Summary

- What is PPC? Have you heard of this solution for efficiently controlling the processes of a production chain?

- It ensures a proper flow through procedure management and control

- Audaces can help you achieve excellent performance throughout the creation and production process. Get the free trial and discover how!

What is PPC? Some may wonder, not realizing that production control stands as one of the most effective means of resource management.

PPC, along with other similar processes, ensures a comprehensive understanding of a company, industry, or fashion business’s products, services, and goods.

However, managing the diverse processes within a production chain necessitates the development of efficient, agile strategies and tactics tailored to the unique context of each business.

Well, in this context, PPC (Production Planning and Control) emerges as a solution to this challenge, as it is a tool focused on controlling and planning within the production chain.

Sumário

Would you like to learn more about this topic? Continue reading to explore the concept of PPC, its functions and benefits, and how to apply it practically and efficiently in fashion manufacturing.

We hope you enjoy it!

What is PPC (Production Planning and Control)?

The term PPC stands for Production Planning and Control, which is a set of tools, systems, and instructions used to coordinate production operations in industries.

This planning system comprehends multiple departments within an industry, including finance, logistics, planning, production, distribution, and more.

This comprehensive involvement of all production areas is essential for effective production control.

What is the role of PPC?

The primary function of PPC is to ensure the smooth flow of production processes.

It happens through the management, monitoring, and control of procedures, people, machinery, and technologies involved in them.

In the fashion industry, PPC enables the production department and designers to create a new range of products with precise specifications, determining the exact number of fabrics and trimmings that will be used, along with the time allocated to each stage.

Many companies employ PPC as a strategy. Medium and large-sized companies establish a sector responsible for production planning and control due to the high volume to be produced and the often-tight deadlines.

It’s essential to understand that, much like in any other industry, in fashion manufacturing, PPC encompasses the entire production process, from the creation and development of new collections to the dispatch of products.

What are the objectives of PPC?

As a comprehensive management process encompassing the entire production chain, PPC has a set of well-defined objectives.

Naturally, its primary goal is to ensure that operational flow aligns with the schedule. Moreover, other key objectives include:

Scheduling production

This objective addresses the question “when to produce?” and involves assessing production demand while determining when each product within the demand will undergo production.

In the realm of clothing manufacturing, this entails evaluating the total pieces in a collection and scheduling their progression through technical processes, cutting, manufacturing, and distribution.

Determining production resources

Similar to the first objective, the second objective of PPC addresses the question “how much and where to produce?”.

In industrial settings, this control is crucial as it dictates the allocation of inputs, the production capacity of each machine, and the workforce required for the process.

Learn more: What is takt time and how to calculate it in your company?

Organizing production order

Determining the production order, or “in what order to produce?” is another critical objective and function of production control and planning.

This level of control is indispensable because, especially in industries and clothing manufacturing, the sequence of operations significantly impacts the final outcome.

Monitoring production

Lastly, PPC also aims to address the question, “Is the execution following the initial plan?”

After all, as important as determining the production flow is ensuring that it aligns with the plan.

This allows for clear and decisive last-minute decision-making and the identification of bottlenecks and obstacles in production.

Learn more: Explore the best fashion software options for your company

What are the stages of PPC?

Because it’s a complex and comprehensive methodology, production planning and control occur in several stages.

Do you know what they are? To help you understand what is PPC and how its functions wrok precisely, we’ve summarized all of them below:

Demand forecasting

As the name suggests, the first stage of PPC is about creating a production estimate based on past data from the sales and logistics departments, as well as customer purchasing behavior.

This marks the foundation of a well-structured PPC, as it allows for organization based on production capacity.

Determining production capacity

Defining production capacity is crucial in PPC because its relationship with demand forecasting influences the order, sequence, and production volume, which are key PPC objectives.

Therefore, the second stage involves determining the industry’s/fashion business’s production capacity to gain control over the quantity of raw materials, inputs, operations, time, personnel, and other factors involved in the production line.

