Summary:

- Digital sewing patterns are created by scanning software that converts physical patterns into a digital format, transitioning them into the virtual world;

- They offer streamlined production processes, cost-effectiveness, and minimizing wear and tear on paper patterns;

- Explore the full potential of your production stages by experiencing Audaces360 multi-solution, now available for a free trial.

In the fashion industry, various techniques are employed to create patterns for new collections.

While many students, professionals, and companies still rely on manual methods, the ever-evolving market demands, and technological advancements are driving an increasing number of fashion businesses to embrace digital sewing patterns and direct computer modeling.

This emerging trend is fueled by the numerous advantages offered by computerized modeling, including enhanced efficiency in time and material utilization. Moreover, it ensures greater precision and safety throughout the entire fashion production process.

The transition from manual to digital methods may appear daunting, but it is simpler than you might imagine.

Sumário

Keep reading to discover more about the benefits of digital sewing patterns!

What are digital sewing patterns?

Digital sewing patterns leverage software to scan physical templates and seamlessly transfer them into the virtual realm.

These patterns are meticulously crafted, captured, and transferred to a digital environment, enabling designers to visualize and modify their designs prior to physical production.

Digital patternmaking encompasses the creation and customization of garments, footwear, bags, and other accessories while providing the ability to simulate various fabrics, patterns, and colors.

These patterns can be easily shared among team members, such as pattern makers and seamstresses, facilitating seamless communication and collaboration.

This technique holds significant importance in the fashion industry as it enables companies to save time and resources that would otherwise be spent on producing physical samples.

Additionally, digital sewing patterns empower designers to explore different design options and fitting variations, leading to reduced errors and heightened accuracy and quality in the final product.

Learn more: Learn what 3D modeling is and its benefits for clothing design and production

Advantages of digitizing clothing patterns

For pattern makers or fashion brands with an existing collection of paper-based patterns, converting them into digital files is now more accessible than ever before.

Utilizing the right solution, the digitization of sewing patterns has been made simpler with the aid of modern systems and equipment.

By embracing technology, companies can capture the key points, contours, and markings of physical patterns using a camera or a mobile device and transfer them into a computer-aided design (CAD) work system.

This enables them to leverage both their previously developed projects using traditional methods and the new resources that enhance agility and precision once the patterns are digitized.

Working with digital sewing patterns offers several advantages, check out some of them below!

Simplified application of margins and notches

The process of scanning sewing patterns proves immensely valuable when it comes to applying margins and notches in fashion design projects.

This technology enables the creation of precise virtual models that can be effortlessly adjusted as needed.

With the aid of pattern scanning software, designers can easily define these crucial details, incorporating accurate margins for seams and precise finishing touches with millimeter precision.

Learn more: Learn how to incorporate digital patterns into your production

Automatic calculation of fabric alterations due to shrinkage

Another advantage is automation, which enables swift grading of patterns. By simply selecting a predefined size scale with a few clicks, patterns can be resized without the need for manual calculations.

This automation feature proves particularly valuable when it comes to calculating fabric alterations due to shrinkage. The technology takes into account the expected shrinkage rate and automatically adjusts the patterns accordingly. This ensures accurate resizing for different sizes.

Learn more: Discover the benefits of a pattern grading chart for your clothing production

Automated marking and fabric utilization visualization

A range of software solutions exists to support the digitization of clothing patterns and enable automatic marking as well as visualizing fabric utilization.

These software applications allow for the creation of virtual representations of patterns, which can then be automatically adjusted to fit the fabric more efficiently.

By leveraging automatic modeling capabilities, fashion designers and pattern makers can optimize the marking process of pattern pieces on the fabric.

Certain systems even offer automatic nesting features that consider fabric characteristics such as stretch and thread direction.

These features help minimize fabric waste by ensuring more efficient utilization. As a result, time and money are saved, as there is a reduced need for production adjustments, re-cutting, or additional fabric purchases.

Streamlined pattern modifications and time savings

Digital sewing patterns offer numerous advantages for clothing manufacturing, particularly when transitioning from manual to digital methods. This allows businesses to leverage the best of both worlds and expedite their processes effectively.

One notable advantage is the simplification of pattern modifications, resulting in substantial time savings.

Previous patterns can be reused as foundations for new projects without the need to start from scratch.

