Summary

- Clothing manufacturing involves a structured process that transforms an idea into a finished product ready for sale.

- Understanding how it works helps brands avoid mistakes, reduce costs, and make better decisions.

- Get monthly fashion insights straight to your inbox. Subscribe to our newsletter!

Bringing a clothing idea to life is exciting, but it also raises questions. How do manufacturers turn sketches into real garments? What happens behind the scenes in a factory? And how can you make the right decisions when you’re producing for the first time or scaling an existing brand?

Understanding the apparel industry helps you plan better, avoid surprises, and run your business with confidence.

In this guide, we’ll explore how it truly works. We’ll cover the production stages, the most common challenges brands face, and the different types of manufacturing available.

Ready to dive into the process? Happy reading!

Sumário

Do you know how a clothing manufacturing business works?

Everything begins long before production, with planning, research, and defining the product vision. At this stage, brands think about their audience, materials, fitting expectations, and pricing.

Once the plan is ready, the technical work begins. Teams create patterns, select fabrics and trims, and sew and test prototypes. This is where ideas turn into tangible samples!

After approval, the product moves into full production. Cutting, sewing, finishing, labeling, and quality control all work together in a coordinated workflow to produce consistent results.

Finally, it’s time to package and send the clothes to their destination. This could be a warehouse, a store, or directly to customers.

Understanding this process gives business owners clarity, confidence, and the ability to make better decisions as they grow.

Challenges faced in clothing manufacturing

Although the fashion industry is full of opportunities, apparel manufacturers face several ongoing challenges:

Lack of skilled labor

One of the biggest difficulties in the industry is finding qualified professionals. Sewing, pattern making, and fabric handling require technical knowledge that takes time and training to develop.

As many experienced workers retire, fewer new professionals enter the field, creating a significant gap in skilled labor.

To address this gap, the industry must reconsider how it treats and recognizes sewing professionals.

Improving workplace conditions, ensuring fair pay, and investing in ongoing development can help make the position more appreciated.

Competition with imported products

Imported clothing often arrives on the market with competitive pricing, particularly from countries where production costs are lower.

This can put pressure on garment manufacturers operating in local markets. Especially when buyers focus only on price instead of value, quality, or delivery reliability.

To remain competitive, many domestic fashion brands focus on agility, flexibility, customization, and faster turnaround times. Local production allows brands to respond more quickly to trends and restock faster, reducing inventory risks.

Offering quality apparel becomes another differentiator factor. While imported products may be cheaper, local manufacturers can offer better materials, precise fit, and better quality control. These features make the final product more appealing for consumers and premium markets.

Sustainability and responsible production

Businesses are facing increasing pressure to use eco-friendly materials, reduce waste, and adopt ethical production practices. Consumers today want transparency, and brands must prove that what they produce is both high-quality and responsible.

For apparel production, this shift creates both challenges and opportunities.

Sustainable fabrics, certifications, and waste management can increase production costs. On the other hand, manufacturers that adapt gain market relevance and open doors to partnerships with conscious brands.

Read more: How to achieve cleaner production in clothing manufacturing?

Innovation and technology

Tools like digital pattern making, automated cutting machines, 3D prototyping, and integrated production systems help scale operations efficiently.

For those who offer manufacturer services, innovation is the key to overcoming manual limitations and improving consistency. With automation and digitalization, teams work faster, communication improves, and decision-making becomes more strategic.

Factories that embrace technology often reduce costs and speed up production cycles without sacrificing quality.

Read more: Discover the main types of automation transforming fashion

Main stages in clothing manufacturing

Design

The design stage is where ideas take shape. Designers explore colors, fabrics, silhouettes, and styles that align with the brand’s identity.

At this point, every decision helps define the direction of the collection and how it will stand out.

Sketches, mood boards, fabric swatches, and technical notes guide the creative process and prepare the groundwork for what comes next. This stage sets expectations for function, style, and cost, ensuring the product vision is aligned with business goals.

