Summary

- Wholesale clothing manufacturing involves the large-scale production of garments

- Clothing is produced in large quantities for retailers’ demand in wholesale clothing

- Explore cost-effective management of your collection with Audaces360 multi-solution!

The production processes of clothing wholesale and retail differ significantly, spanning from the preparation of garments to manufacturing speed and quantity.

Understanding these distinctions and their impact on sales is crucial for a successful journey in the fashion industry.

In this article, we’ll address all your questions about clothing wholesale and how Audaces can streamline this process while reducing costs.

Enjoy your read!

Sumário

How does wholesale clothing production operate?

Wholesale clothing manufacturing encompasses the large-scale production of garments intended for retailers or distributors.

Typically, this process is conducted by clothing manufacturers with the necessary capabilities and resources to generate substantial quantities of products.

To establish a successful wholesale clothing business, it’s essential to follow several key steps:

Design and development

The production process initiates with the creation of clothing designs. Manufacturers may employ in-house designers or collaborate with stylists and brands to conceptualize garment models. During this phase, prototypes and samples are crafted for approval before initiating mass production.

Learn more: How can fashion brands boost their business with technology?

Raw material acquisition

Clothing manufacturers procure the materials essential for production, including fabrics, buttons, zippers, threads, and other accessories. These materials are acquired from various suppliers or through strategic partnerships.

Learn more: Discover the challenges in the textile industry’s supply chain and how to overcome them

Cutting and sewing

Fabrics are meticulously cut into patterns according to the garment design. These pieces are then expertly sewn together to form complete clothing items. This sewing process can be carried out manually or using industrial sewing machines.

Finishing

Once the clothing is sewn together, it undergoes a finishing stage. This phase involves the application of buttons, zippers, labels, embroidery, prints, or any other specific design elements. It also includes a comprehensive quality inspection to ensure that the components meet the desired standards.

Packaging

The finished clothing items are packaged individually in plastic bags or boxes, depending on the type and size of the product. Typically, product labels are affixed, providing essential data and product identification.

Shipping and distribution

The garments are then dispatched to the retailers or distributors who have purchased them in bulk. Transport can be facilitated through transportation companies or logistics firms to ensure efficient distribution.

Key differences between wholesale and retail clothing

There exist notable disparities between wholesale and retail clothing manufacturing that become evident throughout their production and distribution processes. Let’s explore these distinctions:

Production quantity

Wholesale clothing is characterized by large-scale production, driven by the need to fulfill retailer demands. Consequently, larger production batches are the norm.

In retail, clothing is procured in smaller quantities, tailored for direct sales to individual consumers.

Customers

Wholesale clothing caters to retailers, distributors, or resellers who purchase clothing in substantial quantities for resale purposes, often through various retail channels, such as physical stores, boutiques, or e-commerce platforms.

In retail, the end consumers are the customers, purchasing clothing for personal use.

Pricing

Wholesale clothing purchasers enjoy lower prices per unit due to the substantial quantities they buy, with manufacturers offering discounts for bulk purchases.

In retail, clothes are sold at final prices, encompassing profit margins for the retailer.

Customization

Wholesale manufacturing centers on producing clothing in standardized styles, colors, and sizes to cater to a broad customer base. Customization is typically limited to facilitate mass production.

In retail, clothing can be more personalized, offering customization options to meet individual consumer preferences.

Logistics

In wholesale clothing, logistics play a pivotal role in efficiently distributing products to retailers, necessitating careful management of product delivery to designated locations.

Retail primarily focuses on logistics that facilitate direct delivery to individual consumers, be it through physical stores or e-commerce platforms.

Negotiation

Wholesale clothing transactions involve commercial agreements between manufacturers and retailers, encompassing discussions on pricing, delivery schedules, payment terms, and other contractual arrangements.

Retail negotiations revolve around interactions between the retailer and the end consumer, emphasizing one-to-one sales and personalized customer service.

Learn more: Discover step by step how to set up a fashion e-commerce

What to consider for a successful wholesale clothing business?

To achieve success in the realm of clothing wholesale, several critical aspects demand your attention.

