Summary

- A technical sheet acts like a roadmap, ensuring each step of production aligns with your vision.

- Creating a clear and complete furniture spec sheet is key to avoiding costly mistakes.

- Leverage technology to create precise and efficient spec sheets. Try Audaces360 for free today!

A good spec sheet gives essential details about each piece, guiding designers and manufacturers through the process with accuracy.

With the right information on the sheet, everyone involved understands the materials, dimensions, and finishes. It sets expectations and provides a reliable reference point for production.

This guide will introduce you to what’s most important in a spec sheet to keep your furniture production smooth. Explore how to set up a document that keeps your project on track.

Happy reading!

Sumário

Why rely on a complete furniture spec sheet?

A complete furniture spec sheet is key for getting the design just right. It has all the important details, ensuring that everyone knows exactly what to do.

When you rely on a detailed spec sheet, you reduce the chances of mistakes. It leaves less room for guessing and keeps each step of production on track.

Your vision is clear from the start. This can save time, money, and prevent reworks.

A spec sheet also helps keep communication smooth between teams. Having a single document to guide production can make the entire process more efficient and stress-free.

Learn more: Uncover 5 expert tips on how to create a tech pack successfully

What is a furniture spec sheet?

A furniture spec sheet is a document that describes a piece of furniture in detail. It includes dimensions, materials, finishes, and assembly instructions.

This sheet acts as a blueprint, giving clear guidance on how to create or assemble the furniture.

Designers use them to outline the look and function of a piece. Manufacturers use them to know exactly what to build. Clients may even use them to understand what to expect.

The purpose of a spec sheet is to avoid confusion and mistakes. By listing each important detail, everyone has a reference point. It makes sure the final product matches the original design.

In short, a furniture spec sheet keeps the process organized and consistent. It’s a simple but powerful tool for quality and clarity in furniture production.

Learn more: Discover how to choose the perfect furniture design software

What information should be in a furniture spec sheet?

If you’re an interior designer, you should know a complete spec sheet covers all details of a furniture piece. Here’s what to include to avoid mistakes:

General description of the furniture piece

Start with a brief description of the furniture item. This can include its style, intended use, and any special features.

A simple description helps set the context and lets others understand the furniture’s purpose.

For example, is it a modern chair, a traditional sofa, or a minimalist table? Describe its main characteristics to make the vision clear.

Providing an overview helps everyone involved get a quick sense of the design and its function.

The general description also outlines where the piece fits, like in a living room or office. It keeps the team on the same page regarding the overall look and feel.

Precise dimensions

These measurements guide the production team, helping them make the piece as designed. Even small dimension errors can affect the final look and function, so accuracy is essential.

You can use these primary measurements as a reference:

- Height: measure from the base to the top of the furniture.

- Width: measure from one side to the other, across the furniture’s lateral dimension.

- Depth: measure from the front to the back of the piece.

- Seat height (for chairs): measure from the floor to the top of the seat.

- Shelf thickness or other components: include thickness measurements for shelves or specific parts.

Double-check each measurement to avoid costly mistakes. Precise dimensions make sure the furniture fits as planned, both in the room and with other pieces.

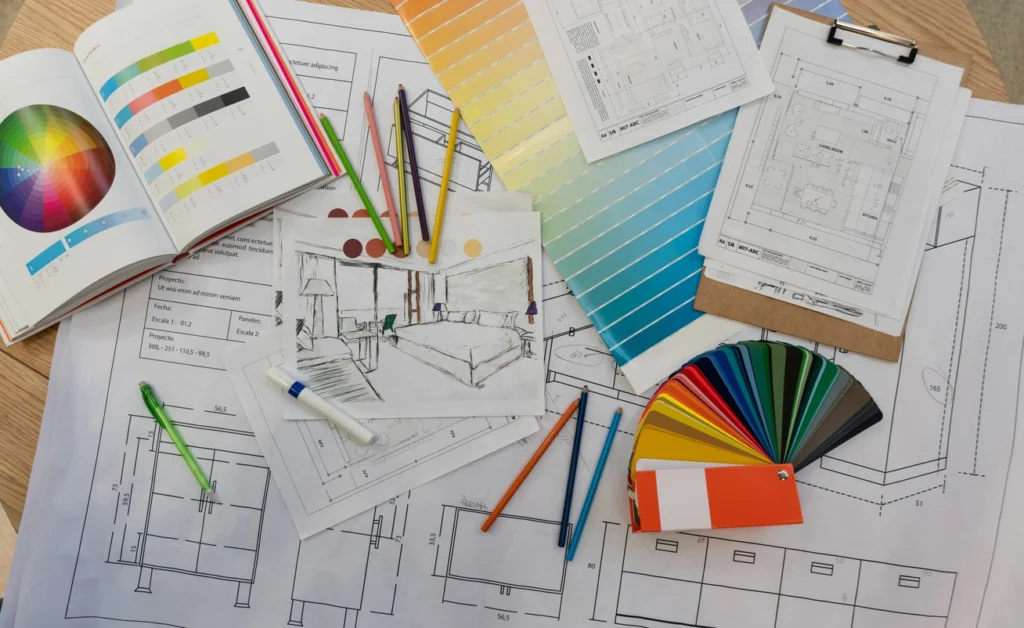

Flat sketch

A flat sketch shows the design from a simple, straightforward angle. This can be a line drawing that shows the furniture’s basic shape.

