Summary

- A modern cutting room streamlines fabric usage, reduces waste, and ensures higher precision in garment production.

- By automating processes, production managers can increase efficiency, optimize resources, and improve delivery times.

- Discover how a cutting room can boost your fashion manufacturing!

In fashion manufacturing, every step makes a significant difference in costs, timelines, and quality. Among these stages, the cutting room plays a central role that defines the success of the entire production process.

Traditionally, many factories managed cutting with manual methods, relying heavily on experienced workers and manual marking. While this approach works, it often results in inconsistencies, higher waste, and slower production cycles.

If your goal is to maximize productivity while maintaining quality, understanding the benefits of a cutting room is essential. In this article, we’ll explore the key advantages that will help you take your company to the next level.

Happy reading!

Sumário

What is automated cutting?

Automated cutting is the process of using machines to cut fabrics with the help of advanced software. Instead of relying on hand-guided tools, the system reads the pattern directly from a CAD file and follows it with high precision.

This method allows companies to cut dozens of layers of fabric at once, saving time and resources. It reduces human error and guarantees consistency, especially when producing large volumes of garments.

What does the cutting department do?

The cutting department plays a central role in garment manufacturing. Its main responsibility is to transform fabric rolls into ready-to-sew pieces by following patterns and production orders. Without this step, the sewing team cannot start their work.

How does a cutting order work?

A cutting order is the document or system record that organizes everything needed for the cutting stage. It specifies the fabrics, markers, sizes, and quantities that operators must prepare. In many ways, it acts as a roadmap to guide the team.

Learn more: How can a good cutting plan transform your production?

What is the salary of a cutting machine operator?

The salary of a cutting machine operator varies depending on the country, industry, and level of experience. According to Glassdoor, entry-level operators usually earn closer to the local minimum wage. Meanwhile, experienced professionals can earn considerably more.

In the United States, for example, a cutting machine operator typically earns between $30,000 and $45,000 per year. In countries with lower labor costs, such as India or Brazil, average salaries are lower.

How much does an Audaces cutting machine cost?

The price of an Audaces cutting machine depends on factors like additional features. Since every business has different needs, the investment can vary between companies.

To get an accurate figure, the best option is to speak directly with an Audaces consultant. They will analyze the company’s production volume, fabric types, and growth plans before preparing a customized quote. This ensures the investment delivers the best possible return!

Learn more: 6 benefits of automatic cutting for your fashion business

6 benefits of an automated cutting room

An automated cutting room can transform the way fashion companies produce garments. Here’s how:

1) Quality in cut patterns

Consistency in pattern cutting is essential to guarantee that garments fit and look as planned. Automated cutting machines follow digital files with exact precision, ensuring every piece comes out identical.

This accuracy reduces defects, minimizes rework, and improves the overall quality of the collection.

Learn more: 4 reasons you should invest in a cutter room for fashion

2) Creative freedom

Designers often limit their ideas because they worry about production complexity. With automated cutting, those limits shrink, since the system can handle intricate shapes, curves, and details with ease.

By making production more flexible, automation opens the door for collections that truly stand out in the market. Creativity flows, and innovation becomes part of everyday work.

3) Higher productivity with fewer resources

Automation means cutting more garments in less time. Machines can process dozens of fabric layers simultaneously, which multiplies output without requiring more staff. They reduce the need for overtime or additional workers to meet deadlines.

It also helps factories respond quickly to changes in demand, keeping production on schedule.

At the same time, automated systems optimize fabric use, lowering waste and cutting costs. Companies produce more with fewer resources, which directly improves profitability.

Want to discover all the benefits the Audaces Automated Cutting Room can bring to your business? Download our exclusive free guide now!

4) Professional skill development

Technology doesn’t replace workers: it changes the kind of skills they need. Operators learn how to manage machines, read digital files, and optimize production orders.

These technical skills add value to their professional profile, making them more competitive in the job market. For companies, it means having qualified staff who understand both technology and production.

Fashion manufacturers build stronger teams capable of managing advanced processes by investing in training.

5) Equipment integration

An automated cutting room rarely works alone. It integrates with spreading machines, CAD systems, and production planning software to create a smooth flow.

