Summary

- The automotive market is a cornerstone of global economies and is always innovating.

- Staying competitive as a component supplier in the industry requires investing in technology.

- Our solution offers a complete package to automate your automotive furniture production. Try Audaces360 for free today!

The automotive industry is a complex ecosystem that includes manufacturers, suppliers, and dealers. Today, one of the main production methods relies on Original Equipment Manufacturers (OEMs).

OEMs produce parts for the assembly of finished products by another manufacturer. If your company produces automotive furniture, it fits into this category.

To enhance production and gain a competitive advantage, you must invest in the right technology. That’s why we’ll explore the latest innovations and guide you in selecting the best solutions.

Happy reading!

Sumário

Is automation in automotive furniture production worth it?

Automating automotive furniture production is essential for achieving superior quality and efficiency. Specialized technology ensures precision and reduces waste while increasing output.

Over time, the investment in software and equipment pays for itself, resulting in a rapid return on investment.

You’ll see a big difference in your company’s efficiency. It will deliver more products in the same timeframe. This is especially important in the rapidly evolving automotive industry.

Advancements like electric and autonomous vehicles are no longer futuristic concepts. They are a reality. Thus, staying ahead is crucial for market success.

Automation ensures consistent production, guaranteeing that every part meets strict quality standards. With the high cost and consumer expectations for cars, this consistency is paramount.

Many companies are pursuing design innovations that demand intricate details. Achieving this level of precision requires specialized machinery and software.

Consequently, investing in automation prepares you to win over even the most demanding clients.

Learn more: Why should your company invest in fabrication technology?

Main types of automotive furniture made with fabric

Automotive furniture, or interior components, define a vehicle’s aesthetic and comfort. Fabric is a versatile material and a key component in automotive furniture components.

These are the main parts you can explore in your production:

Seats

Seats are the most prominent fabric-based component in a vehicle. They are the first thing people typically notice in a vehicle’s interior. Therefore, they require careful design for ergonomics, comfort, and durability.

Technology can optimize seat design through 3D simulation software. They provide a realistic preview of the final product.

Additionally, automated cutting machines can enhance precision and efficiency in seat production.

Learn more: What is the best 3D design software to invest in?

Door panels

Door panels serve both functional and aesthetic purposes. Manufacturers typically cover them in fabric or leather.

Modern technology aids in reproducing intricate designs through pattern making. It contributes to a more refined and upscale vehicle interior.

Moreover, advanced cutting systems and automated assembly lines can streamline the production process.

Learn more: How to obtain quality and precision in the cutting fabric process?

Storage compartments

From glove boxes to center consoles, storage compartments are essential for vehicle organization. They can also add a touch of luxury. Customizing the design to match the interior theme enhances this effect.

Tech solutions can help to optimize compartment design for maximum storage capacity. This can become a deciding factor when the final consumer is making their purchasing decision.

Armrests

Armrests provide comfort and support for drivers and passengers. Fabric-covered armrests can enhance the vehicle’s interior appeal.

Businesses can employ digital tools to analyze armrest ergonomics. This allows for the optimization of shape and padding.

Sunroofs and headliners

While primarily structural components, sunroofs and headliners often incorporate fabric elements.

Headliners, in particular, impact the vehicle’s interior ambiance. Technology assists in designing headliners that optimize acoustics and insulation.

Moreover, an automated cutting process can improve production efficiency and quality.

Learn more: How to define production stages using a textile flowchart

Carpets

Carpets add warmth, comfort, and sound insulation to a vehicle’s interior. Modern carpet manufacturing involves advanced textile technologies. They create durable, stain-resistant, and aesthetically pleasing carpets.

Digital solutions guarantee accurate patterns to fit every part of the vehicle interior. Meanwhile, perfect marking reduces fabric waste.

Tired of the hassle of pattern making and marking? Download our free guide now and streamline your production!

Cargo covers

Cargo covers protect the cargo area and enhance the car’s appearance. Fabric cargo covers offer a balance of convenience and style.

Technology has the power to optimize cargo cover design for easy storage and deployment. Even these small details contribute to increasing the value of the final product.

Head restraints

Head restraints are paramount for both safety and comfort. Like other automotive furniture components, they also contribute to the vehicle’s aesthetics.

Because they involve curved shapes, headrests can become a challenge. Their patterns typically have complex details, so software with specialized tools ensures flawless work.

Software and hardware must work connected to achieve consistent quality while reducing production time.

Advantages of creating automotive furniture using technology

Technology has transformed the industry, and its impact on automotive furniture production is clear.

By adopting advanced tools and software, manufacturers can achieve improvements in efficiency, quality, and level of personalization.

1) Greater precision in pattern making and cutting

Accurate pattern making is key to creating precise and visually appealing automotive furniture parts. Software solutions like CAD help professionals craft detailed patterns with high precision.

Advanced cutting machines then follow these patterns exactly, cutting down on mistakes and saving materials. It not only enhances quality but also speeds up production and lowers costs.

To achieve this, seamless integration between software and hardware is essential. When automating your business, choose manufacturers that offer a comprehensive solution. This guarantees optimal outcomes and a smooth implementation process.

Learn more: Learn how to choose the best fashion CAD for your business

2) Reduced material waste

Material waste is a significant concern in the automotive industry. Through the use of technology, even Original Equipment Manufacturers can optimize material usage.