These encompass providing exceptional customer service, cultivating strong relationships with your buyers, and remaining adaptable to shifts in the market.

Staying informed about industry trends, introducing innovative products and services, and embracing new opportunities are equally pivotal. Ultimately, the triumph of a clothing wholesaler hinges on a synergy of strategic planning, efficient execution, and a profound understanding of the market it operates within.

Let’s see each of these essential functions:

Market analysis

Conduct thorough research within the wholesale clothing sector, scrutinizing trends, assessing demand, analyzing competition, and pinpointing lucrative opportunities.

Grasp the ideal customer profile, delving into their preferences and needs. This understanding will define your value proposition and guide your business strategies.

Marketing plan

Forge a comprehensive marketing plan designed to promote your clothing wholesale business.

Identify the most effective communication channels for reaching your target audience, such as online advertising, participation in industry exhibitions, influencer marketing, or direct marketing.

Consider establishing a website or e-commerce platform to display your products and facilitate direct sales to buyers.

Operational plan

Outline a robust operational plan addressing elements like supplier relationships, supply chain management, large-scale production, storage, and logistics.

Ensure you establish reliable suppliers and institute processes that guarantee the timely production and delivery of products.

Implement a rigorous quality control system to ensure that your clothing meets the desired standards.

Financial plan

Craft a comprehensive financial plan encompassing income and expense projections, cash flow management, and pricing strategies.

Scrutinize costs related to production, storage, transportation, marketing, and personnel. Furthermore, assess your pricing strategies to ensure competitive profit margins.

Also, regularly monitor your company’s financial health, track key performance indicators, and make necessary adjustments as circumstances evolve.

How to increase production and become a clothing wholesaler?

Ramping up production and transitioning into a clothing wholesaler role necessitates meticulous planning and the effective implementation of various strategies. Here are some key steps:

Assess your current capacity

Before embarking on production expansion, evaluate your existing capacity, encompassing factors such as facilities, equipment, labor, and financial resources. Plus, identify areas that require enhancement or enlargement to accommodate larger-scale production.

Improve operational efficiency

Seek opportunities to enhance efficiency within your manufacturing processes. This entails the adoption of advanced technologies, automation of specific tasks, workflow redesign, and optimization of factory layouts.

By reducing cycle times, optimizing resource utilization, and minimizing waste, you can significantly boost production.

Learn more: How to define production stages using a textile flowchart

Strengthen the supply chain

Ensure the stability and reliability of your supply chain.

This involves selecting dependable raw material suppliers, fostering enduring relationships with them, and negotiating advantageous agreements regarding price, quality, and delivery schedules.

Expand production capacity

If necessary, contemplate the physical expansion of your facilities. This might involve securing additional space, constructing new facilities, or outsourcing production to trusted partners.

It’s vital to align your expanded production capacity with the prevailing market demand.

Invest in training and development

Provide comprehensive training to enhance your employees’ technical skills and prepare them to manage increased workloads.

Training should cover equipment operation, quality management, inventory control, and other pertinent areas.

Establish strategic partnerships

Explore the possibility of forming strategic partnerships with other manufacturers or companies in the textile sector.

These conncetions could involve agreements to share resources, production capabilities, or technical expertise.

Such collaborations facilitate the expansion of your production capacity without the need for physical facility expansion.

Develop a distribution network

Craft a robust distribution strategy aimed at reaching a broader array of retailers or distributors.

Identify business partners who can assist in the distribution of your products across diverse geographic regions or sales channels.

Cultivate strong relationships with buyers and guarantee the efficient and punctual delivery of products.

Monitor and adapt to market trends

Stay vigilant regarding market changes and trends: track shifts in consumer preferences, seasonal demands, and emerging business opportunities.

Be prepared to adapt your production processes to meet the evolving needs of buyers.