Integration eliminates communication gaps, reduces errors, and ensures the alignment of all steps of production. The result is a connected factory where efficiency grows at every stage.

Learn more: 7 key factors to look for in the best fabric cutting systems

6) Operational efficiency

Machines follow precise schedules, consume the right amount of fabric, and deliver predictable results. It’s easier for managers to plan, control costs, and meet deadlines. Instead of firefighting errors, they focus on strategy and continuous improvement.

Operational efficiency also means faster turnaround times. This helps companies respond quickly to customer demands and stay ahead of competitors.

Learn more: How to overcome slow cutting in your apparel manufacturing?

Why is it worth digitizing the cutting process in fashion manufacturing?

Digitizing the cutting process ensures that fashion businesses keep pace with a fast-changing industry. Manual methods can no longer deliver the accuracy, speed, and cost control required to compete.

Companies have the power to gain the ability to cut precisely, save fabric, and accelerate production. These improvements directly impact profitability and customer satisfaction.

In the long run, digital cutting creates a foundation for sustainable growth. It reduces waste, empowers workers with new skills, and keeps collections aligned with market expectations.

Learn more: Find out which 4 cutting tools are worth your investment

When you think automated cutting, think Audaces Cutting Room

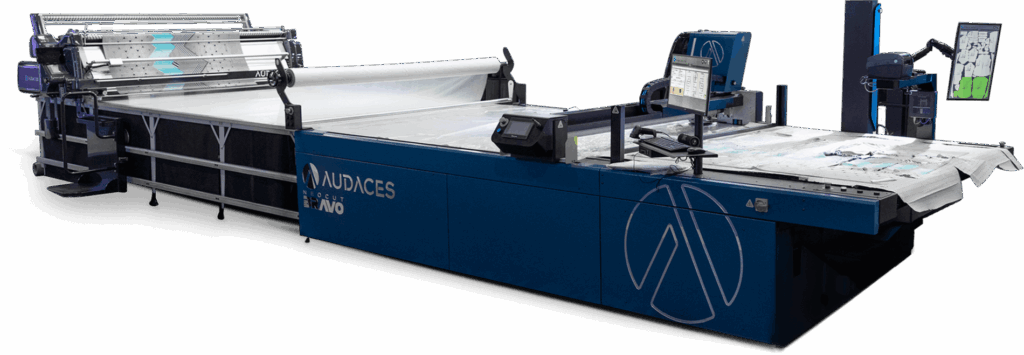

Audaces Neocut Bravo

Achieve on-time production aligned with your business goals with this Audaces Neocut Bravo automatic cutting machine.

The centerpiece of Audaces Cutting Room, it delivers accurate data automatically, empowering informed decision-making.

Additionally, continuous monitoring of process conditions allows for remote maintenance, swift issue resolution, and keeps your production line running smoothly.

The machine is strong and can handle heavy materials easily. Its precise cutting also takes care of delicate fabrics, providing zero-spacing and high-quality results for every project.

Audaces Premium

Streamline your production with the Audaces Premium automatic spreader. This innovative machine empowers you to program multiple fabric spreads for the same day with just a tap on its touchscreen.

Boost your project and company’s dynamism and autonomy, leading to higher production standards and ultimately, increased profits.

Audaces Premium also ensures even fabric tension and edges, guaranteeing consistent quality in every fabric layer.

Audaces Pratica

Unleash versatility in your cutting room with the Audaces Pratica spread table. This multi-purpose solution adapts to various spread sizes, maximizing your production capacity.

The innovative insufflation function allows for customized layouts, perfectly aligning with your company’s specific needs.

Plus, Audaces Pratica seamlessly integrates with Audaces Premium spreader for a truly streamlined workflow.

At first, this uniform company thought growth had to come before automation. But the Audaces Cutting Room proved they could achieve both together. See how in this success story!

FAQ

Automated cutting is the process of using machines to cut fabrics with the help of advanced software.

Its main responsibility is to transform fabric rolls into ready-to-sew pieces by following patterns and production orders.

It specifies the fabrics, markers, sizes, and quantities that operators must prepare. In many ways, it acts as a roadmap to guide the team.