Summary:

- Rotary printing employs etched metallic cylinders with engravings to apply ink onto fabrics;

- The process supports up to eight colors for the image to be printed;

- Create your collection seamlessly with Audaces Fashion Studio, a solution that offers a practical approach to 3D design. Get the free trial of Audaces360 multi-solution today!

There are various fabric printing techniques available, but today we will focus on rotary printing.

This method plays a significant role in people’s day-to-day lives, from clothing to accessories and even home decor items.

With rotary stamping, the entire fabric surface is filled with the design, resulting in more precise and accurate pattern sequences.

While it may be a little more expensive, the cost per unit decreases with higher production quantities.

Curious to learn more about rotary printing? Then join us and keep reading!

Sumário

What is rotary printing?

Rotary printing utilizes large metallic cylinders engraved with the desired garment image.

This technique uses a variety of colors and contrasts to print designs, making it the industry leader in textile printing.

In addition to its output, rotary significantly helped the industrial revolution by facilitating high-quality fabric printing at scale.

As said before, while this printing method is typically more expensive, it becomes more affordable for larger fabric quantities.

So, the investment might be worth it! Rotary printing is the ideal choice for those looking to produce medium to large quantities of printed fabrics.

How does rotary printing work?

Production with rotary prints works as follows: the cylinders are engraved and perforated with the images to be printed onto the fabric surface.

This method results in an all-over pattern, as the design is engraved onto the entire cylinder surface.

Rotary printing enables the creation of unique effects that cannot be achieved with other printing methods, providing a wide range of print options for fabrics.

Learn more about these techniques below!

What types of prints are produced by rotary printing?

Rotary printing offers a range of print options, which require technical skills and attention to detail to produce successfully.

Let’s explore the four primary types:

Frame printing

Frame printing is one of the most common rotary printing techniques, utilizing nylon screens with various perforations.

This method allows for up to eight colors to be used, with each frame corresponding to a single color.

It also can be done using both manual and digital processes. The digital process engraves the design onto the screen, while the manual process uses photolithographs.

Cylinder printing

Cylinder printing is a technique that is similar to painting, but instead of passing through screens, the fabric passes through metallic cylinders.

These cylinders are engraved using either laser or photolithography.

This technique is commonly used for high-end textiles, as it allows for greater detail and color accuracy.

All-over printing

This process involves printing a design over the entire surface of the fabric without any gaps or white space.

It is commonly referred to as allover printing and is often used for large-scale prints or patterns.

It is often a cost-effective option for small and medium-sized garments.

However, because the design is printed over the entire surface, it may require additional care during the cutting and sewing process to ensure that the design matches up seamlessly.

Sublimation print

This is a technique that involves transferring a print from offset paper to fabric using a heat press. When heat is applied to the paper, the ink is released and binds to the fabric fibers, creating a vibrant and long-lasting print.

While this technique can be used on a wide variety of fabrics, it is important to note that it is most effective on fabrics that are at least 50% polyester. Additionally, sublimation printing allows for a greater range of colors and designs, including the use of photographs.

Learn more: Discover the best types of fabric for sublimation printing

Rotary vs digital printing: what’s the difference?

Digital printing and rotary printing are two different methods for creating fabric designs, each with its own characteristics.

While digital printing does not require the use of cylinders like rotary printing, it is typically more expensive due to the price of ink and machinery – which can cost up to three times more than other types of printing.

Despite its higher cost, digital printing offers some benefits over the rotary technique. For instance, digital printing is an eco-friendlier option, as it generates less pollution during the printing process.

Additionally, digital printing is a great choice for small production runs, as it allows for greater design flexibility and faster turnaround times.

However, it is important to note that not all fabrics are suitable for digital printing. Some fibers do not have good ink fixation and may not produce the desired results.

Therefore, it is important to carefully select the fabric and printing method to ensure the best possible outcome.

Learn more: What textile processing is and how it adds value to your production

Pros and cons of rotary printing

As with any printing method, rotary printing has its advantages and disadvantages.

By understanding these factors, you can better assess whether it is the right choice for your needs.

Below are some of the pros and cons of rotary printing that you should consider:

Benefits

Rotary printing can make garment production easier, faster, and of better quality. One of the primary benefits is the use of pre-selected images on cylinders, which streamlines the printing process and guarantees consistent results.

Here are some additional advantages:

Efficient production of large volumes

Rotary printing is particularly well-suited for printing fabrics in large quantities. It is an efficient process that can save time and money, making it an ideal choice for high-volume garment production.

Customizable design variations

With rotary printing, it is possible to create variations on the foundation of the cylinder for the same design. This allows for greater customization and flexibility in the printing process. Additionally, up to eight colors can be used in a single print, providing greater design options for garment producers.

Disadvantages

While rotary printing has its benefits, there are also some downsides to observe. Firstly, it can be one of the most expensive printing techniques, demanding a significant investment to produce.

Additionally, the process can be more polluting to the environment, resulting in other expenses. Furthermore, there is a limitation on the number of colors that can be used in rotary printing.

See the details below:

Higher investment for small businesses

Rotary printing can be expensive for small clothing companies as the cost per piece increases for smaller production runs.

Due to the need for pre-made cylinders, underused cylinders can become a significant expense. As a result, other printing methods may be more suitable for smaller businesses.

