Summary

- Textiles are the heart of furniture design. They have the power to make or break a piece.

- With an advanced furniture cutting machine, you can create products faster and more precisely.

- Audaces360 offers all the solutions you need to streamline your textile production. Try it free for 15 days!

Choosing the right furniture cutting machine is an important decision for anyone in this industry. The right machine can make your work easier, faster, and more precise.

With so many options available, it can be hard to know where to start. But knowing your needs is the first step to making an informed decision.

Let’s explore each type in detail and its main benefits. By the end, you will have a solid understanding of your options to make the best choice.

Happy reading!

Sumário

Why invest in a good furniture cutting machine?

A high-quality machine offers precise cuts, which leads to better-fitting parts and smoother finishes.

This is especially important when working on furniture, where small mistakes can affect the final product. With a reliable cutting machine, you can achieve consistent results every time.

Good machinery also saves you time. It can cut through materials faster and more efficiently, allowing you to complete projects in less time.

This means you can take on more jobs or focus on other aspects of furniture making, like assembly or finishing. In the long run, a faster cutting process will help increase your productivity.

Another key reason to invest in a quality machine is durability. Good furniture cutting machines last a long time and handle heavy use without frequent breakdowns.

It reduces the need for repairs or replacements, saving you money and avoiding disruptions in your workflow. A solid investment in the right equipment can pay off over time.

Learn more: How to obtain quality and precision in the cutting fabric process?

Main types of furniture cutting machines

There are different types of cutter machines, each suited for specific tasks. Choosing the right one depends on the material, precision needed, and the scale of your production.

Flatbed cutting machine

The flatbed cutting machine is perfect for cutting fabric or soft materials. It uses a large, flat surface to place the material and the cutting tool moves across it.

These machines are common in industries like upholstery, where large sheets of fabric turn into smaller pieces.

One of the main advantages of flatbed cutting machines is their ability to handle large volumes of material.

They can cut complex shapes and patterns with great precision, reducing material waste. It makes them an excellent option for mass production, where high throughput and consistency are key.

With advanced software, they can automate the cutting process, saving time and labor. It’s a top choice for businesses looking to scale their operations.

Learn more: 7 key factors to look for in the best fabric cutting systems

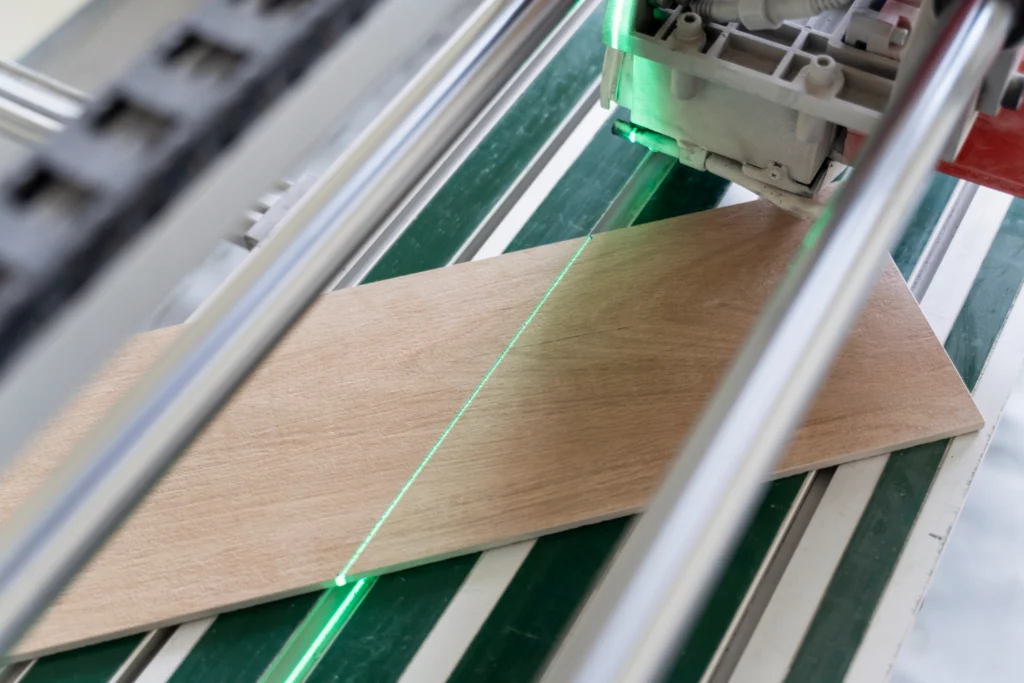

Laser cutting machine

This kind of machinery uses a laser beam to cut through fabric and other materials. It provides very precise cuts and can create intricate patterns and designs with ease.

The laser melts the material, leaving a smooth edge without the need for extra finishing.

One of the main benefits of laser cutting is its precision. The laser beam can cut through multiple layers of fabric without damaging the material. It’s perfect for detailed patterns or delicate fabrics.

Another advantage is that the process is clean and produces minimal waste. Since the laser heats the material, it also seals the edges, reducing fraying and the need for additional work.

Waterjet cutting machine

The waterjet cutting machine uses high-pressure water, sometimes mixed with abrasives, to cut through materials.

This method is clean and precise, allowing for intricate designs without fraying or burning. It’s a versatile cutting technique that can handle various materials beyond textiles.

