Summary

- Precision cutting is the key to a seamless manufacturing process and high-quality garments.

- For optimal efficiency in medium to large-scale production, fabric cutting systems are paramount.

- Experience the power of Audaces360 to manage your entire process. Try it for free now!

After spreading and marking, cutting is the cornerstone of apparel production. It directly impacts how efficiently you can produce garments, meet deadlines, and maintain high quality.

To scale or modernize your business, investing in fabric cutting systems can be a strategic move. These systems offer numerous benefits and can give you a competitive edge.

However, choosing the right cutting system can be challenging. So, let us guide you through the process! Discover how optimized cutting can transform your business.

Enjoy your reading!

Sumário

What is the role of fabric cutting systems in garment manufacturing?

Tools like straight knives and rotary cutters can be enough for small productions. However, medium to large-scale companies must rely on fabric cutting systems to optimize results.

In automated cutting processes, specialized software solutions bridge the gap between people and equipment. They act as an interface, making it easier for operators to control and monitor the cutting machines.

Fabric cutting systems are vital for maximizing your return on technology investment. By streamlining workflows and ensuring precise control, they empower you to optimize production efficiency and minimize waste.

With cutting systems in place, you can effectively manage your cutting room and guarantee that operations run smoothly.

These systems are particularly critical for businesses handling diverse fabric types. Their advanced capabilities guarantee consistently perfect cuts, regardless of the material.

Learn more: 6 benefits of automatic cutting for your fashion business

Essential features of a high-performance fabric cutting system

Investing in fabric cutting systems requires careful consideration. Therefore, explore and compare various solutions.

Evaluate these factors to ensure they align with your company’s specific requirements:

1) System precision and speed

For optimal garment production, fabric cutting systems must excel in both precision and speed. High accuracy ensures that every cut aligns perfectly with design specifications, reducing material waste and ensuring a flawless fit.

At the same time, rapid cutting capabilities ensure your business meets deadlines and enhances throughput.

Modern technologies integrate seamlessly to provide both swift and precise results, enabling your company to reach its full potential.

Learn more: How to overcome slow cutting in your apparel manufacturing?

2) Planning and cutting order

Effective management of cutting plans and orders maximizes fabric usage and simplifies the workflow.

Sophisticated systems incorporate advanced planning software that optimizes organization, ensuring you get the most out of raw materials and reducing unnecessary waste.

Automation in planning and cutting orders facilitates a smoother production process, avoiding delays and improving operations.

Learn more: 4 textile technologies that are reshaping fashion

3) Management of different cuts and spreads

Versatile fabric cutting systems adeptly handle various types of cuts and fabric spreads. By adjusting settings for different materials and patterns, it is possible to maintain consistent quality across all designs.

Effective systems provide flexible options and precise adjustments. You can manage details such as the number of layers and the amount of fabric.

The capability of adapting machinery to a range of fabric types ensures reliable performance for all production needs.

Learn more: 5 strategies to optimize your production with efficient fashion

4) Efficient waste management

Effective waste management is a key component of a cutting system’s efficiency. Through intelligent algorithms and cutting innovation, these systems minimize fabric waste and enhance material usage.

By optimizing marking and cutting, manufacturers can reduce excess material and lower production costs, contributing to more sustainable practices and improved profits.

Learn more: 4 reasons you should invest in a cutter room for fashion

5) Fabric defect alerts

Fabric defect detection will greatly simplify your process and enable you to achieve higher quality levels.

Automated machines have sensors that identify defects like holes and tears during the cutting process. The fabric cutting system will notify you of the error, and you can select the appropriate corrective action.

This approach helps you to use only high-quality fabric and reduces the risk of producing imperfect products.

Learn more: Why should your company invest in fabrication technology?

6) Maintenance and technical support

Ongoing maintenance and robust technical support are essential for sustaining system performance and longevity. Comprehensive service offerings include routine maintenance, troubleshooting, and prompt repairs.

Access to expert support guarantees a quick resolution of any technical issues. This helps minimize downtime and maintain smooth production operations.

