Summary

- System integration in fashion production streamlines processes and increases efficiency.

- Integrated solutions are key to enhance collaboration across design, pattern making, and production teams.

- Want to take your fashion business further? Subscribe to our newsletter for exclusive insights!

Today, apparel manufacturers face growing pressure to deliver high-quality collections quickly. All while managing costs and resources effectively.

In this scenario, system integration has emerged as a great strategy to meet these demands. It connects all stages of the manufacturing process into a seamless workflow. Designers, pattern makers, and production staff can all work together for productivity gains.

To learn how to take advantage of this competitive edge, explore the tips we’ve prepared. We’ve highlighted six key benefits to help you make smarter technology decisions for your company.

Happy reading!

Sumário

What is system integration?

System integration is the process of connecting different software and technologies, so they work together as a single solution. Instead of each system operating in isolation, integration allows them to communicate and share data seamlessly.

When systems work together, information flows automatically from one stage to another. For example, you can create a design in a CAD program and send it directly to production. All without manual adjustments or duplicate entries.

This reduces the risk of errors and ensures that all departments are working with the same updated data. The result is greater harmony across the entire operation.

By integrating tools, companies optimize their business processes and gain a clearer view of the entire production chain. Simply put, integration helps apparel companies save time and achieve higher productivity without sacrificing quality.

Why should apparel manufacturers rely on integrated systems?

Fashion is a complex industry that involves design, production, logistics, and distribution working in unison. When these areas depend on isolated information systems, teams can easily duplicate or lose data. This leads to inefficiencies that slow down production and increase costs.

Using multiple systems forces teams to cross-check information, wasting time and increasing the chances of error. Integration solves these issues by aligning different tools under a single, connected environment.

One of the greatest benefits is agility. Integrated systems allow data to flow instantly across departments. This means everyone has access to the same updated information. It’s the best way to improve collaboration and reduce confusion between teams and suppliers.

It’s about operational efficiency!

Learn more: Enhance productivity in sectors of the textile industry with technology

Which systems can you integrate in apparel manufacturing?

It’s possible to connect several solutions to build a more efficient workflow in fashion production. Each plays a role in different stages, but together they create a seamless ecosystem.

Collection planning systems

Collection planning is the foundation of apparel production. By integrating a PLM with an ERP system, companies can manage timelines, budgets, and product mix more effectively. The connection between planning and enterprise resource planning (ERP) ensures the alignment of collection data.

A centralized platform makes collaboration easier, giving teams a shared view of the entire collection strategy. It also reduces errors caused by manual data entry. Once you insert information in one system, it automatically flows into the other.

Learn more: How can you choose the best PLM software for your business?

2D and 3D design systems

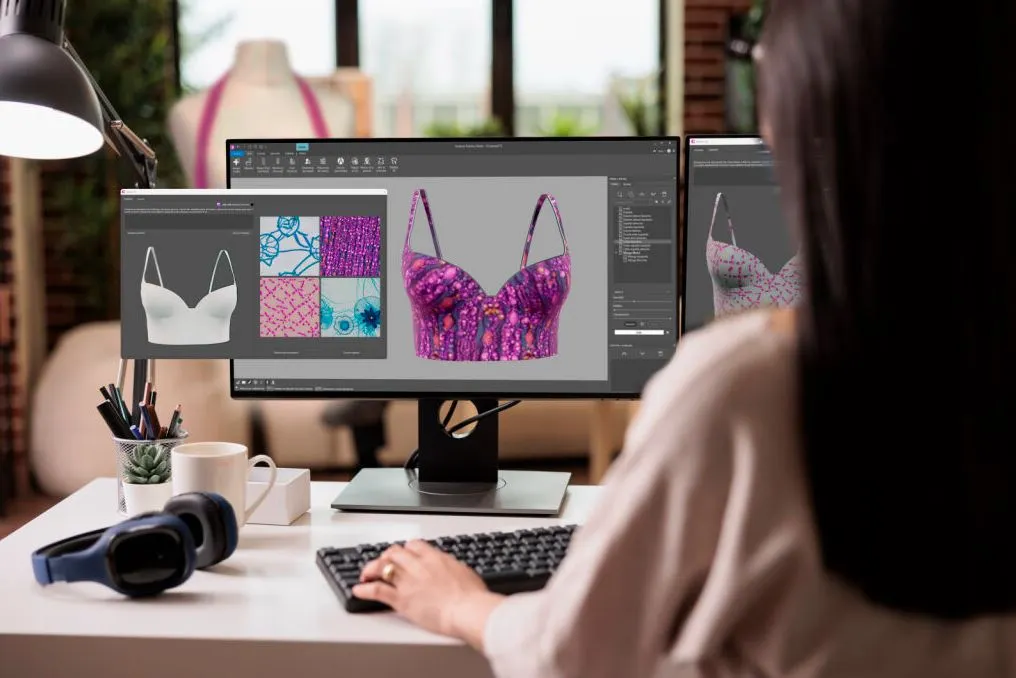

Design is at the heart of fashion, and integrating 2D and 3D systems transforms the creative process.

With digital tools, you can develop sketches and prototypes quickly, test them virtually, and make changes in real time. This reduces the need for physical samples, saving both fabric and time.

The integration also improves communication between design and production. Instead of handing over static drawings, designers can share 3D simulations that show how garments will look and fit.