They are particularly useful for cutting materials like certain types of fabric or foam, which heat may damage. The water jet doesn’t produce heat, so it avoids altering the material’s properties.

However, waterjet cutting machines can be slower compared to other methods, especially for large-scale cutting.

Learn more: Learn why regular maintenance is crucial for fabric cutting machines

Circular saw cutting machine

This method uses a rotating blade to cut through fabric or other materials. It works for thicker fabrics or materials that require a straight cut.

Circular saws are typically more affordable compared to advanced cutting machines like lasers or waterjets.

They are also easy to operate and maintain. These machines can cut through a wide range of materials, including thick upholstery fabrics or layered textiles.

It makes them a popular choice for basic furniture production where high precision is not as critical.

One disadvantage of using a circular saw is that it may leave rough edges on some materials. This could require additional finishing work, such as trimming or sealing the edges.

However, it is still an efficient choice for straightforward cutting tasks. They are ideal for businesses on a budget that need a reliable and simple cutting method for basic materials.

Learn more: Learn how to use types of nautical fabric in your upholstery production

How to assemble a furniture cutting machine?

Assembling a furniture cutting machine requires careful attention to detail and following the manufacturer’s instructions.

The first step is to ensure that you have all the parts and tools needed for the assembly. This may include the machine’s frame, cutting components, motors, electrical wiring, and safety features.

It’s also important to have a spacious area to work in, so you have room to move the parts and assemble them.

Start by assembling the main frame of the machine. Secure it using the bolts and screws provided. Make sure all connections are tight and aligned to ensure stability during operation.

Run a test cut on scrap material to ensure everything is working smoothly. Check the machine for any unusual sounds or vibrations.

To save you time and effort, some companies provide assembly and installation services.

If you want to receive a free personalized project on how to automate your cutting room, simply fill in your email address below!

Benefits of investing in a good furniture cutting machine

Investing in a high-quality furniture cutting machine can bring several advantages. These benefits can help improve efficiency, reduce costs, and enhance the quality of your work.

Increased productivity

A good furniture cutting machine can boost productivity. It can cut materials faster and more efficiently than manual methods.

It means you can complete more work in less time, allowing you to take on more projects.

With automation features, many cutting machines can work non-stop, reducing the need for constant supervision. It’s particularly useful for large-scale operations where time is of the essence.

The machine’s ability to handle multiple materials and cuts at once also speeds up the process.

Learn more: Discover how to choose the perfect furniture design software

Material savings

Efficient hardware helps you save on materials. Precision cutting reduces waste by ensuring that every cut is as accurate as possible.

This is especially important when working with expensive materials, such as high-quality fabrics.

By reducing waste, you can also reduce the cost of materials over time. It’s an advantage for businesses that work with large volumes of raw materials.

With fewer off-cuts and scraps, your material costs can decrease, leading to higher profit margins.

Cutting precision

Cutting precision is one of the main reasons to invest in a good machine. Accurate cuts are essential for creating well-fitting parts and achieving a smooth finish.

With a high-quality cutting machine, you can expect sharp edges that require little to no additional finishing.

Precision is especially important when working with intricate designs or complex shapes. A good cutting machine ensures that every cut is exactly where it needs to be.

In addition, better precision helps maintain the quality of the final product. This is paramount for industries where quality and consistency are key to customer satisfaction.

Learn more: How can a good cutting plan transform your production?

Easy operation

Another benefit of investing in a good furniture cutting machine is easy operation. Modern machines come with user-friendly interfaces, making them simple to operate.

Many machines have touchscreen controls, clear instructions, and preset options that make setup quick and easy.

Automated functions reduce the need for constant adjustments. Once you input the settings, the machine can run on its own, cutting materials with minimal intervention.

This ease of use reduces training time for employees and helps them get up to speed faster.

The streamlined operation also minimizes the risk of operator error. The machines perform most of the work automatically, reducing the chance of mistakes.

Where to buy a furniture cutting machine?

One of the most common options is purchasing directly from the manufacturer. Many well-known brands sell their machines online or through authorized distributors.

Buying directly from the manufacturer can give you some benefits. They often include customer support, warranty options, and product recommendations based on your specific needs.

Trade shows and industry exhibitions can be great places to see cutting machines in action. These events feature the latest models, and you can meet with suppliers directly.

Attending a trade show allows you to ask questions, compare machines side-by-side, and sometimes even get special deals.

Elevate your furniture cutting with Audaces Cutting Room

By embracing cutting-edge technology, furniture manufacturers can achieve significant improvements in the production process. From greater design flexibility to enhanced efficiency and reduced costs.

This is where Audaces Cutting Room steps in! Our experts will thoroughly assess your company’s needs and create a comprehensive report.

Then, our team will develop a personalized project to achieve your goals and your company’s full potential.

Rely on Audaces’ machinery to automate your production process. Achieve impeccable cuts on curves and details, speeding up your deliveries and minimizing fabric waste through automation.

FAQ

A high-quality machine offers precise cuts, which leads to better-fitting parts and smoother finishes. This is especially important when working on furniture, where small mistakes can affect the final product.

The main types of furniture cutting machines are flatbed cutting, laser cutting, waterjet cutting, and circular saw cutting.

The benefits of investing in a good furniture cutting machine are increased productivity, material savings, cutting precision, and easy operation.