Learn more: Get to know the top 6 textile printing types and their applications

Higher environmental impact

Rotary printing can have significant water, chemical, and energy use.

The process requires a separate screen for each color in the design, contributing to the increased use of resources. This makes it less sustainable compared to other printing methods.

Learn more: Learn what ESG score is and how to apply it to your clothing company

Which types of fabric are suitable for rotary printing?

Rotary printing is a highly versatile technique that can be applied to a variety of fabrics and segments, including:

- Casual wear;

- Lingerie;

- Fitness wear;

- Children’s wear;

- Sleepwear;

- Bedding;

- Swimwear;

- Curtains;

- Home decor pieces in general.

This method offers a great deal of flexibility in terms of fabric selection, making it an ideal choice for many industries and applications.

Achieve high-precision prints with Audaces digital solutions

With the cutting-edge technology offered by Audaces machines and systems, you can achieve greater precision and efficiency in your production process.

Audaces solutions allow you to prepare and simulate your prints digitally, ensuring that your final product meets your exact specifications.

Find out how next!

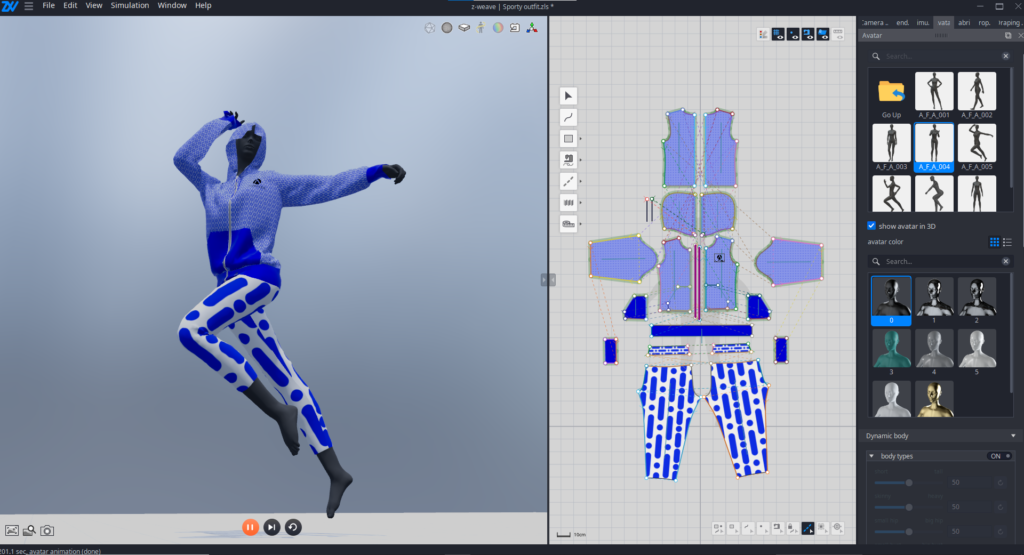

Audaces Fashion Studio

Audaces Fashion Studio is a software program that empowers stylists, designers, and pattern makers to design their pieces in a 3D environment, saving time and integrating the creation and production stages seamlessly.

Using this system, you can:

- Create three-dimensional designs without the need for developing patterns;

- Visualize your fabrics, colors, and finishes on each model;

- Present 3D designs to clients for visual approval;

- Minimize time, money, and material waste;

- Approve model variations;

- Real-time integration with pattern editors.

Audaces Pattern

This is a powerful tool for those seeking to optimize their time and streamline the printing process.

As a part of the Audaces360 multi-solution, Audaces Pattern is fully compatible with rotary printing and simplifies the creation of patterns with both localized and continuous prints.

This technology is fast, efficient, and profitable. With Audaces Pattern, you can easily manage prints and patterns, saving time and increasing efficiency in the process.

Audaces Jet Lux

Discover the Audaces Jet Lux plotter, the ultimate solution for pattern printing. This state-of-the-art plotter is not only faster than other plotters on the market but also produces precise and flawless lines.

The Jet Lux is perfect for those who aim for excellence in their processes and wish to save time and resources, in addition to having:

- Specialized technical assistance;

- Silent operation;

- Cost-effective print cartridges;

- Automatic voltage system;

- Sensors for paper and cartridge levels;

- Low maintenance cost.

Conclusion

In conclusion, rotary printing is a printing method that can be applied to various types of fabrics, making it a suitable option for many fashion segments.

With the use of pre-selected image cylinders, it enables faster and easier production with improved quality in the industry.

If you want to learn more about how to create and simulate incredible prints in 3D, we invite you to download our free e-book now!

FAQ

Rotary printing is a technique that uses large metallic cylinders with engraved images to make printings garments and fabrics.

The cylinders used in rotary printing are engraved and perforated with images that will be used for printing. The fabric is then passed through the cylinders, and the chosen image is transferred to the entire fabric.

While the rotary technique uses cylinders for printing, digital printing does not. Digital printing is a good option for small productions, as it offers greater flexibility and the ability to print smaller quantities without the need for engraving cylinders.

2 Responses

What is the max height artwork can be for rotary printing?

It’s the height or the print that’s a concern right? The width of the print doesn’t matter?

Hi, Liz!

Yes, the height is the main concern as it depends on the cylinder’s circumference, which varies by supplier. The width isn’t limited since the fabric moves continuously through the printer.

Thanks for following the blog!