The most advanced automated cutting technology for the fashion industry.

Our equipment uses cutting-edge technology to optimize material usage and ensure faster and more efficient production, reducing costs and maximizing your results.

Easy to use and adaptable to any production scale, Audaces Cutting Room is your ally for achieving more in less time, with flawless results.

Embrace innovation and take your business to the next level!

Audaces Cutting Room is more than an ally in your production — it’s a revolution.

Automate your production process, reduce errors, and optimize resources by fully integrating Audaces ICF and other software from the Audaces360 suite, including Audaces Pattern and Audaces Marker.

Every detail counts. Every garment is perfect.

Increase your efficiency with an automatic cutting machine

Accelerate production by scheduling different spreads on the same day

Expand your production capacity with practical spreading

Manage and monitor your cutting room in real time

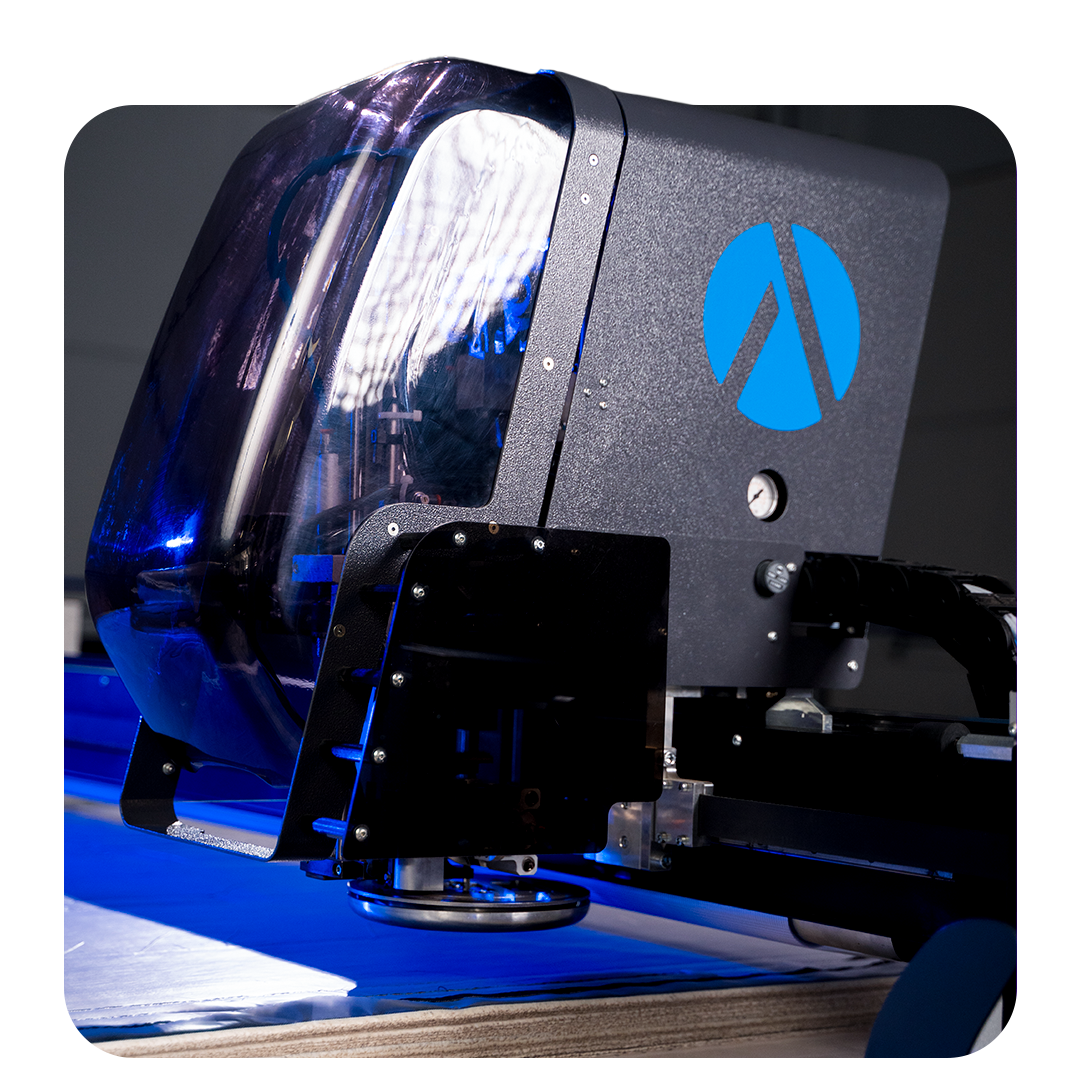

The Audaces cutting machine is an automated equipment used in the fashion industry to cut fabrics with speed and precision.

It uses advanced technology to ensure precise cuts, reducing material waste and increasing efficiency.

The cutting table acts as a base for positioning the fabric, allowing the machine to cut the desired shape, optimizing the production process.

The Audaces Cutting Room is equipped with: Audaces Neocut Bravo (automated cutting machine), Audaces Linea (automatic spreading machine), and Audaces Pratica (extension table).

hese pieces of equipment, along with Audaces ICF cutting management system, help cut fabric faster, with fewer mistakes, and less waste.

The Audaces automated cutting process starts by creating a digital pattern (for example, using Audaces Pattern). Then, the pattern is imported into software (such as Audaces Marker), where the pieces are arranged to maximize fabric usage.

Once the cutting machine is set up, the fabric is cut automatically with great precision, following the digital patterns. This leads to higher efficiency, better quality, and less waste in production.

The Audaces automated cutting room offers several advantages, including increased efficiency and precision in fabric cutting.

Automation also enables faster and more consistent cutting. In addition, technology can streamline integration with other processes in the production chain, such as inventory planning and control.

The price of Audaces Cutting Room depends on the specific configuration and additional services selected.

To receive a personalized proposal and explore payment options, get in touch with an Audaces consultant.

Audaces ICF is an intelligent cutting management system for the textile industry.

It integrates and optimizes the fabric cutting process, increasing efficiency, reducing material waste, and improving productivity.

Audaces ICF enables centralized control over all cutting process stages, resulting in higher precision and savings in resource usage.

Monday to Friday, from

8 AM to 5:30 PM, except holidays.