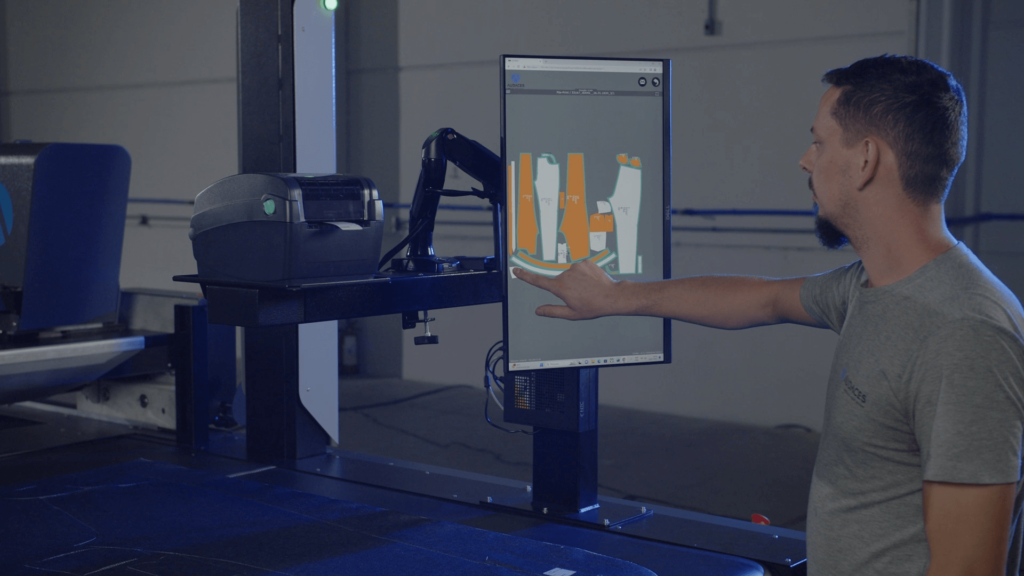

7) Ease of use and operator ergonomics

One of the primary factors to consider when selecting fabric cutting systems is the ease of use. A user-friendly interface with clearly visible tools and intuitive features is essential.

This ensures operators feel comfortable using the system, reducing the need for extensive training.

Implementing such a system also improves ergonomics for workers. Instead of spending hours standing at the cutting table, operators can now work comfortably on the system. It helps to enhance their well-being and quality of life at work.

Have you fully grasped the benefits that fabric cutting systems can bring to your garment manufacturing?

If you’re looking to automate your entire process but aren’t sure how to begin, rest assured, we have the solution. Audaces’ automated cutting room is designed to deliver a personalized project tailored to your specific needs.

Our team of experts will conduct a thorough evaluation of your company and provide a comprehensive report.

It will delve into the specifics of your production and identify the optimal technology to streamline your processes.

By partnering with Audaces, you’re making a sound investment with a guaranteed rapid and efficient return.

To schedule a consultation with one of our specialists, simply fill in the field below!

Benefits of investing in fabric cutting systems for your business

So, you’ve got a good grasp of what to look for. But still unsure about investing in fabric cutting systems?

Let’s dive into some of the benefits they can bring to your garment manufacturing.

Increased production capacity

Investing in advanced fabric cutting systems significantly boosts your production capacity. These systems streamline the cutting process, allowing for faster and more efficient handling of large volumes of fabric.

And if it’s part of a complete system that covers the entire development and production process, that’s even better!

By automating repetitive tasks and optimizing workflows, these solutions enable your business to increase output. Besides, you can meet higher demand without compromising quality, offering a compelling value proposition to clients.

Learn more: Enhance productivity in sectors of the textile industry with technology

Reduced waste

Fabric cutting systems contribute to substantial waste reduction. Through advanced marking intelligence and precise cutting technology, these systems maximize fabric usage and minimize excess material.

Efficient waste management not only lowers production costs but also supports more sustainable manufacturing practices, helping your business to reduce its environmental footprint.

Learn more: Learn more about fabric yield and avoid waste in your production

Precise cuts

High-performance software and hardware ensure exceptional precision in every cut. This accuracy guarantees the integrity of garment designs and ensures that pattern pieces fit together perfectly.

