Summary

- Pattern making is at the core of the development stage in fashion manufacturing, as it connects creation with production.

- Performing it correctly and precisely ensures first-rate garments, with minimal waste, that satisfy consumers.

- Use technology to your advantage to achieve high-quality patterns. Try Audaces360 solutions for pattern makers for free!

Pattern making tools are essential elements found in every apparel manufacturing company.

They need to be carefully selected and of superior quality. Additionally, it is very important to properly maintain them. This will ensure accuracy and excellence in project outcomes.

To guide you in making the best choices, we have created a detailed guide on the subject with professional tips.

Enjoy your reading!

Sumário

Why invest in good pattern making tools?

Good pattern making tools ensure accurate measuring and cutting, resulting in garments that fit as planned. This precision minimizes errors and reduces the need for rework, saving time and resources.

They lead to well-constructed garments with the right drape, consistent sizing, and a professional appearance. Therefore, enhancing brand reputation and customer satisfaction.

Choosing efficient tools for pattern making streamlines the development process. This helps companies create new designs quickly and meet customer needs. It also allows them to stay current with market trends.

All of this while minimizing fabric waste, leading to the use of less resources and a more sustainable production process. This contributes to overall cost savings and environmental responsibility.

Moreover, pattern making tools are durable and can last for many years. It makes investing in high-quality ones a strategic decision.

When choosing your tools, keep in mind that they can significantly improve garment quality, efficiency, and cost-effectiveness. It is an investment that pays off in the long run.

Learn more: Understand the importance of a pattern maker for fashion manufacturing

6 pattern making tools every pattern maker should use

These are some of the essential tools that you should consider adding to your workspace:

Pattern making ruler

A pattern making ruler has markings that are specifically for creating patterns. It features accurate scales, straight edges, and curves that are essential for drafting precise patterns.

Set square

A set square, also known as a drafting square or try square, is a tool used to create straight lines and right angles.

It is essential for drawing accurate lines and ensuring that pattern pieces align correctly.

French curve

It is a set of curves that are used to create smooth, flowing lines on patterns. It is particularly useful for drafting armholes, necklines, and other curved shapes.

Scissors

Sharp scissors are essential for cutting out pattern pieces from paper, fabric, or other materials. Choose scissors with a comfortable grip and sharp blades to ensure precise cutting.

A valuable tip is to have a separate pair of scissors for each type of material and use them only for that purpose.

Each material has unique properties that can affect the cutting action of scissors. For instance, paper scissors are designed for thin, delicate materials like paper. While fabric scissors have sturdier blades to handle different types of fabric.

Using the same scissors for both types of materials can lead to dull blades and uneven cuts.

By using dedicated ones, you extend their lifespan and cutting performance.

Learn more: Learn how to create denim patterns for your next collection

Rotary cutter

A rotary cutter is a circular blade that cuts through multiple layers of fabric at once. The continuous rolling motion allows for faster cutting compared to scissors, especially for long, straight cuts.

The precision and efficiency that this tool guarantees streamlines the cutting of garment samples, for example.

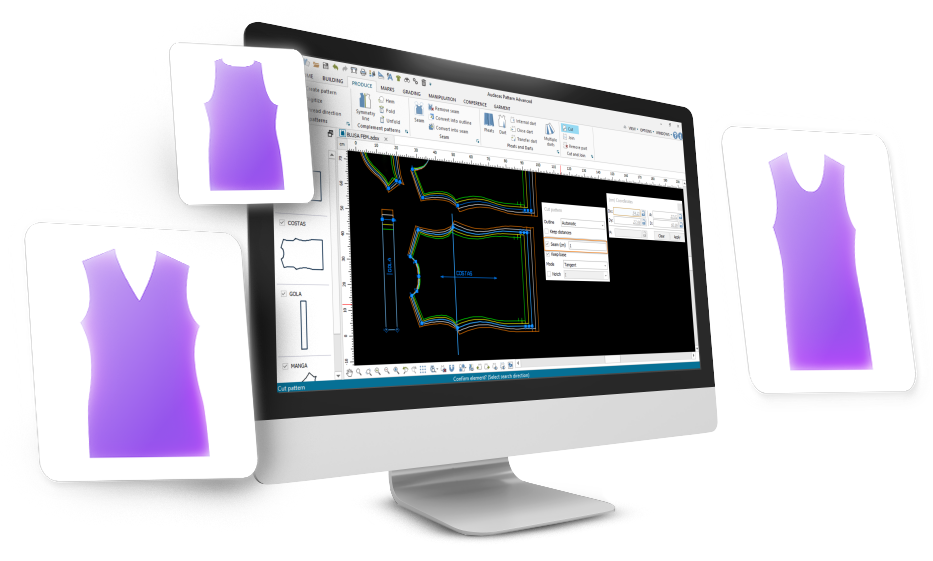

CAD/CAM systems

Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems are software used to create digital patterns.

These systems offer precision, efficiency, and the ability to store and modify patterns easily. They offer tools to simplify the development of patterns, automating repeating tasks and the grading process.

Other tools

In addition to these essential tools, pattern makers may also find other helpful ones, such as:

- Pattern paper: this is a special type of paper for drafting patterns. It is typically smooth, durable, and translucent, allowing for easy tracing and marking.