Precise pattern making ensures that fabric matches the exact dimensions required, minimizing excess scraps. By using an integrated marking solution, you can use raw materials as efficiently as possible.

Additionally, advanced cutting machines can handle complex shapes efficiently, further reducing waste.

Learn more: How to set up a plotter room for your clothing manufacturing

3) Enhanced quality control

Technology plays a vital role in maintaining consistent product quality. Automated inspection systems can detect defects in the production process, ensuring high-quality components.

This is particularly beneficial for high-volume production, since these solutions can accommodate both small and large orders. This flexibility is essential for effortlessly fulfilling varying requirements.

Furthermore, data analysis tools can identify areas for improvement, leading to continuous quality enhancement.

4) Customer personalization

As consumer demand for personalized products grows, you as a supplier need to follow suit, just like car manufacturers.

This offers a chance to reach a wider customer base, especially those seeking unique products.

To capitalize on this trend, leverage technology to provide a broader range of options. Digital design solutions allow your clients to visualize different fabric patterns, colors, and textures.

Moreover, automated production systems can accommodate individual preferences, allowing for mass personalization without compromising efficiency.

Choose Audaces solutions for your next automotive furniture production

Audaces Pattern

If your company is looking for excellence, Audaces Pattern is the perfect solution. It ensures the pattern development process reaches a new level of efficiency and precision.

With its dynamic and versatile approach, it is possible to develop high-quality patterns, regardless of complexity. It includes automotive furniture with intricate elements.

Refine every detail to perfection, ensuring that your projects translate into patterns. This advanced solution will assist you with all your patternmaking endeavors!

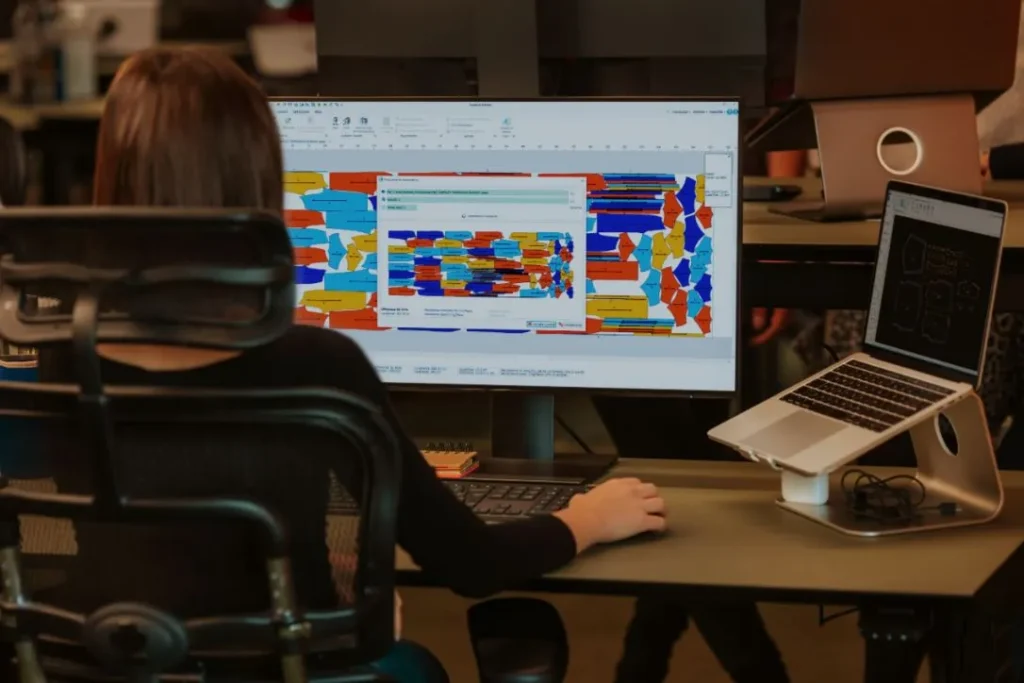

Audaces Marker

If you’re in the automotive furniture business, you know that raw materials are important in determining your costs. Optimizing this resource is essential for achieving large-scale profits.

No matter the size of your apparel manufacturing – small, medium, or large – optimizing fabric usage is key. This is where Audaces Marker steps in to help!

This is our innovative solution to maximize fabric usage by creating perfect and cost-effective markings.

Every centimeter saved can translate into meters of fabric over time, resulting in a significant increase in profits. With this technology, manufacturers can reduce waste in every layer of fabric.

It not only lowers costs but also contributes to a more sustainable production process!

Audaces Cutting Room

Looking for complete automation? Audaces Cutting Room offers the perfect solution.

Seamlessly integrate software and machinery to maximize precision and efficiency in your automotive furniture production.

Our experts will thoroughly assess your company’s needs and create a customized automation project. This way you can achieve impeccable cuts on curves and details with our smart cutting machine.

This not only speeds up deliveries but also boosts your results by delivering superior products to your customers.

Partner with a company boasting over 30 years of textile industry expertise, ensuring an exceptional return on investment!

Click here to request your personalized project.

FAQ

Automating automotive furniture production is essential for achieving superior quality and efficiency. Specialized technology ensures precision and reduces waste while increasing output.

Seats, door panels, storage compartments, armrests sunroofs and headliners, carpets, cargo covers, and head restraints.

Greater precision in pattern making and cutting, reduced material waste, enhanced quality control, and customer personalization.