Summary

- Enhanced productivity, quality, and standardization are some advantages of digitizing clothing patterns

- This form of pattern bestows agility and precision upon the work conducted by the pattern-maker

- By utilizing Audaces360, fashion professionals can craft patterns with unparalleled precision, quality, and efficiency. Experience the benefits with a free trial today!

Mastering the digitalization of clothing patterns sets fashion professionals apart in their field.

Transitioning from a manual, labor-intensive, and time-consuming process to a CAD-based modeling system introduces heightened dynamism and precision, directly influencing production costs and quality.

Thanks to these advantages, digital modeling systems have become integral to most major players in the textile industry.

Moreover, enticed by the practicality of this resource, an increasing number of small and medium-sized companies are eager to embrace this technology.

Sumário

Within this content, you’ll delve into the mechanics of clothing pattern digitalization and explore the primary benefits of Audaces360.

This comprehensive solution spans every facet of the fashion supply chain.

Keep reading to uncover more!

Why digitize clothing patterns in your fashion production?

Empowered by proficient software, fashion professionals can craft clothing patterns with precision, quality, and efficiency.

This capability allows patternmakers to conceptualize entire collections on their computers, thereby fostering a positive influence throughout the entire production chain.

Explore the advantages of incorporating digital modeling into your fashion production below!

1. Enhanced productivity

Swift creation and adjustments become the norm. With a mere few clicks, additions like pleats, darts, or new cuts can be seamlessly incorporated.

2. Higher quality

The digitalization of clothing patterns facilitates unparalleled precision in constructing pattern blocks, ensuring parts exhibit impeccable symmetry and exact measurements.

3. Standardization

Imagine a company consistently replicating a design or a specific pattern block. When paper is utilized, wear and tear during daily handling and copying can lead to measurement discrepancies.

Through digital modeling, an unlimited number of molds can be generated, ensuring unwavering measurement consistency.

4. Clothing pattern gradation

Utilizing millimeter measurements, the system operates within the confines of the X and Y Cartesian plane, maintaining a steadfast 1cm as precisely 1cm. In manual pattern making, however, this dimension can fluctuate between 0.95 and 1.1 cm.

Consider this: even the pencil employed by the pattern maker can exert an influence on the ultimate outcome of the pattern.

Learn more: Discover the benefits of a pattern grading chart for your clothing production

5. Precise gradation assessment

Leveraging the suite of digital tools, one can swiftly verify all enlarged pattern measurements within a matter of minutes. This includes meticulous examination along the stitching line itself, transcending mere outline scrutiny.

6. Limitless digital repository

Every clothing pattern finds its home within your computer’s storage. This signifies a departure from the inefficiencies of space-consuming physical files and paperwork, thereby mitigating the risk of pattern deterioration and loss.

7. Full integration

A singular software has the capacity to integrate the entire garment, endowing it with programmability, control, and connectivity. Furthermore, information flow between interconnected sectors occurs in real-time, rendering all data effortlessly accessible.

8. Measurement chart generation

Creating measurement tables becomes effortless, achievable with just a few clicks. Additionally, you can share this critical data and more with pertinent departments.

9. Consumption calculation

Calculation and evaluation of piece fitting are easily achievable, fostering raw material conservation. Furthermore, the software can pinpoint grids and fabric widths, optimizing material utilization.

10. Reduced physical fatigue

Conducting tasks online curtails physical strain on the professionals involved.

Unlike the manual process, where hours of standing are required, digital modeling significantly minimizes the time required for fitting work—often by at least 80%, particularly with standardized practices.

11. Remote communication

For industries and independent professionals, remote communication with teams and clients is made feasible, transcending geographical limitations.

12. Sustainability

The adoption of digital clothing patterns substantially diminishes paper consumption in garment production, given that all data is archived in the cloud or locally on machines.

Moreover, the specification of sewing processes and pattern grading is streamlined.

A noteworthy benefit lies in the solution’s versatile potential for delineating pattern cuts, bestowing pattern makers with the freedom to choose lines and directions.

Demystifying clothing patterns digitization

Digitizing clothing patterns entails creating patterns online through dedicated software. This innovative approach to pattern-making imbues the work of pattern-makers with enhanced agility and precision.

The process unfolds directly on the computer, commencing with the creation of a two-dimensional model before progressing to a three-dimensional rendition.

The employed software programs expedite the production process, optimize time, and resource utilization, and elevate the precision of pattern creation.

Learn more: Find out the finest apparel manufacturing softwares for your company

How does a digital modeling system operate?

There’s no denying that CAD systems have wrought a revolution across various industrial sectors.

Within the realm of fashion, these solutions have injected heightened swiftness into modeling, rendering the creation of new collections notably more straightforward.

The operational framework of CAD systems rests upon Cartesian coordinates. This underpins the rapidity and measurement accuracy intrinsic to digital modeling, irrespective of mold intricacy. Cartesian coordinates are predicated on two axes, namely X and Y.

