Summary

- We already know that technology has the power to transform every process in the fashion market.

- But when we’re talking about industrial scale, do you know how CAD systems can optimize your company’s work?

- Experience the future of fashion with Audaces360. Start your free trial today!

If you own a fashion business and still rely on manual methods, you could be missing out on big opportunities. Industrial CAD technology can bring more speed, accuracy, and control to your production process.

Here’s a question for you: Do you know exactly what industrial CAD is? And why are people calling it a game-changer for fashion production? Those are the questions we’ll explore in this article.

You don’t need to be a tech expert to understand the benefits. We’ll explain everything in a simple and practical way. By the end, you’ll discover why all the big manufacturers are making the switch.

Happy reading!

Sumário

Why use industrial CAD in your apparel manufacturing?

Industrial CAD can bring big results to your fashion business. It helps you improve how you design, create, and produce clothing. Instead of doing everything by hand, you can count on smart tools to speed up your work.

This type of technology allows your team to make fewer mistakes. You can see patterns on screen, change sizes, and test different models before going into production. It saves time and reduces fabric waste.

With CAD software, you don’t need to start from zero every time. You can use existing designs, adjust details, and create new versions easily. This keeps your team focusing on what really matters: product development and innovation.

Another strong point is collaboration. Industrial CAD makes it easy to share files between team members, even if they are working from different locations. Everyone stays aligned and can move faster.

Learn more: What is CAD software and why use it to produce fashion?

What is industrial CAD?

Industrial CAD means Computer-Aided Design made for fashion and textile companies. It’s a set of digital tools used to create, adjust, and manage patterns and markers.

This system is much more than just design software: it brings precision to each step. You can create a pattern, grade sizes, and even plan the fabric cut in the same flow.

Most tools also let you check if a pattern fits well before cutting anything. You can view a garment in 2D or even in 3D models. That way, you reduce errors and make smarter decisions earlier.

Another key part is storage. With CAD, you can save and organize all your files in a secure way. You won’t waste time looking for that old version of a design.

Learn more: Discover 9 CAD tools to supercharge your fashion business

How does industrial CAD work in apparel production?

Industrial CAD helps clothing manufacturers work faster and with more accuracy. A good example is La Clofit, a fashion brand that used industrial CAD to grow.

Before using this technology, their team worked with paper patterns and spent hours on manual changes. After switching to Audaces solutions, they sped up their production process and improved the quality of their pieces.

Today, they launch collections faster and with more confidence. Check it out!

How is industrial CAD different from other technologies?

Think of CAD as the brain of your production. It guides each step by giving clear and accurate designs, playing a key role in both product design and industrial design.

When you combine CAD with other tools, your business becomes faster, more precise, and ready to grow. Each one has a job, and CAD is where it all begins.

Here are other technologies to make your production process complete:

CAM

CAM means Computer-Aided Manufacturing. It works after the design is ready. With CAM, you turn patterns from CAD into instructions for machines.

This helps you cut fabric automatically and with great precision. It reduces waste and speeds up production. Unlike CAD, which focuses on design, CAM takes care of the manufacturing steps.

Together, they form a complete digital path to success.

Learn more: 6 essential steps for choosing the perfect CAM technology

CNC

It stands for Computer Numerical Control. It’s the system that controls machines like automatic fabric cutters. These machines follow exact instructions created in CAD and CAM.

With solutions like Audaces Cutting Room, CNC technology allows for precise and fast cutting. This saves time and reduces errors during production.

CNC doesn’t create designs, it executes them. That’s why it needs CAD to provide the right digital patterns. Once the plan is ready, CNC makes it real.

This combination of tools leads to a smart, connected, and scalable production. You move from idea to garment with speed and quality.

ERP

ERP stands for Enterprise Resource Planning. It helps manage your business operations — like stock, sales, and orders. It’s a system for planning and control, not for design or cutting.

It works alongside it. While CAD supports design, ERP gives you a big-picture view of the company’s numbers and goals.

One of the biggest benefits of ERP is that it gives you data in real time. You know what’s in stock, what’s missing, and how each part of your factory is performing.

When you connect ERP with CAD and other tools, you create a smart factory. Each system helps in its own way, and together, they drive better decisions and faster results.

Learn more: Why should your company invest in fabrication technology?

Which processes can you automate with industrial CAD?

Pattern creation

With industrial CAD, creating patterns becomes faster. Everything happens on the screen, with digital tools made exclusively for fashion, saving time and improving accuracy.

You can create a new pattern from scratch or use a template. It’s easier to make changes, fix mistakes, and test ideas. This saves time and improves accuracy.

The software also helps you follow technical rules. You can add sewing lines, notches, and other details with just a few clicks.

Size grading

Size grading means creating different sizes from one base pattern. With industrial CAD, this job becomes faster. This is because the software lets you grade sizes automatically.