Read more: 7 steps to develop your fashion collection plan

Development

Once the design is ready, the development stage begins. Here, technical details become essential.

It’s the moment to source materials, select trims, and document specifications. Accuracy matters, because every detail influences the final cost, quality, and timeline.

During development, teams work closely to refine measurements, fabric behavior, and construction methods. This step ensures the product is feasible for manufacturing and meets performance expectations.

The clearer the development phase, the smoother the transition into sampling and production.

Pattern making

This step defines the fit, shape, and structure of the garment. Skilled pattern makers consider fabric stretch, seam allowances, ease, and body proportions to ensure comfort and accuracy.

After the first pattern is ready, it often goes through adjustments based on fit tests and sample reviews. Digital pattern-making systems can accelerate this process, improve precision, and reduce material waste.

Read more: Explore clothing pattern making techniques for your production

Cutting

Cutting marks the moment the fabric moves into production. Precision matters, because even small errors can impact fit, consistency, and material usage.

Some teams cut manually with skilled operators. Meanwhile, others rely on automated spreading and cutting machines to improve accuracy and reduce waste.

Before cutting, the team spreads and inspects the fabric to spot defects or distortions. After, they label and bundle each piece, so the next stages stay organized and efficient.

Good preparation here keeps the sewing line productive and prevents unnecessary delays later in the process.

Read more: 7 pro tips on how to cut fabric for garment manufacturing

Sewing and finishing

Here, skilled operators assemble the garment using the appropriate construction methods, stitches, and machinery for each type of fabric.

Quality checks often happen during sewing to identify issues early and prevent larger production errors.

Then, the garment goes through the finishing stage. It can include pressing, trimming loose threads, attaching labels, and adding any final touches.

Ready to make your fashion business a success? Get all the tips you need in our exclusive guide. Download it for free now!

What types of clothing manufacturing exist?

Clothing manufacturing can follow different formats depending on the brand’s goals:

Private label production

This model allows brands to create exclusive products under their own name.

The manufacturer produces garments based on the brand’s designs, identity, and technical requirements. It’s a way to have full creative control and the opportunity to build a unique market positioning.

However, this approach often requires planning, sampling time, and clear communication between both sides.

For businesses focused on building long-term identity and recognition, this model becomes a powerful strategy.

Made-to-order manufacturing

In made-to-order production, manufacturers only start creating a garment after receiving a confirmed request. This model reduces inventory risk and aligns production with real demand.

For brands that prioritize customization, it can be the ideal method because it supports flexibility and avoids overproduction.

The drawback is that production times may increase, especially if you source materials after the order comes in. However, when managed correctly, this model strengthens customer engagement and supports sustainable practices by reducing waste and unnecessary stock.

Manufacturing for resale

It focuses on producing ready-made items that brands or retailers buy and resell under their own name.

This model appeals to companies that want speed and simplicity since they don’t need to develop original designs. It works well for businesses entering the market or testing new product categories.

The trade-off is less exclusivity, since multiple buyers may sell similar styles. Still, for brands focused on quick turnover, affordable pricing, or fast trend response, it offers strong commercial opportunities.

Manual cutting vs automated cutting: Which one is better?

Manual cutting has been part of the industry for decades and relies on the experience of the operator. This method offers flexibility, especially for small batches or delicate materials that require extra attention.

However, it leaves room for human error, inconsistencies, and material waste.

Automated cutting systems take a different approach. They use digital patterns and precise equipment to ensure accuracy and repeatability.

Every cut follows the exact specifications, which strengthens consistency across all sizes and styles. Automation also optimizes material usage, reducing waste and lowering production costs over time.

When comparing both methods, automation stands out for precision, scalability, and waste reduction. In today’s competitive market, it offers a clear advantage and supports long-term growth.