Learn more: Get to know what GTIN is and its importance for the clothing industry

Aggregate Production Planning (APP)

This is a more technical stage that involves defining production strategies for a specific period of time. APP is a document that contains information such as:

- Monthly stock and production volume

- Production capacity for the period

- Processes based on the industry’s production chain

- Financial information (unit value, contracts with suppliers, and logistics).

Master Production Schedule (MPS)

MPS is another strategic document, but its purpose is to organize short-term production.

Through it, the manufacturing company analyzes and allocates its resources to meet the demand for the period, with a focus on priority demands.

Detailed Production Scheduling (DPS)

This is the stage of control and management of actual production, the shop floor. During this stage, factors such as:

- Necessary materials

- Inventory organization

- Sequence and order of production

- Resource release when available.

Production control

Finally, once all the planning is complete, it’s time to control production, ensuring that everything aligns with what was originally planned.

Efficiency analyses are paramount at this stage, as the examination of generated data can lead to significant decision-making insights for production.

How does PPC work in fashion manufacturing?

Many believe that PPC in fashion simply involves documenting everything that happens with the production of each product and then transferring this data to a reference spreadsheet.

However, the answer fot the question “what is PPC” represents much more than that!

Planning and controlling production in fashion manufacturing means designing, organizing, and coordinating all the resources, machinery, tools, and products involved in the production process.

From the moment an order is placed, a delivery date is defined. Then, the analysis of requirements is conducted based on the checklist below:

- What is the design for this demand? Is there one already defined?

- What type of raw materials will be needed for the production of the products? What is the delivery time?

- Will third-party labor be required? Cutting? Adjustments? What is the delivery time for these suppliers?

- Who will be responsible for each stage?

- Which machine/tool will be used at each stage?

- How much time will the product spend at each of these workstations?

- Are there pre-finishing processes? Coating? Waterproofing? Labeling?

- Will these processes be done in-house or outsourced? How long does this procedure take?

- After the product is manufactured and the services are completed, how will it be packaged and dispatched?

- It’s always important to consider adding some extra time as a buffer at each stage of the process. This buffer period serves as a safety zone to correct any potential production errors.

Every single stage of the process requires a time projection. Only in this way can a realistic delivery deadline be communicated that is free from unforeseen issues.

In summary, PPC in fashion and textile manufacturing involves planning, organizing, and coordinating all the processes, resources, machinery, and people involved in the production of your collections.

What are the benefits of adopting PPC?

As a methodology and tool specifically designed for production control and management, PPC offers numerous advantages to the industrial sector and the fashion industry.

Here are the key benefits:

- Effectively plans and controls production

- Manages and organizes the production flow within the production chain

- Organizes raw materials and necessary inputs for production

- Facilitates decision-making, especially last-minute decisions

- Reduces costs associated with process errors and rework

- Speeds up production and enhances operational accuracy

- Provides metrics and indices regarding productivity

- Optimizes management processes overall.

How can Audaces technology assist in production planning and control?

The volume of information related to the production process managed in PPC is enormous. Managing production without the aid of intelligent software and applications is practically impossible.

These tools are essential for maintaining effective, simplified, and agile organization. Deadlines are becoming increasingly tight, and there’s no time to waste on errors. Therefore, it’s vital to plan and manage your fashion manufacturing with precision.

To ensure excellent performance throughout the creation and development process, the Audaces360 multi-solution is recommended, as it provides precise solutions for fashion professionals.

In addition to assisting in the creation of 3D clothing, Audaces360 enables the development of high-quality and extremely precise patterns and fittings with impressive fabric efficiency.

Discover more about the Audaces360 multi-solution below!

Audaces Idea

This software allows you to draw with specific resources or create directly on a 3D mannequin. This way, you can quickly bring your creations to life with a 3D printer.

Audaces Fashion Studio

This tool is used in the initial phase, namely in the creative process.

Audaces Fashion Studio is responsible for model approval for subsequent production stages, creating technical sheets, developing patterns, and making a pilot piece.

It also simulates garments in a 3D environment.