By utilizing digital sewing patterns, enterprises can reduce the time required for pattern creation, modification, and iteration. This allows for faster product development cycles, increased productivity, and improved overall time-to-market.

Learn more: What digital sketching is and how to apply it to your fashion collection

Enhanced communication among designers, stylists, and pattern makers

Digital sewing patterns serve as a powerful tool to facilitate communication and collaboration between designers, stylists, and pattern makers. With the aid of digital modeling software, accurate virtual patterns can be created and shared with team members located in different places, enabling real-time collaboration.

This means that patterns can be easily shared with stylists and pattern makers, who can view and provide direct feedback on the designs, streamlining the communication process. The ability to exchange comments and suggestions directly on the virtual patterns enhances efficiency and accuracy in the development stages.

Moreover, digital modeling fosters collaborative teamwork by allowing multiple team members to work on a project simultaneously, sharing feedback and ideas for improvement. This collaborative approach minimizes communication and production errors, leading to a more refined final product.

Precision in modeling with millimeter accuracy

Digital sewing patterns provide a significant advantage in terms of millimeter precision in modeling, allowing for the creation of highly accurate designs.

Compared to traditional paper pattern techniques that often rely on manual measurements and estimates, digital patterns offer superior accuracy. The meticulous digital modeling process ensures precise measurements and eliminates potential errors associated with manual techniques.

The millimeter precision afforded by digital sewing patterns not only results in more accurate garment designs but also helps in reducing production errors.

Design adjustments can be made with precision even before the actual project begins, minimizing the need for costly and time-consuming corrections during production.

Material cost savings

Utilizing scanning technology in digital sewing patterns enables companies to optimize and reduce costs associated with raw materials, thanks to its reduced susceptibility to errors compared to traditional modeling methods.

By minimizing errors and the need for rework, automation plays a crucial role in reducing waste. This directly impacts the quality and final price of the product, as well as the profit margin, sustainability efforts, and the overall brand image in the market.

Cloud-based storage for saved templates

Digital sewing patterns offer the advantage of storing files in the cloud, providing numerous benefits for designers and pattern makers. Here are some of them:

Seamless sharing

Saving patterns in the cloud enables effortless sharing with team members, suppliers, and customers. With a simple invitation, authorized individuals can access the patterns, fostering efficient collaboration and communication.

Automated backup

Storing patterns in the cloud ensures automatic backup and protection. The files are securely stored on reliable servers, safeguarding them from loss or damage that may occur with local equipment.

Remote accessibility

Cloud storage allows easy access to pattern files from anywhere with an internet connection. Designers and pattern makers can work from various locations, such as the company office or home office while maintaining productivity.

Efficient space utilization

Saving patterns in the cloud eliminates the need for physical storage space. Instead of relying on shelves or folders to store paper patterns, the digital format allows for efficient organization and easy access to pattern files.

Learn more: How does digital fashion design work and what are the benefits for the clothing industry?

Key technologies for digital sewing patterns

The textile and clothing industry faces growing competitiveness and the need to deliver products that combine quality and affordability.

To meet these demands and drive productivity and efficiency, investing in new technologies is crucial. Digital sewing patterns offer a solution to expedite processes and enhance the accuracy and safety of production.

The transformation of physical patterns into digital ones is best achieved through the utilization of digitizing tables or frames combined with intelligent systems that operate based on photographs. These technologies enable numerous benefits.

Internal markers are employed to detect markings such as notches, while a minimum photo resolution of five megapixels and the activation of the device’s flash are necessary to ensure optimal results.

Additionally, advanced systems automatically identify elements such as thread direction and notches (both internal and on the contour). Moreover, innovative tools are available for scanning large patterns, catering to complex designs like party dress models or upholstery development.

Once the scanning process is completed, the employee can conveniently transfer the photo from the camera to the computer.

Subsequently, the pattern maker gains access to a digital file that enables the manipulation and development of new pattern bases without compromising the original model.