By delivering consistent perfect cuts, these systems help in producing high-quality garments with fewer defects and reworks.

Achieving this level of efficiency will enhance your product’s value, opening doors to new markets and boosting your profits.

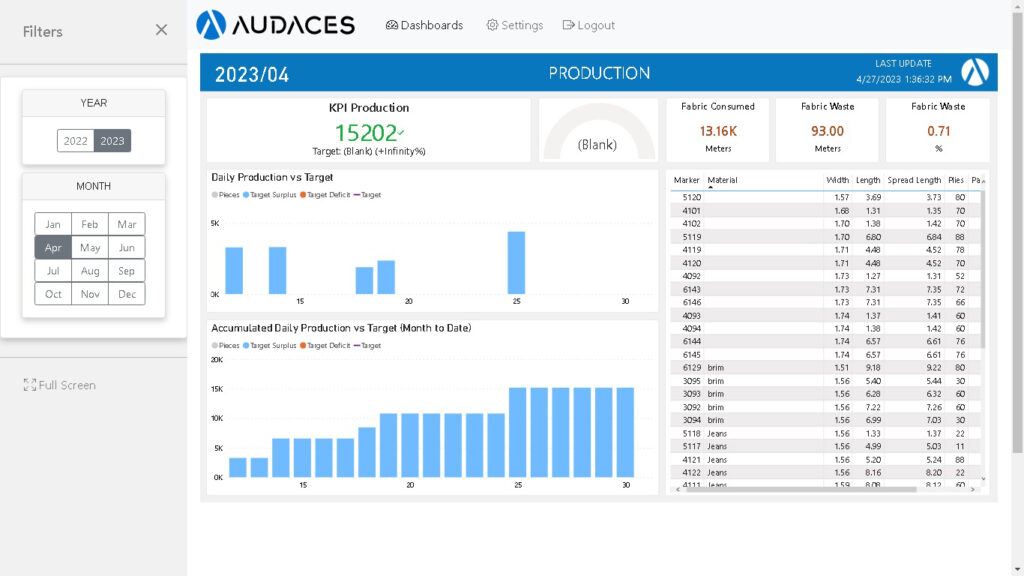

Real-time production management

This is the benefit that can be a real game-changer for your business! No more discovering cutting errors at the end of the process, when it’s often too late to fix them.

By providing immediate feedback on the cutting process, real-time tracking allows you to proactively identify and resolve issues. It prevents costly errors and reduces fabric waste.

This data-driven approach allows you to make informed decisions and improve overall efficiency while meeting production schedules.

What is the best fabric cutting system on the market?

Determining the best fabric cutting system on the market depends on some elements specific to your business needs.

In addition to the factors we’ve listed, also consider the system provider’s expertise and focus on the textile industry.

Audaces, a company with over 30 years of experience in fashion solutions, has developed the most comprehensive fabric cutting system. Meet Audaces ICF!

Boost your apparel production with Audaces ICF

Audaces ICF is an intelligent technology that seamlessly connects people, hardware, and fabric cutting systems.

Fully digital and focused on data security, it offers the best tools for precise planning and management of spreading and cutting processes.

In addition to streamlining your workflow, the online platform ensures access for all stakeholders. All information is available in real time via smartphone.

Managers can effortlessly schedule cut orders, specifying details like spreads, layers, cuts, and fabric quantities.

The system proactively identifies potential errors to enhance your company’s efficiency. monitors progress and alerts you to any discrepancies between planned and completed tasks. It also provides suggestions for resolving these issues.

Was this article helpful? Receive our content first hand by subscribing to the Audaces newsletter!

FAQ

Tools like straight knives and rotary cutters can be enough for small productions. However, medium to large-scale companies must rely on fabric cutting systems to optimize results.

System precision and speed, planning and cutting order, management of different cuts and spreads, efficient waste management, fabric defect alerts, maintenance and technical support, and ease of use and operator ergonomics.

Increased production capacity, reduced waste, precise cuts, and real-time production management.