Clients and buyers also benefit from 3D visualization. They can see collections before production begins, making it easier to approve designs.

Learn more: Top tips to pick the best pattern design software for you

Pattern and marker making systems

Integrating a pattern system with marker making software allows companies to optimize fabric use and ensure perfect fits. This connection guarantees you’ll develop every size and variation in the most cost-effective way.

Integration also eliminates the gap between design and production. You can send your patterns directly to marker making without conversions or adjustments, reducing delays.

Moreover, marker making systems optimize fabric placement, reducing waste and cutting costs. With a pattern system, they provide seamless transition from garment design to fabric layout, maximizing efficiency at scale.

Learn more: 4 reasons to create automatic marker on the computer

Cutting systems

Cutting is a critical stage where precision directly impacts quality. Integrated cutting systems receive data from marker making software automatically. This reduces the risk of errors and ensures accuracy down to the millimeter.

The connection speeds up production, as operators no longer need to manually program cutting instructions. Automated data transfer ensures every piece is according to plan, saving time and avoiding material waste.

Management systems

Management systems provide a bird’s-eye view of the entire operation. When integrated with other solutions, they allow managers to monitor progress, control costs, and identify bottlenecks in real time.

It ensures that you make decisions with accurate and up-to-date information. From resource allocation to delivery schedules, managers have full visibility and control, which reduces risks and improves responsiveness.

Ultimately, connecting management systems with the rest of the production workflow empowers apparel companies to operate strategically. It guarantees every department works toward the same goals.

Worried about implementing new technology in your production? Don’t be! Discover how to do it smoothly while keeping your operations running. Download our resource to learn more!

Benefits of system integration for your fashion business

By connecting systems, fashion companies create a smoother, more efficient workflow. Integration helps each stage of production communicate with the next. Discover how!

1) Improved communication between different teams

Clear communication drives fashion manufacturing forward. When systems stay disconnected, teams often work with conflicting information.

With system integration, designers, pattern makers, and production managers share files and updates instantly without endless emails.

It also strengthens relationships with suppliers and partners. Teams deliver accurate information faster, which reduces delays and builds trust.

As a result, communication stays clear, direct, and consistent. Everyone knows what to do and when, keeping operations smooth across the entire business.

2) Faster processes

System integration cut delays by removing unnecessary steps and speeding up the flow of information between departments. Instead of re-entering the same data in multiple tools, integration moves information automatically to the next stage.

Automated processes also reduce waiting. Once markers are ready, cutting instructions go straight to machines without human intervention.

It keeps production cycles fast and agile, giving companies a strong advantage in a competitive market.

3) Less rework

Rework wastes valuable time and resources in apparel manufacturing. Most errors happen when teams enter information incorrectly or lose data between disconnected systems.

One of the main benefits of system integration is that it keeps data accurate as it flows from one stage to the next. Teams no longer duplicate entries or adjust incompatible files. With fewer errors, rework drops, companies save materials, reduce labor waste, and avoid delays in deliveries.

Learn more: How can technology enhance the quality of textile products?

4) Higher productivity

With systems working together, teams spend less time on repetitive tasks and more time on activities that add real value. In addition, managers can generate real-time dashboards instead of building reports manually.

It also prevents downtime. Production can keep working without interruptions caused by missing data, unclear instructions, or incompatible tools.

This steady flow boosts output across the operation, enabling companies to meet growing demand without raising costs.

5) Complete and real-time visibility

This is the dream of every manager and business owner coming true: full visibility of the process. Now, it’s possible to track every stage of production in real time, from design to delivery.

With this transparency, teams spot problems early. They react quickly to material shortages, production delays, or design changes.

Complete visibility lowers risks and builds confidence. Leaders act with a clear picture of the business instead of relying on assumptions.

6) Smarter decision-making

Strong decisions require strong information. That’s why system integration centralizes data, making it easy to analyze and apply to strategy. You can identify trends, forecast demand, and allocate resources more effectively. Integration removes guesswork and strengthens long-term planning.

Leaders also compare performance across departments in real time. You can adjust quickly to make smarter decisions, leading directly to better outcomes. Companies reduce costs, increase speed, and launch stronger collections because integration keeps everything connected.

Learn more: Why should your company invest in fabrication technology?

Integrate your apparel business with the Audaces360 all-in-one platform

Nothing beats a real example to show how system integration works in practice!

Alpenplus, an Italian outdoor brand with 12 years of expertise, chose Audaces360 to boost their productivity. With its connected solutions, they gained greater control over collection development and streamlined communication with suppliers.

Want to see the results? Watch the full video!

Audaces360

Audaces360 integrates cutting-edge digital innovations to optimize workflows in the textile and apparel industry.

It caters to companies of all sizes and types, offering the flexibility to scale with your business needs.

All solutions were carefully developed to address the specific challenges of the field. They streamline the design and production processes, saving valuable time and resources.

The platform boasts a comprehensive range of functionalities, including pattern making, marking, collection management, vector drawing, and 3D creation.

In addition, a fashion Artificial Intelligence to assist you along the way.

Discover Audaces360 and unlock a world of possibilities for fashion design and production. Explore our comprehensive suite of solutions today!

FAQ

System integration is the process of connecting different software and technologies, so they work together as a single solution.

Some examples of integration include systems for collection planning, 2D and 3D design, pattern and marker making, cutting, and management.

Improved communication between teams, faster processes, less rework, higher productivity, and smarter decision-making.