You choose the size rules, and the system applies them across the pattern. Still, it’s possible to check every change on screen and make quick adjustments. This avoids errors and makes sure every size fits as it should.

Automating grading saves hours of work and helps you deliver full-size ranges with more confidence.

Learn more: Discover the benefits of a pattern grading chart for your clothing production

Marker making

Marker making is the process of organizing pattern pieces on fabric. The goal is to use as much material as possible and reduce waste.

With industrial CAD, marker making becomes automatic. The system places each piece in the best position, quickly and precisely.

It checks fabric width, pattern direction, and other limits. You get the best layout without spending hours doing it manually. This means less fabric waste and more savings — a big win for your business.

Thinking about investing in this technology for your apparel business? Download our e-book and learn how automated marker making can transform your process!

Print placement

Placing prints on fabric is a delicate step. It must be exact, so designs match the final garment perfectly. By using industrial CAD, you can control this with digital tools. You can see how the print will look on each part of the pattern before production.

It’s possible to move, scale, or adjust the print to fit the style, avoiding mistakes and surprises later.

Learn more: All you need to know before investing in CAD/CAM system

How can you implement industrial CAD in your apparel business?

The first step is to choose the right software. Look for a solution made for the fashion industry. It should support pattern design, grading, marker making, and print placement.

Next, train your team. Learning how to use the system is key. For this, many companies offer support, tutorials, and onboarding tools to help you start fast.

Keep in mind that you don’t have to change everything at once. Begin with one part of your process, like pattern creation. Once the team feels confident, move on to grading and marker making.

It’s also important to review your current workflow. Connect your CAD system with other tools, such as cutting machines or ERP software, for better results.

When you take these steps, your industrial CAD technology implementation will be smooth and quickly bring great results!

Automate your production with Audaces industrial CAD

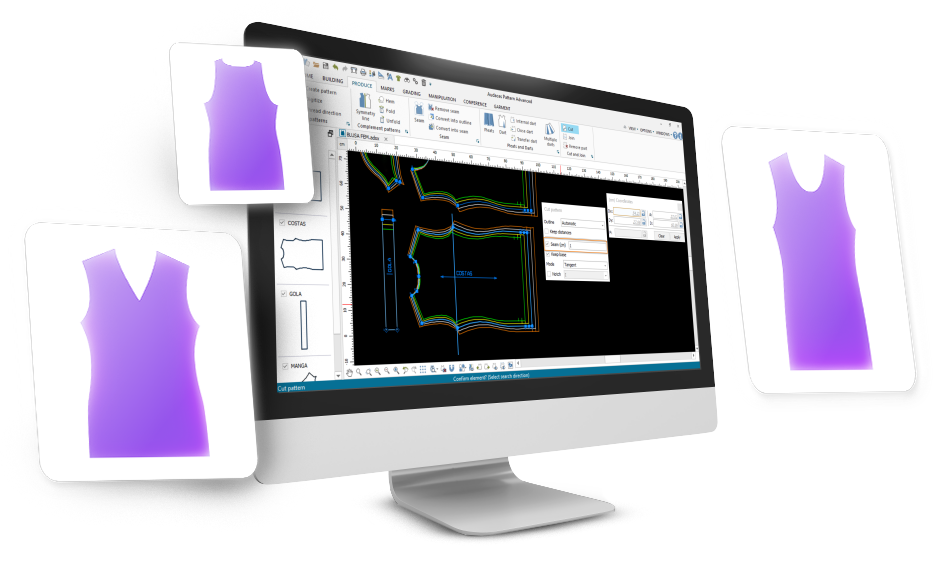

Audaces Pattern

For professionals looking for excellence, Audaces Pattern is the perfect solution. It ensures the pattern design reaches a new level of efficiency and precision.

With its versatile approach, it’s possible to develop high-quality patterns, regardless of complexity.

Refine every detail to perfection, ensuring that your creative vision translates into patterns. This advanced solution will assist you with all your pattern making endeavors!

Audaces Maker

Audaces Marker is the best solution to create markers for cutting fabric with perfection. We used the best technology to design it to improve the efficiency of the production process.

With this powerful ally, companies can lay out patterns in a way that reduces waste and makes the most of their raw materials.

It allows professionals to create markers more efficiently, saving both time and money.

Discover Audaces360 and unlock a world of possibilities for fashion design and production. Explore our comprehensive suite of solutions today!

FAQ

Industrial CAD can bring big results to your fashion business. It helps you improve how you design, create, and produce clothing. Instead of doing everything by hand, you can count on smart tools to speed up your work.

Industrial CAD means Computer-Aided Design made for fashion and textile companies. It’s a set of digital tools used to create, adjust, and manage patterns and markers.

They include processes like pattern creation, size grading, marker making, and print placement.