Audaces Pattern

Another vital solution for the creation phase, Audaces Pattern dynamically develops high-quality and extremely precise patterns.

This software also scans and extracts the pre-modeling done in Audaces Fashion Studio.

Audaces Marker

Designed to increase profitability by optimizing the use of raw materials, Audaces Marker is a game-changer in the garment production.

It also generates cutting order reports and calculates fabric consumption by color, streamlining the material separation process for cutting.

It includes tools for cutting details, line suppression, and digital print configuration.

Audaces Supera

Audaces Supera is a queue processing management tool for markers sent by one or more computers throughout the company. This precise control increases fabric utilization, saves time in processes, and boosts overall business productivity.

Audaces Isa

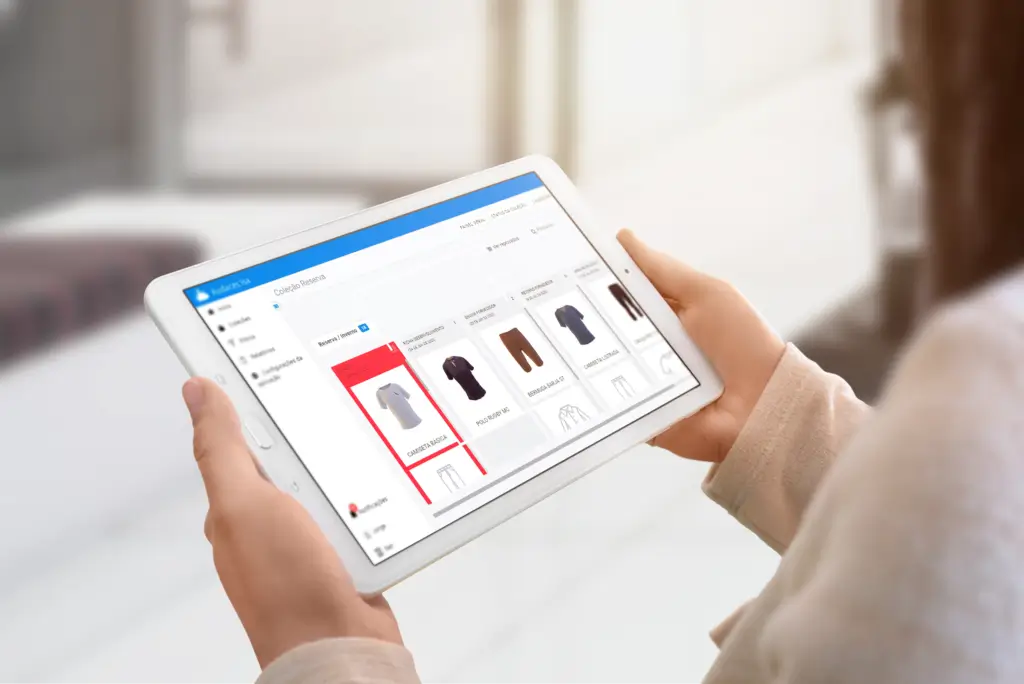

Audaces Isa is a platform that enables the management of each of your collections, step by step, through production.

This convenience connects the entire company and allows your design teams to focus on the development process, achieving greater accuracy and increasing brand profits.

Conclusion

Planning and controlling production are complex processes that involve various stages, but ultimately ensure more efficient, accurate, and profitable production.

To develop this efficiently, it’s essential to work with intelligent tools tailored to each specific situation.

Working with Audaces360 guarantees you have a complete multi-solution for the planning and control of all your resources and processes, covering all stages and aspects of the production chain.

Did you find this content useful? Follow the Audaces blog to stay updated on the latest content.

Below, we offer thi super valuable e-book containing additional important information to assist you – and the best part? It’s free!

FAQ

It stands for Production Planning and Control, a set of tools used to coordinate production operations in industries.

Demand forecasting, determining production capacity, aggregate production planning, master production schedule, detailed production scheduling, and production control.

It reduces costs, speeds up production and operational accuracy, provides metrics and indices, and optimizes management processes overall.