- Pattern tracing wheel: a tracing wheel is a tool to transfer pattern markings from one piece of paper to another. It is a more precise and efficient way to transfer markings than using a pencil.

- Pattern notcher: a pattern notcher is a tool to create small notches in the edges of pattern pieces. These notches serve as reference points for sewing and assembly.

- Tape measure: a tape measure is essential for taking body measurements and ensuring that patterns fit the wearer correctly.

By having these essential tools on hand, pattern makers can create accurate patterns that ensure high-quality garments.

Learn more: 6 types of pattern making courses to enhance your skills in fashion industry

Benefits of using technological pattern making tools

Technology allows for no longer relying solely on paper to create and store patterns. Check out some of the advantages of using digital tools for pattern making:

Speed and precision

Digital pattern making tools can automate many of the tasks involved in creating patterns. This can save time and improve accuracy.

Creating digital patterns in specialized software is faster than manual methods. This is because you can count on automatic size tables and robust design tools and features.

These solutions can automatically adjust patterns to different sizes, ensuring consistency and accuracy across all sizes offered.

They also provide precise measurements and straight lines. This eliminates potential errors caused by manual tools like rulers and French curves.

Zooming in on specific areas enables detailed adjustments and ensures precise positioning of darts, seams, and other details.

Learn more: Discover the benefits of a pattern grading chart for your clothing production

Material savings

Technological solutions allow for more precise pattern creation compared to manual methods. Precise patterns translate to less fabric needed for corrections due to inaccurate sizing or improper fit.

With traditional methods, making changes often requires redrawing parts of the pattern. It can lead to wasted paper and potentially wasted fabric if adjustments are not successful on the first attempt.

On the other hand, digital pattern making tools allow for virtual adjustments. It helps minimize the risk of creating unusable patterns and reduces resource waste associated with trial and error.

Creating digital patterns also contributes to saving material related to the cutting process. This is because paper-based methods involve manually laying out pattern pieces on fabric. It often leads to wasted space and leftover fabric scraps.

Digital pattern solutions can usually be integrated with marking software. This is perfect for automating the marking process, minimizing gaps, and maximizing fabric use.

Learn more: Advantages of using free sewing patterns and where to find them

Increased efficiency

Pattern making software automates repetitive tasks like drafting base patterns and grading for different sizes. This is important to free up the pattern maker’s time for more creative and strategic work.

Also, digital storage helps you save time because it’s easier than searching for physical copies.

Furthermore, pattern making software facilitates collaboration and reduces the risk of errors. Teams can work on the same pattern simultaneously with real-time updates. This significantly improves handoffs and communication between team members.

Another advantage is the ability to track revisions and save different versions of a pattern. It prevents accidental overwriting and allows for clear communication of changes.

Additionally, there are software options that offer error checking, identifying potential issues like overlapping lines or incorrect measurements for correction.

Finally, some digital tools offer integration with 3D programs. Designers and pattern makers can simulate how the garment will drape on a virtual model. This allows for digitally sewing your patterns and identifying potential fit issues early on.

Learn more: 5 benefits of 3D modeling software in your apparel company

Reduced losses and misplacements

Those who work with physical paper patterns know how much work it is to organize them. They can easily be misplaced, damaged, or even lost entirely. This means a lot of wasted time and effort.

As a solution, digital storage on computers or cloud platforms eliminates this risk. Patterns are readily accessible and can be easily backed up to prevent accidental deletion.

Digital storage also allows for efficient organization of patterns with folders, minimizing the risk of lost or forgotten patterns.

Discover all the pattern making tools from Audaces Pattern

Audaces Pattern is a powerful solution that transforms pattern making in the fashion and apparel industry.

With its dynamic and innovative approach, the software enables the development of high-quality and precise patterns. This includes projects of any complexity.

One of the main advantages of is its seamless integration with the digital environment. Users can initiate the pattern making process directly on the computer, with no need to work with paper and pen.

This not only streamlines the process but also reduces errors and rework, ensuring flawless execution of the collection.

Audaces Pattern offers advanced features such as digitizing existing patterns or extracting pre-patterns from Audaces Fashion Studio. This means you can leverage pre-existing designs, saving time and resources.

Its advanced features make it an essential ally for fashion and apparel professionals seeking quality, efficiency, and innovation in their pattern making processes.

By combining technology with expertise in the textile industry, Audaces Pattern ensures exceptional results in every garment.

Facing difficulties in pattern making or marking processes? Download our free e-book now!

FAQ

Good pattern making tools ensure accurate measuring and cutting, resulting in garments that fit as planned. This precision minimizes errors and reduces the need for rework, saving time and resources.

Pattern making ruler, set square, French curve, scissors, rotary cutter, and CAD/CAM systems.

Speed and precision, material savings, increased efficiency, and reduced losses and misplacements.

2 Responses

i need all the Pattern making ruler, set square, French curve, scissors, rotary cutter, and CAD/CAM systems. where can i get them from in Uganda?

Hi Irene,

We’re a tech company excited to introduce our CAD/CAM systems! A specialist will reach out via email to better understand your needs.

Thank you for your interest!