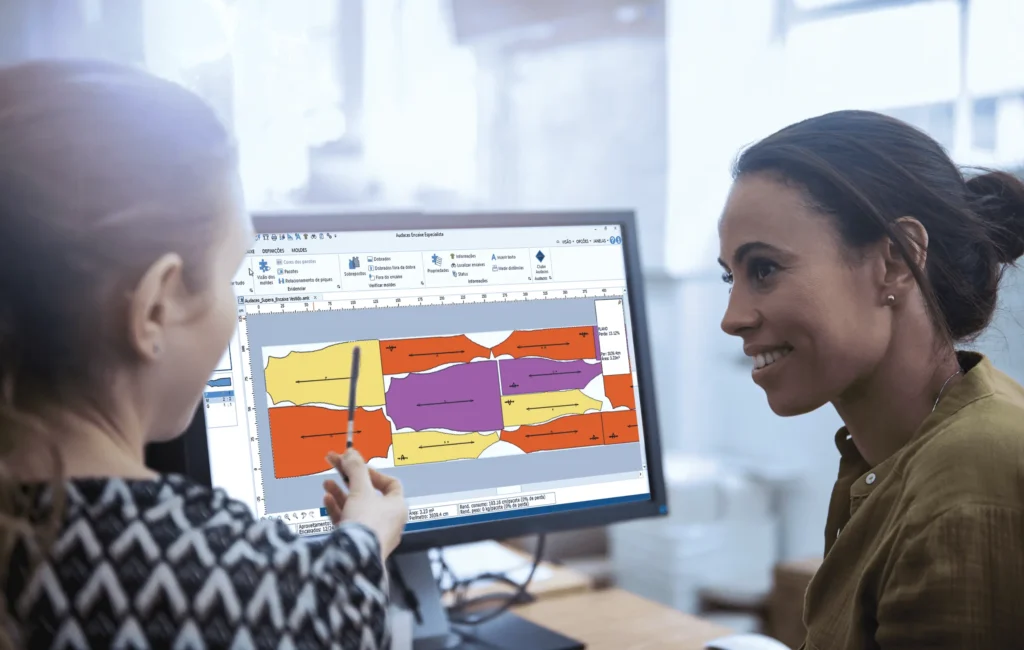

Audaces Marker

Raw materials play a crucial role in the production cost of any garment. Optimizing this resource is essential for achieving large-scale profits.

No matter the size of your apparel manufacturing – small, medium, or large – optimizing fabric usage is key. This is where Audaces Marker steps in to help!

Audaces Marker is an innovative solution that enables maximum fabric usage during the cutting process.

Every centimeter saved can translate into meters of fabric over time, resulting in a significant increase in profits. With this technology, manufacturers can reduce waste in every layer of fabric. It not only lowers costs but also contributes to a more sustainable production process.

This solution allows companies to achieve perfect automatic marker, ensuring the use of every piece of fabric. This directly impacts revenue generation through collection sales. You can produce more with the same amount of raw material.

Maximize profits and reduce waste! Improved efficiency allows businesses to create more products to meet customer demand and expand their operations.

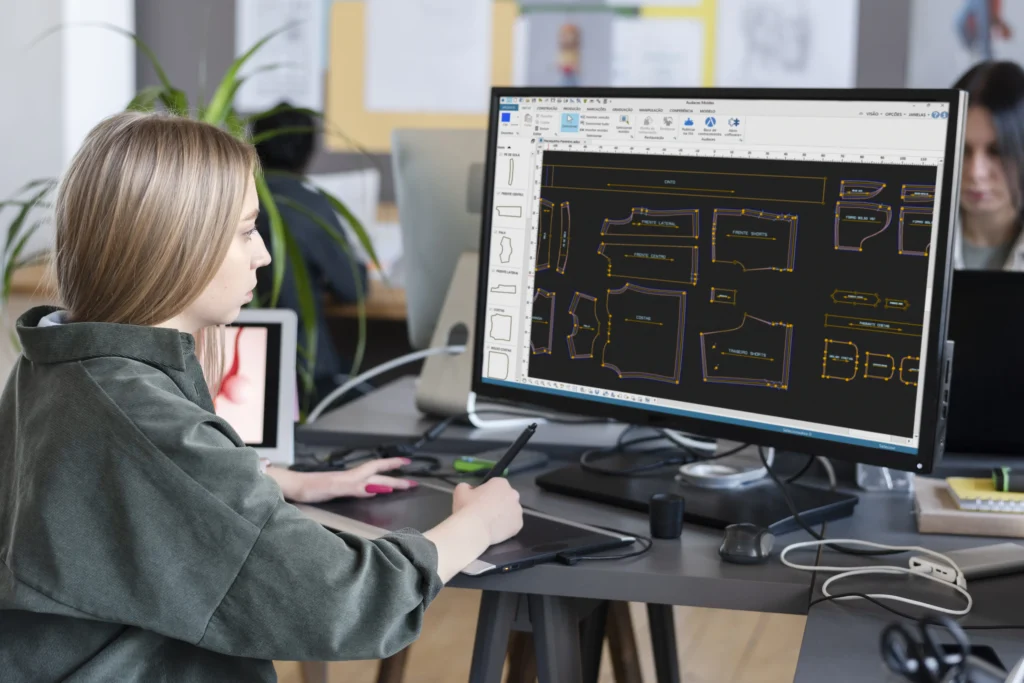

Audaces Supera Max

Audaces Supera Max is an advanced marker server powered by Artificial Intelligence. We developed it maximize fabric usage and reduce production times.

It offers a range of benefits that transform the way apparel companies operate. It minimizes fabric waste and streamlines the production process, ensuring significant savings in time and raw materials.

With the capability of efficient queue management, you can plan marker queues sent from one or more computers.

Audaces Supera Max allows for free workstations, so you can prepare the next automatic marker. Moreover, you can define the order in which markings should be calculated first.

Unlock the full potential of your apparel manufacturing with our e-book. Download it for free now!

FAQ

It arranges all the pattern pieces efficiently on the spread fabric. This minimizes material waste while maintaining the grain direction of the textile.

Manual marker involves physically arranging and adjusting paper pattern pieces on the fabric. On the other hand, automatic marker utilizes computer software to create, manipulate, and optimize pattern pieces within a virtual environment.

Choose reliable software, design your digital pattern, adjust and grade patterns, incorporate essential details, and review, adjust, and save your pattern.