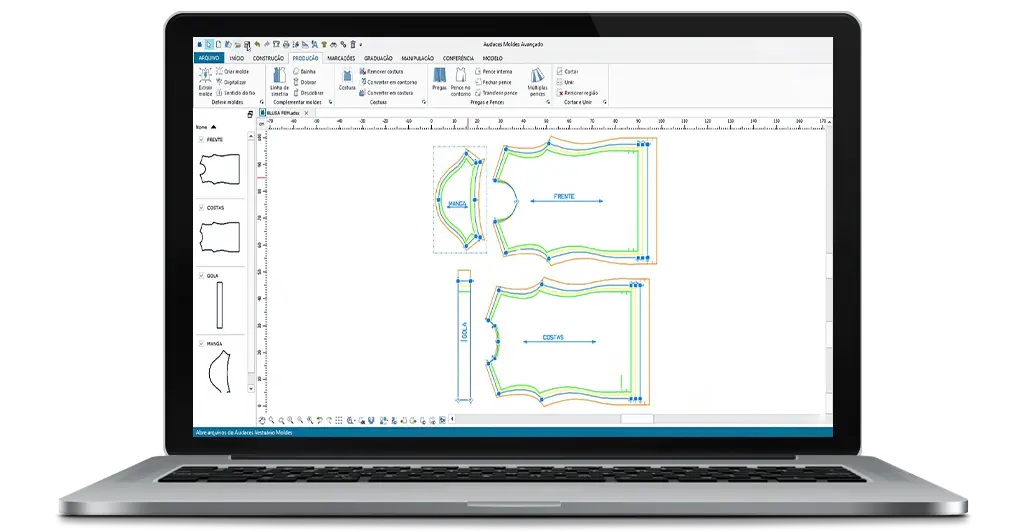

Leading CAD systems like Audaces Pattern provide a comprehensive environment where professionals can freely modify and refine the pieces.

Through the intuitive interface and an array of creative and flexible tools exclusive to the Audaces360 multi-solution, the pattern maker can achieve optimal outcomes using the mouse cursor.

By harnessing these technologies, companies can accelerate their internal processes and unlock new possibilities in digital sewing pattern development.

How to digitize clothing patterns with Audaces Digiflash?

Are you looking to enhance the digitization of your sewing patterns? Audaces Digiflash is here to assist you.

Audaces Digiflash is software designed specifically for digitizing clothing patterns, enabling pattern makers to transform their paper patterns into digital files compatible with cutting machines and printers.

With this powerful tool, you can capture images of physical molds and swiftly digitize them with exceptional precision.

The software also offers advanced editing capabilities, allowing you to easily adjust measurements and create new pattern variations. This streamlines the pattern modification process and enables the creation of innovative designs.

To further optimize your digitization workflow, Audaces also offers the Digiflash Device — a specialized equipment that works seamlessly with the Digiflash software to convert physical molds into digital versions.

By utilizing the Digiflash Device, you can significantly enhance precision and efficiency, eliminating the potential for measurement and calculation errors commonly associated with manual modeling.

The Digiflash software and Digiflash Device are part of a comprehensive suite of Audaces solutions, encompassing additional software and machinery for pattern making, marking, and automated cutting.

By integrating these tools into your production process, you can realize notable benefits, including cost reduction, time savings, and the ability to create highly accurate and sophisticated pattern designs.

Learn how to use Audaces Digiflash for digital sewing patterns

To successfully digitize your sewing patterns using Audaces Digiflash, follow these steps:

- Connect the Digiflash Device to your computer using the USB port;

- Launch the Digiflash software that is already installed on your device;

- Place the paper template onto the base of the Digiflash Device;

- Press the scan button on the Digiflash Device to capture an image of the pattern;

- Within the software, select the “Import” option and choose the scanned image of the pattern;

- Choose the “Create shapes” option and utilize the drawing tool to trace the lines of the pattern;

- Save the digitized pattern in a compatible format for your cutting machine or printer;

- And that’s it!

Would you like to delve deeper into this topic and learn more? We have an infographic available for free, providing a step-by-step guide on digitizing clothing patterns. Download now!

FAQ

Digital sewing patterns are created by using software to scan physical pattern templates and convert them into digital files, allowing for virtual manipulation and use.

Digital sewing patterns offer several advantages, including easy application of margins and notches, automatic calculation of fabric alterations due to shrinkage, automatic fittings and visualization of fabric utilization, simplicity in changing patterns, time savings, and more.

Connect the Digiflash Device to the computer via USB; open the Digiflash software; insert the paper template into the device base; press the scan button to capture the template image; select the scanned image, trace the template lines using the drawing tool; check the accuracy of scanned measurements; make any necessary adjustments; save the pattern in a supported format.