Here, X denotes the horizontal axis, while Y represents the vertical one. These axes are akin to a metric scale, marked with values.

The nexus of X and Y denotes the zero point, from which both positive and negative scales are delineated:

- X: Extending from zero towards the right are positive values, while negative values stretch to the left

- Y: Moving upwards from zero corresponds to positive values, whereas descending below zero encompasses negative values

These axes persist throughout the digital modeling process, serving as the bedrock for accurate gradation while adhering to actual measurements. It’s upon these coordinates that the contours of a piece are shaped.

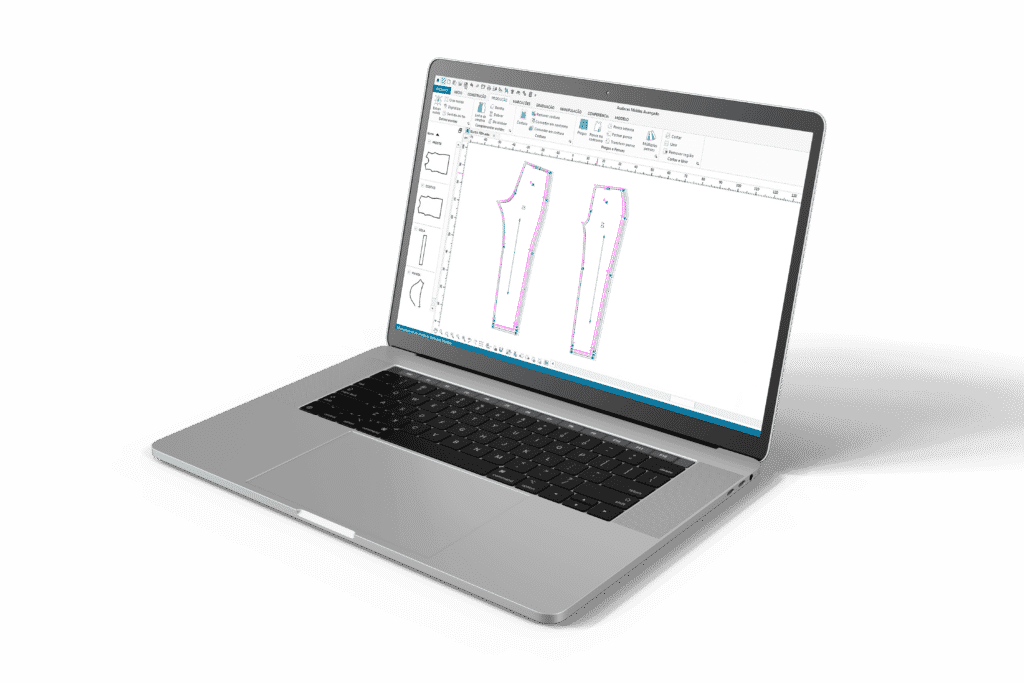

Within the realm of the Audaces360 multi-solution, Audaces Pattern emerges as a digital modeling tool. This system is orchestrated from Cartesian coordinates within the CAD framework.

Discover below how this tool has the potential to revolutionize your garment production!

Unleash the power of digital clothing patterns with Audaces360 multi-solution

The digital modeling process facilitated by Audaces360 boasts a remarkable level of intuitiveness. This is primarily due to the system’s incorporation of variants derived from a pattern block.

Consequently, an array of alterations can be effortlessly registered, obviating the necessity to repeatedly construct it from the ground up.

Given that Audaces360 significantly amplifies the efficiency and precision of pattern development, the associated costs of this phase experience a reduction.

This not only translates to savings on garment samples but also averted instances of flawed components or other elements that could impede product sales.

Find below a selection of our paramount solutions:

Audaces Digiflash

Simplicity represents the essence of Audaces Digiflash. With this tool, paper-based patterns are swiftly scanned and seamlessly transformed into digital templates within seconds.

What’s more, the original model remains fully editable, preserving your creative flexibility.

Audaces Pattern

Audaces Pattern empowers you to create intricate and precise clothing patterns of the utmost quality, all while enjoying a streamlined and uncomplicated process.

This tool enables you to construct the entire modeling phase directly from your computer, ensuring efficiency and precision in every step.

Audaces 3D

Craft your collection without unnecessary resource or time expenditure! Audaces 3D empowers you to endorse designs online, verify garment fit, and curtail time and expenses associated with garment sampling.

Discover the comprehensive process of developing your fully digital patternmaking through our free e-book:

FAQ

Digital clothing patterns are crafted online using specialized software.

Digital patternmaking utilizes Cartesian coordinates within the CAD system, enabling swift and precise pattern creation, regardless of intricacy.

Benefits include enhanced productivity, superior quality, standardization, pattern grading, grading verification, sustainability, and more.