Read more: 6 benefits of a cutting room for your fashion manufacturing

How can technology support daily operations in clothing manufacturing?

Technology streamlines key tasks and brings more organization to the production workflow. Digital tools help reduce repetitive work, eliminate manual errors, and create a clear structure from design to production.

It also strengthens collaboration. Designers, pattern makers, and production teams can share updates instantly, ensuring everyone works with accurate and current data. This alignment helps reduce miscommunication and delays, especially when teams manage multiple styles or suppliers.

As processes become faster and more predictable, manufacturers gain better control over lead times and planning.

Read more: How can fashion technology boost your production?

Manage your clothing manufacturing process with Audaces360

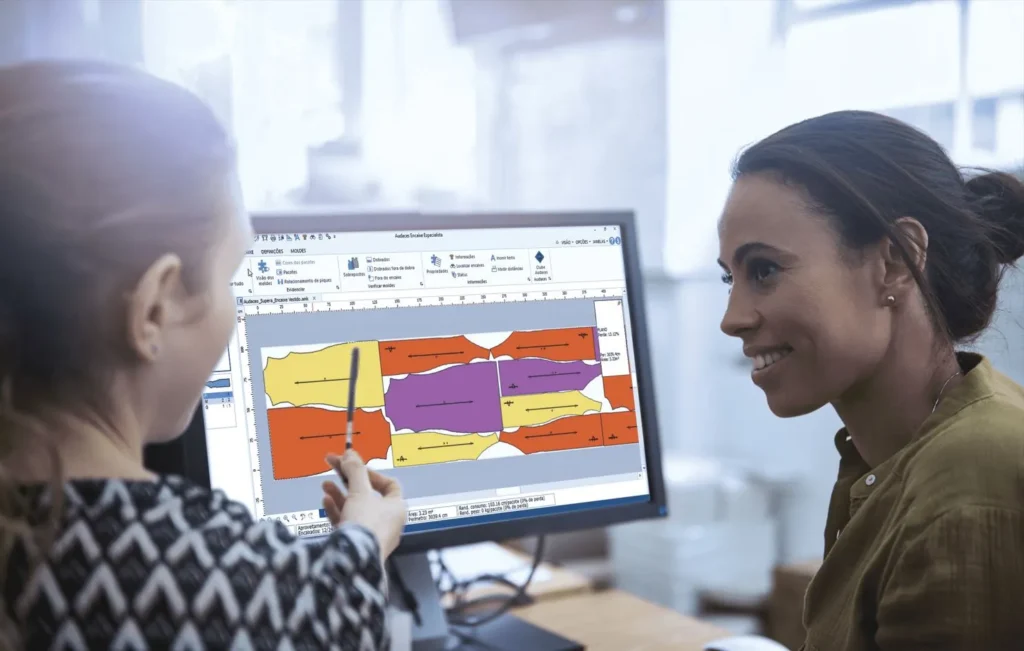

Audaces360 integrates cutting-edge digital innovations to optimize workflows in the textile and apparel industry.

It caters to companies of all sizes and types, offering the flexibility to scale with your business needs.

All solutions were carefully developed to address the specific challenges of the field. They streamline the design and production processes, saving valuable time and resources.

The platform boasts a comprehensive range of functionalities, including pattern making, marking, collection management, vector drawing, and 3D creation.

In addition, a fashion Artificial Intelligence to assist you along the way.

Follow the lead of Amibo, a Serbian brand known for its pajamas, underwear, and outdoor collections. The company started a digital transformation journey with Audaces to make its processes faster and more sustainable.

See how they did it!

Discover Audaces360 and unlock a world of possibilities for fashion design and production. Explore our comprehensive suite of solutions today!

FAQ

They include lack of skilled labor, competition with imported products, sustainability, and innovation.

The main stages in clothing manufacturing are design, development, pattern making, cutting, sewing, and finishing.

The most common are private label production, made-to-order manufacturing, and manufacturing for resale.