Enhance your wholesale clothing production with Audaces360

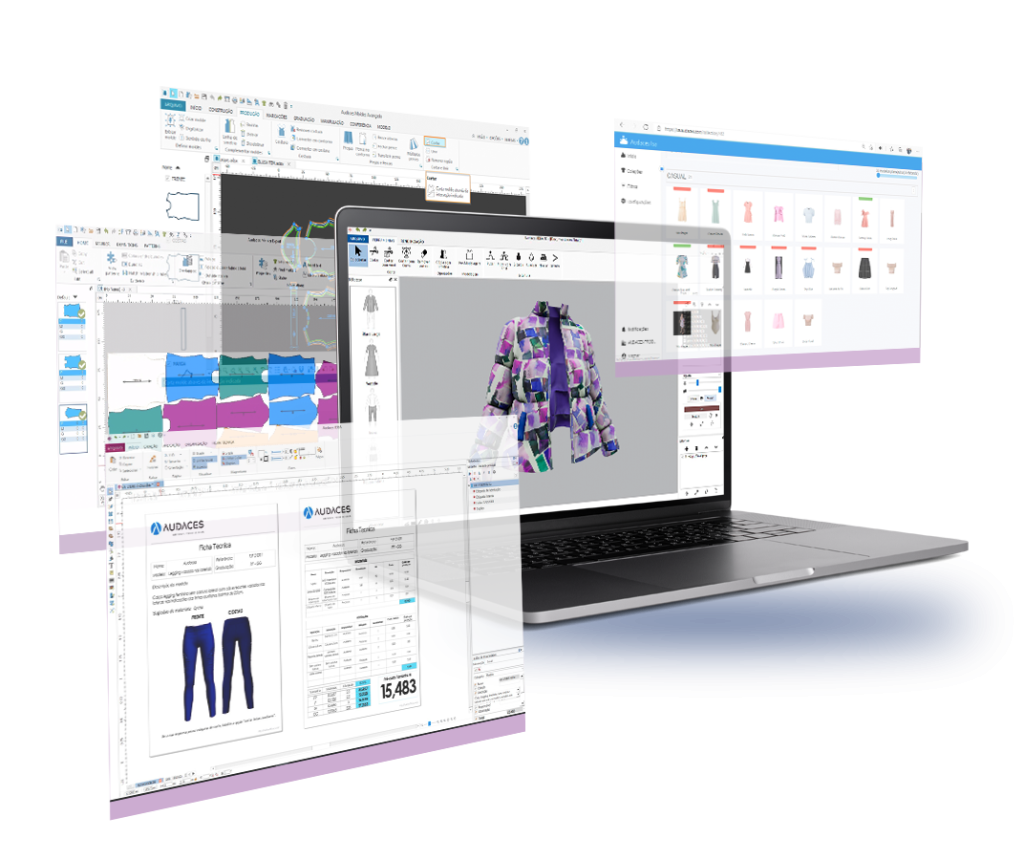

Audaces360 is a specialized software solution tailored for the textile and clothing industry. Its primary aim is to enhance and expedite the clothing production process.

With features for both 2D and 3D design, it empowers users to visualize garments before production begins, offering valuable insights into the creative process.

Audaces360 provides a comprehensive overview of the entire garment manufacturing process, from cutting to sewing and finishing. By offering a well-defined roadmap, it enables businesses to optimize workflows, prevent delays, and ultimately increase productivity.

In the world of clothing wholesale, this multi-solution can be a game-changer, helping companies meet production demands efficiently.

If you’re considering entering the clothing wholesale industry, check out our free e-book with insights and guidance for eliminating invisible costs when opening your business:

FAQ

Wholesale clothing production is typically executed by clothing manufacturers with the capabilities and resources required for large-scale production.

The primary distinction lies in the production scale. Wholesale clothing involves large quantities destined for retailers, while retail production caters to smaller quantities for end consumers.

Offering excellent customer service, adapting to market dynamics, staying current with industry trends, fostering innovation in products and services, and embracing new opportunities.

One Response

Thank you for this insightful article! Discovering cost-cutting strategies in wholesale clothing production is a game-changer. The tips provided here are not just practical but also revolutionary. Implementing these ideas will undoubtedly enhance efficiency and profitability in the industry. Grateful for sharing such valuable insights!