Summary

- A digital tailor excels at capturing precise measurements on a digital model.

- The tailor’s adjustments are pivotal for both the comfort and aesthetics of the produced garments.

- Discover how you can manage every phase of your collection with Audaces360’s multi-solution! Sign up for the free trial now.

The notion of a digital tailor is reshaping the landscape of custom-made clothing with the aid of technology.

By obtaining meticulous measurements, a digital representation of the customer’s body is created, ensuring that garments conform perfectly to their unique physique.

This level of precision is not only crucial for aesthetics but also for comfort, self-assurance, and the way one is perceived by others.

In the following sections, explore what a digital tailor is and the compelling reasons for incorporating one into your apparel manufacturing process, as well as the manifold benefits it offers.

Sumário

Enjoy your reading!

What is a digital tailor?

A digital tailor is a professional who harnesses technology, including 3D digitization and data analysis, to craft custom clothing with enhanced efficiency and precision.

This innovative concept entails the meticulous capture of an individual’s body measurements through specialized scanning or camera technology.

These measurements are subsequently processed by software to create a digital model of the customer’s body, enabling the creation of garments that flawlessly conform to their unique dimensions and shapes.

Learn more: 6 types of pattern-making courses to enhance your skills in the fashion industry

What’s the importance of precise clothing adjustments?

Ensuring that your clothing fits perfectly and feeling good about it represent numerous advantages that extend beyond aesthetics.

These benefits encompass comfort, self-confidence, and the perceptions and interactions of others.

Wearing well-fitted clothes is fundamentally about comfort. Apparel that is too tight or too loose can lead to discomfort, skin irritation, and restricted mobility.

When garments fit properly, they positively enhance an individual’s appearance. Excessively loose clothes can create a disheveled look, while overly tight attire may not be aesthetically pleasing.

Moreover, wearing well-fitted clothing can significantly boost self-confidence.

When one feels good about what they are wearing, it manifests in their posture and attitude. Additionally, clothing that doesn’t fit well may wear out prematurely, leading to tears or fabric deformations due to uneven stress.

Ill-fitting clothing can even impede proper blood circulation and breathing, potentially resulting in negative long-term health consequences.

Learn more: Learn what 3D modeling is and its benefits for clothing design and production

Benefits of having a digital tailor in your clothing business

Integrating a digital tailor into your clothing business offers a range of benefits, from cost reduction and waste minimization to enhanced production efficiency and the opportunity to leverage technology as a competitive edge.

These advantages can lead to a more streamlined operation, improved product quality, and a stronger market position.

Learn more about these benefits:

Cost and waste reduction

Computer-controlled cutting technology facilitates the efficient utilization of fabric, minimizing waste and reducing expenses related to excess material procurement.

The precision in collecting measurements and the use of digital patterns ensure that each garment is crafted to precise dimensions, avoiding errors that might lead to incorrect pieces and wastage of materials.

Automation of the cutting and sewing processes under the control of a digital tailor further reduces the potential for human errors, resulting in less rework, saved time, and reduced material waste.

Learn more: Discover how to reduce costs in wholesale clothing production

Agility and production efficiency

Having a digital tailor automates numerous manual processes, expediting production and allowing for the completion of more pieces within a shorter timeframe.

The technology enables swift adaptation of patterns to various sizes and styles, particularly beneficial for on-demand production, saving time and enabling a more rapid response to customer demands.

Automation establishes a smoother and continuous workflow, minimizing bottlenecks and delays that may arise with manual methods.

Leveraging technology as a differentiator

A digital tailor empowers you to explore innovative designs and styles that can stand out in the market, attracting the attention of consumers seeking exclusivity and modernity.

Furthermore, the potential for on-demand fashion customization, coupled with the swiftness of technology, enhances the customer experience, potentially leading to a loyal and satisfied customer base.

Digital technology allows you to adapt more quickly to shifting fashion trends while maintaining competitiveness in the market.

Learn more: Enhance productivity in sectors of the textile industry with technology

What’s the impact of technology on the digital tailor’s craft?

Technology is instrumental in enhancing the work of a digital tailor, revolutionizing the traditional process of creating bespoke clothing to deliver efficiency, precision, and personalization.

Explore the ways in which technology drives the work of a digital tailor:

Precision measurement collection

Digital measuring devices enable the precise gathering of customer measurements, resulting in more accurate patterns and garments that fit flawlessly.

3D modeling

Utilizing 3D modeling, a digital tailor can create precise digital representations of clothing before physical production.

This capability aids in visualizing how the garments will appear on the wearer and permits virtual adjustments before cutting and sewing.

Automated cutting

Computer-controlled cutting machines used by a digital tailor follow digital patterns with exceptional accuracy, reducing fabric waste and expediting the cutting process.

On-demand personalization

Technology facilitates the effortless modification of cutting patterns to align with individual customer preferences, simplifying the production of custom clothing on demand.

Production agility

Automation of various stages in the manufacturing process, including cutting and sewing, heightens production speed and enables swift responses to evolving market trends.

Order tracking and management

Utilizing management software enhances the ability to efficiently track orders, production schedules, and inventory, thereby minimizing delays and communication issues.