The sketch helps everyone visualize the layout and proportions without complex details. It’s a helpful tool for both the designer and the manufacturer.

It serves as a reference for placement of parts, like arms, legs, and other elements. Even a simple visual gives clarity, reducing the chance for errors.

A clear, accurate sketch makes it easy to see the whole piece at a glance. It provides a quick way to check the main structure and layout before moving forward.

Start creating spec sheets right now! Download our quick guide and get two free worksheet templates.

Materials employed

List all the necessary materials to make the furniture. This includes wood types, metals, plastics, or other primary elements. Identifying each material keeps the quality and look consistent.

Materials affect the furniture’s durability and appearance. By specifying materials, you ensure the piece will look and perform as designed.

This way, the manufacturer knows exactly what to use, avoiding any substitutions or guesswork.

The list of materials helps the client understand the quality of the piece. It also allows for better planning in terms of cost and sourcing.

Learn more: Step-by-step on how to apply pattern pictures in your design

Fabrics and other materials

If the piece includes fabrics or upholstery, describe them in detail. Mention the type of fabric, color, and pattern. This section should also include any additional materials like foam, padding, or linings.

Fabrics have specific textures, weights, and colors that impact the result. By noting these details, you help maintain consistency. Specify any treatments like stain resistance to clarify expectations.

Listing these materials ensures the furniture matches the design, both in appearance and comfort. The manufacturer will know exactly what to apply, leading to a satisfying finished product.

Learn more: Learn how to use types of nautical fabric in your upholstery production

Details and notes

This section includes any special notes about the piece. It might cover assembly instructions, finishing touches, or special handling requirements.

Details may include information on hardware, like bolts or screws, needed for assembly. It can also mention any custom features that require special care.

Clear notes prevent confusion and help the production team execute the design correctly.

Adding these specific notes ensures that each part of the furniture meets the expected standard. It’s the final step in creating a well-rounded spec sheet that everyone can rely on.

How to ensure clear specifications in a furniture spec sheet?

A clear furniture spec sheet keeps everyone on the same page. Here are some tips to make your specs clear and easy to follow.

Create from a standard template

Start with a standard template to organize all important details. Templates help you remember each necessary part. They keep the information in a familiar order, making it easier to fill out accurately.

Templates also help ensure consistency across projects. When everyone uses the same layout, it’s easier for teams to understand and find details quickly.

It saves time and reduces the chance of missing key information.

Choose or create a template that works well for your type of furniture. A reliable template is a solid base for a clear and organized spec sheet.

Be specific and precise when filling it out

Clear specs require specific details. Use precise measurements, exact material names, and clear notes. This leaves no room for guessing and keeps production on track.

Avoid vague terms like “large” or “standard.” Instead, give exact dimensions and materials to reduce mistakes. Precise wording makes it easier for each team to do their part.

Being specific also helps communicate with clients. They’ll know exactly what to expect, making the process smoother from start to finish.

Learn more: 4 advantages of technology in automotive furniture design

Use a good software solution

A good software solution makes furniture spec sheets easy to create and update. It helps you store and organize specs digitally, which is useful for quick access and editing.

Some software even offers templates or automatic formatting tools. They also make it easier to share spec sheets with your team.

Everyone can view and update the information in real time. This keeps all team members on the same page.

Look for software that matches your workflow. The right program can make the process faster, clearer, and more efficient.

Review all information

After completing the furniture spec sheet, review it carefully.

Double-check each detail, like measurements and materials, to make sure everything is accurate. This extra step helps prevent errors before production starts.

Ask another team member to review it too. A fresh pair of eyes can catch mistakes you might have missed. This team review adds another layer of accuracy.

Taking time to review ensures that each spec is correct. It gives you confidence that the final product will meet your standards and the client’s expectations.

Learn more: What is the best 2D design software to invest in?

Create your next furniture spec sheets with Audaces Idea

Audaces Idea is a powerful solution for creating precise and organized furniture spec sheets. It makes the entire process faster and easier, allowing you to create clear and accurate documents.

With Audaces Idea, you can organize all key details, from measurements to materials, in one place.

The software includes templates that guide you through each part of the spec sheet, making sure nothing important is left out.

It keeps your team on track and helps communicate your design clearly.

Discover Audaces360 and unlock a world of possibilities for textile design and production. Explore our comprehensive suite of solutions today!

FAQ

A complete furniture spec sheet is key for getting the design just right. It has all the important details, ensuring that everyone knows exactly what to do.

A furniture spec sheet is a document that describes a piece of furniture in detail. It includes dimensions, materials, finishes, and assembly instructions.

General description of the furniture piece, precise dimensions, flat sketch, materials employed, fabrics and other materials, and details and notes.