Sustainability

A digital tailor optimizes cutting patterns and maximizing fabric efficiency can significantly contribute to a more sustainable production process, effectively reducing waste and lessening the environmental impact.

Learn more: Why consider sustainable consumption and production for your company?

Achieve precision fit with Audaces

Enhancing production efficiency is paramount for a company’s success in the textile industry, and technology is a key driver of this transformation.

Explore the innovations and products provided by Audaces, tailored to streamline processes and optimize time utilization, ultimately leading to advancements in production excellence.

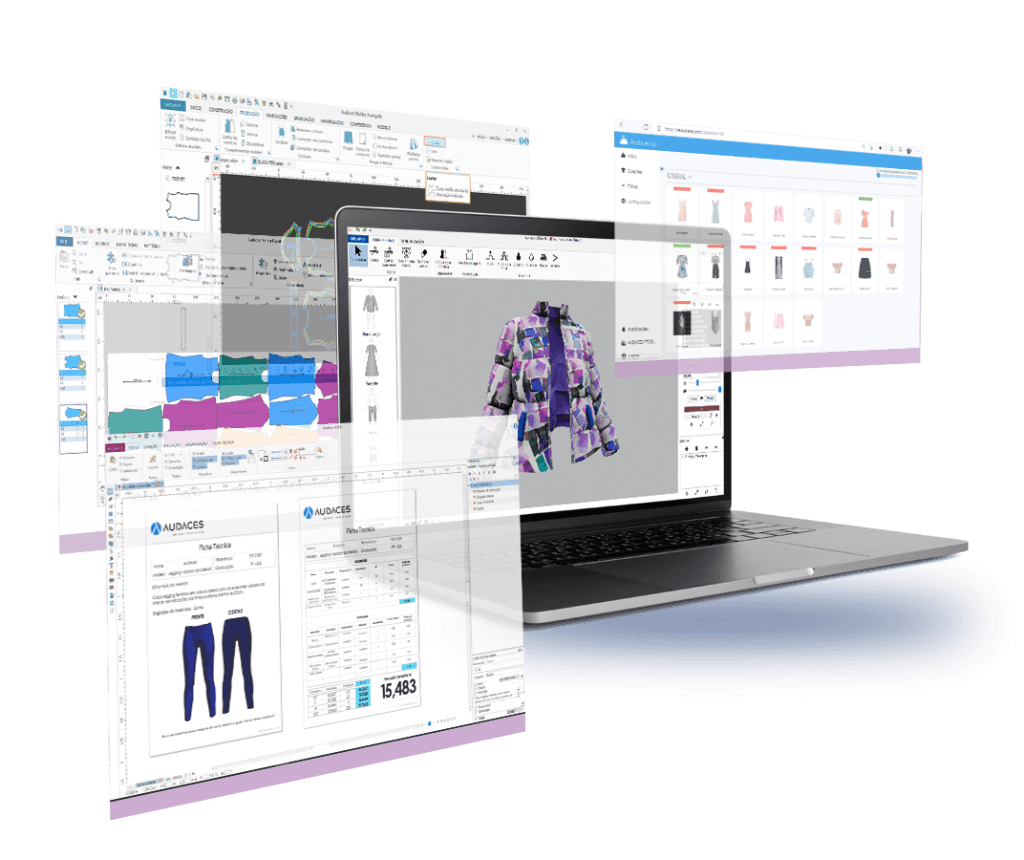

Audaces360

Audaces360 is a versatile platform that bridges the gap between the creative and productive phases, resulting in heightened precision and profitability for your clothing business.

This comprehensive system offers a holistic view of the entire production cycle, working seamlessly with complementary tools to ensure each stage synergistically contributes to the next.

Backed by reliable real-time data, Audaces360 streamlines decision-making, making it agile and effective.

Its diverse capabilities accelerate the manufacturing process, while also facilitating order customization, ultimately enhancing operational efficiency.

Audaces Pattern

Audaces Pattern stands out as an invaluable ally for those seeking to expedite the collection production process, featuring an intuitive and user-friendly interface.

This efficient high-speed technology enables the rapid creation of digital patterns, surpassing manual methods by approximately 70%.

Moreover, this solution integrates an automatic measurement table, simplifying pattern development, even for the most intricate designs, and expediting the grading process, thereby reducing paper usage.

Audaces 3D

Audaces 3D simplifies the creation of three-dimensional models on virtual mannequins, offering a suite of powerful tools.

With this solution, the need for physical pattern molds is eliminated, resulting in resource and time savings. You can expedite deliveries and position yourself as a fashion professional leveraging Industry 4.0 technology.

Our software enables you to assess the fit and wearability of garments by simulating the appearance on avatars, eliminating the need for costly physical prototypes.

This digital approach not only reduces costs but also contributes to sustainability by minimizing paper and physical material consumption, thus reducing environmental impact.

Discover more insights on how to transform your clothing business by downloading our free e-book:

FAQ

A digital tailor is a professional who leverages technology, including 3D scanning and data analysis, to craft customized clothing with greater efficiency and precision.

Perfect clothing adjustments are essential for comfort, self-confidence, overall health, and how one is perceived by others.

Technology revolutionizes the traditional process of creating custom clothing, enabling a more efficient, precise, and personalized approach.